Method for preparing flat ruche with large crystalline host lattice perforated twin-shaft mesh structure

A technology of warp knitted fabric and shaft net, applied in warp knitting, flat warp knitting machine, knitting and other directions, can solve the problems of reducing the knitting speed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

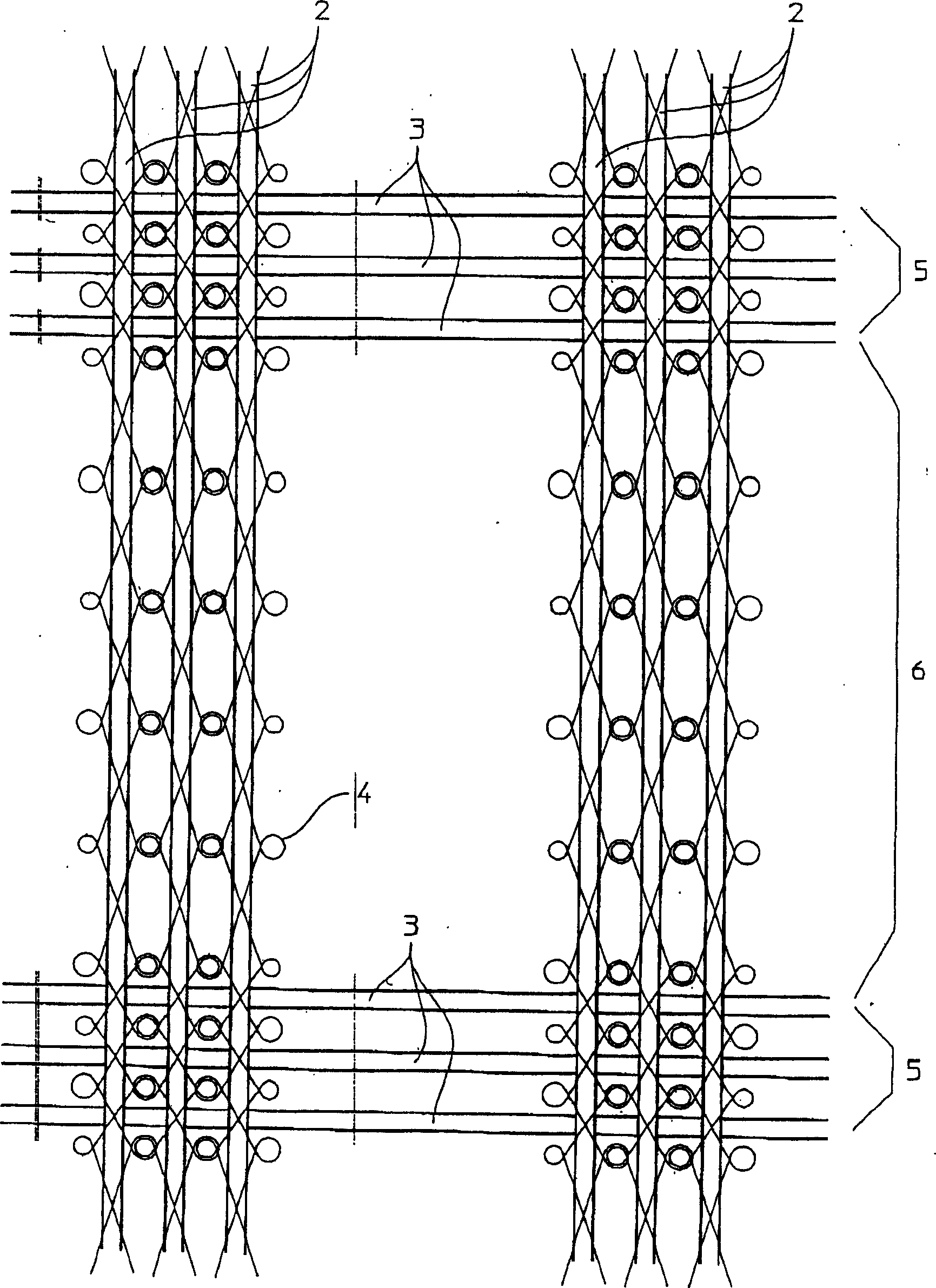

[0034] figure 1 A schematic top view of a lattice-shaped warp-knitted fabric. The lattice 1 is formed from groups of 2 warp threads which lie against weft threads 3 likewise arranged in groups.

[0035] The loops of fixed yarn 4 extend along warp yarn 2, at figure 1 The fixed yarns are shown with large zigzag lines and small circles in .

[0036] The mesh size in the intersection area 5 of the warp yarn 2 and the weft yarn 3 is smaller than the mesh size in the area of the lattice hole 6 . The idea of the design of the present invention is that the required mesh size in the intersecting range 5 constituting the connection point is smaller than the mesh size in the lattice opening 6, so that each warp yarn and the ground warp are fixed to each other.

[0037] The size of the loops of the fixed yarn 4 simultaneously constitutes the dimension of the entire geometric lattice 1 design. The meshes of the geometrical lattice are called macropores, since the mutual spacing bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com