Automatic stick-inserting mechanism for meat string

An automatic, meat skewer technology, applied in the direction of processed meat, meat processing equipment, slaughtering, etc., can solve the problems of difficult to meet food hygiene standards, difficult to control the weight of a single skewer, and high labor intensity, and achieve simple structure and high work efficiency , flexible and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

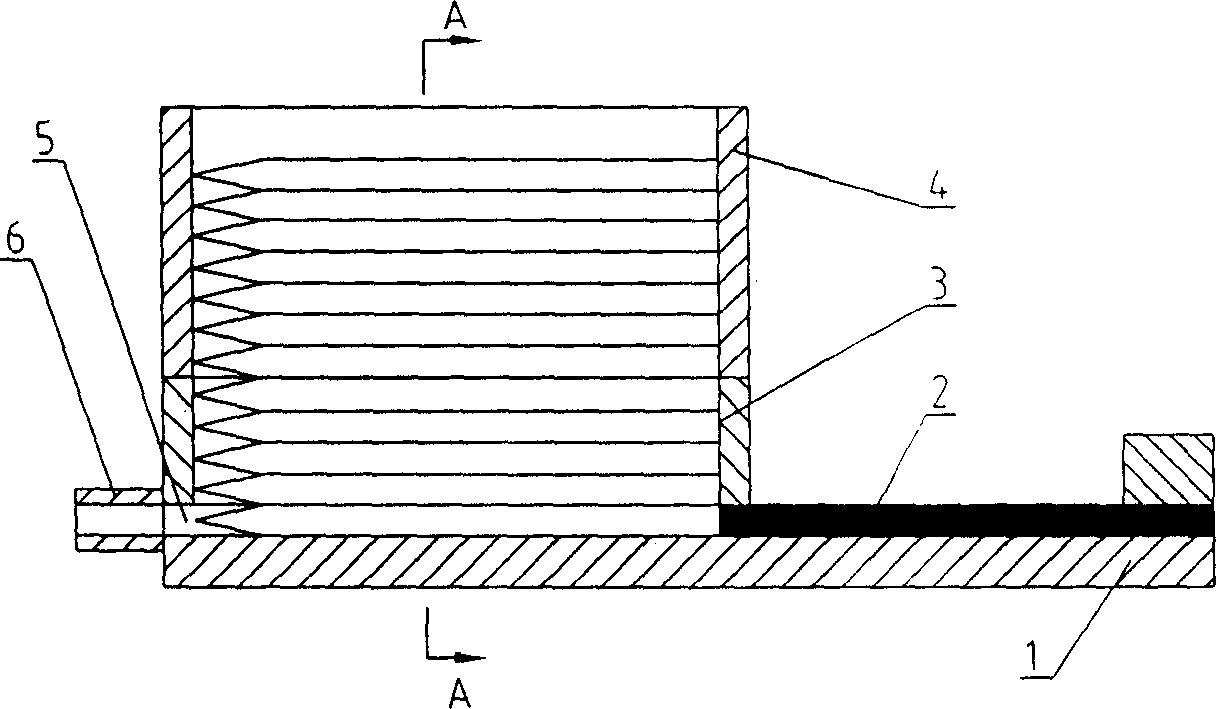

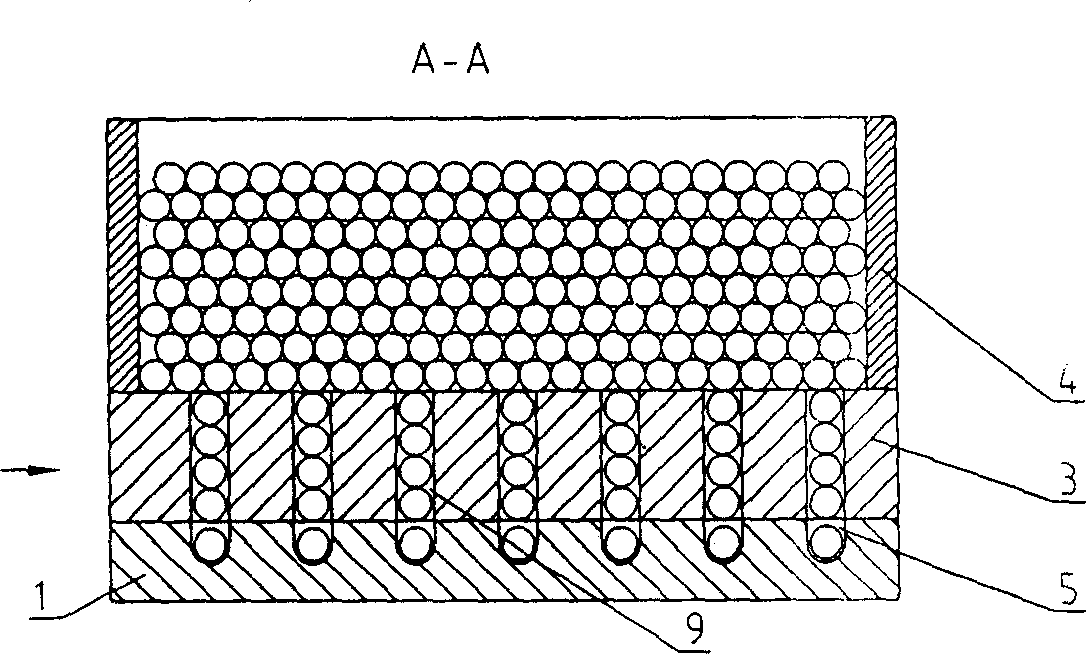

[0014] The composition of the meat skewer automatic insertion mechanism includes a signing bucket 4, a pressing plate 3 is arranged under the signing bucket, a guide plate 1 is arranged under the pressing plate, a row of guide grooves 9 is opened on the guide plate, and a row of quantity and spacing and the distance between the guide grooves are opened on the pressing plate Equal to the number of lottery holes 5, the pressing plate is flexibly connected with the guide plate and the lottery bucket, and one end of the guide plate is a lottery hole, and the other end is provided with a sign pushing lever 2. A guide head 5 is set at the sign-out hole, and the guide groove and the lot-drop hole are equidistantly distributed, and the bottom of the guide groove is "U"-shaped, and the number of the guide groove and the lot-drop hole is generally 1-12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com