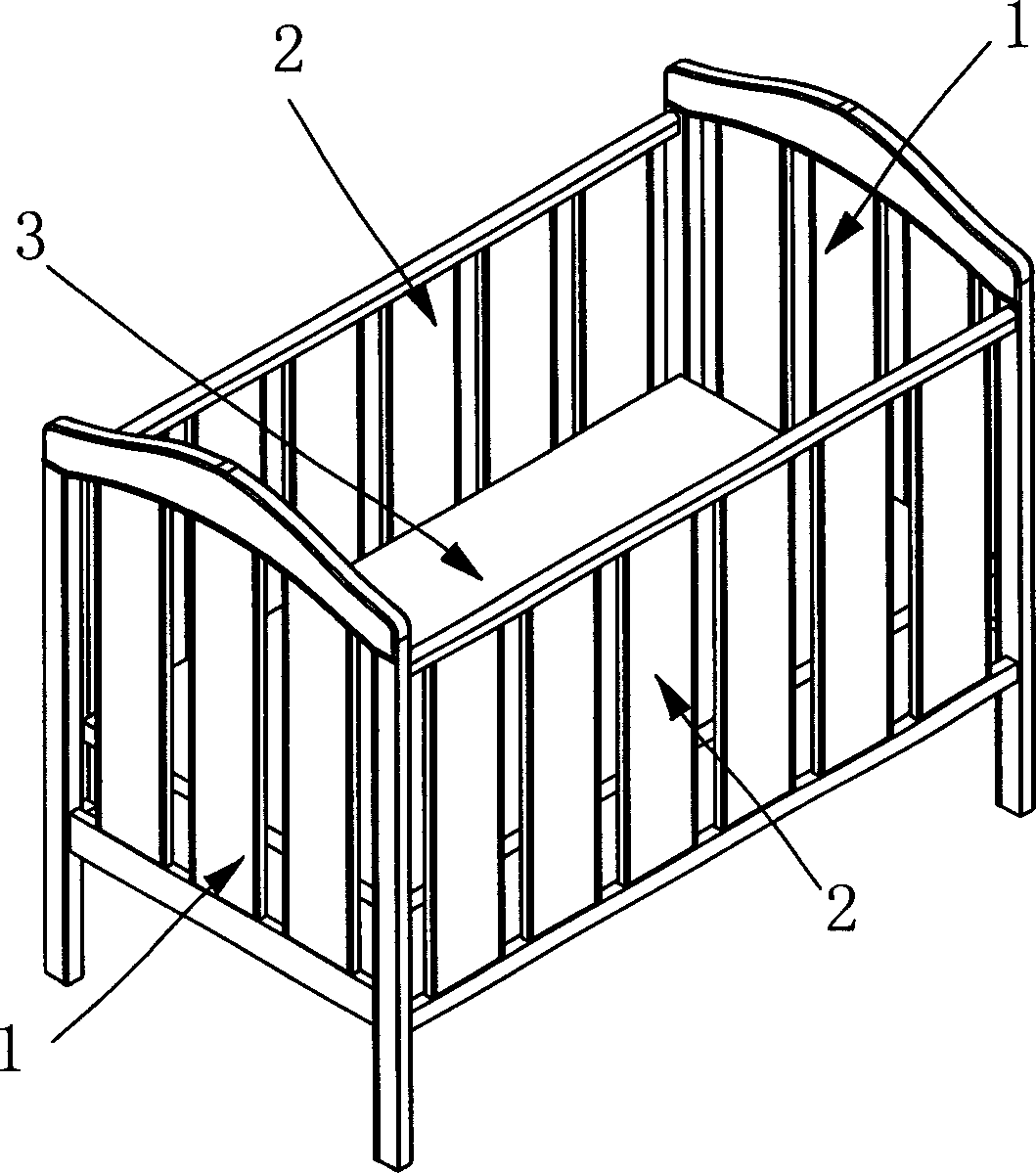

Combined children's bed

A crib and composite panel technology, which is applied in the field of cribs, can solve the problems that plastic panels cannot bear large gravity, inconvenient connection of cribs, and low connection strength, etc., and achieve the effect of light weight, small space occupation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0063] The difference between this embodiment and the first embodiment is that the longitudinal side frame 1 adopts the following structure: the longitudinal side frame 1 includes two outrigger frames, a first upper beam, a first lower beam and three first auxiliary brackets. The first upper beam is fixedly connected to the upper ends of the two outriggers; the first lower beam is fixedly connected to the middle of the two outriggers; and the three first auxiliary brackets are uniformly and fixedly connected between the first upper beam and the first lower beam.

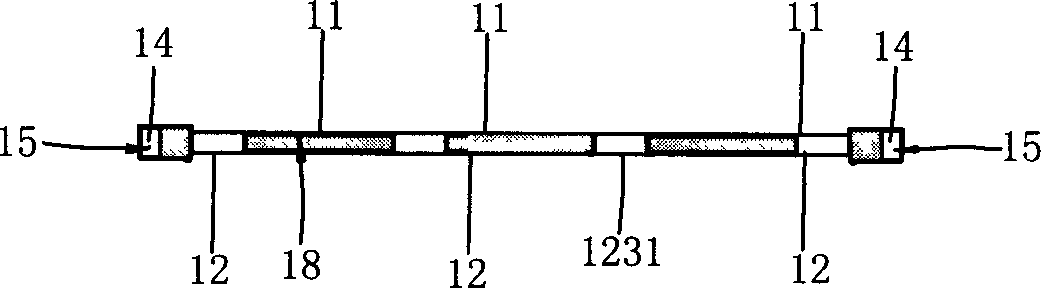

[0064] Among them, the two outrigger frames, the first upper beam, and the first lower beam are the third plastic composite board, and the third plastic composite board is a plastic composite board, which includes a panel, a chassis, a honeycomb panel and an inner lining, and a honeycomb panel It is filled between the face plate and the bottom plate, and the inner liner is sandwiched between the face plate and the bot...

Embodiment 3

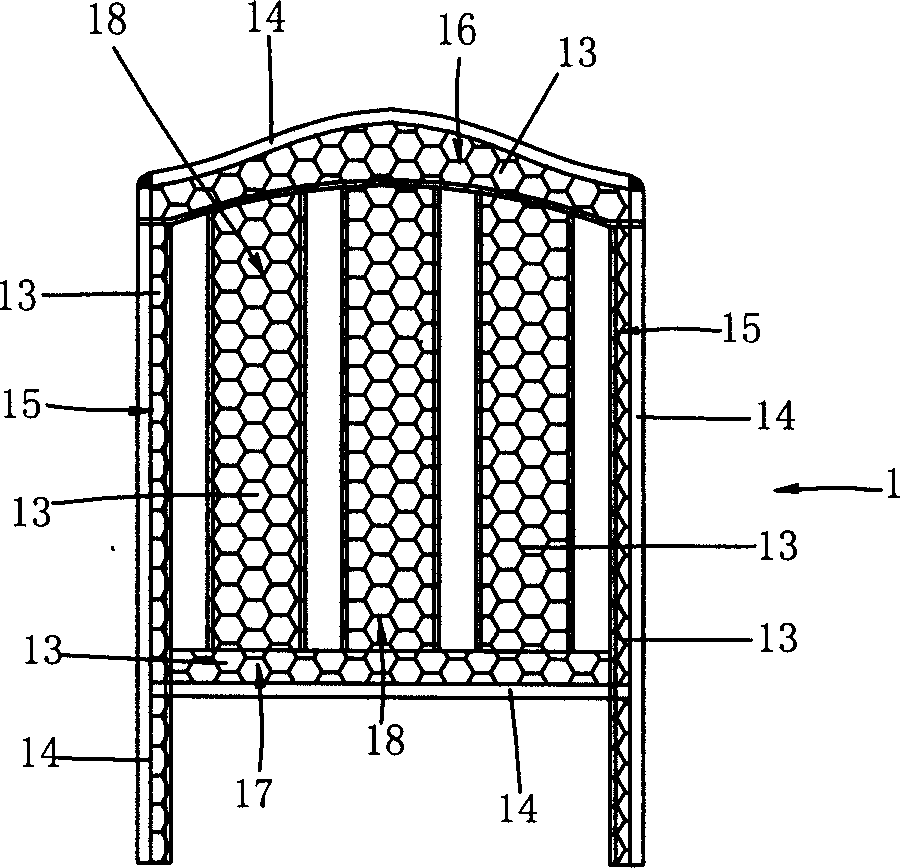

[0070] This embodiment differs from Embodiment 1 in that: Figure 11 , 12 , 13, 14, and 15, the two longitudinal side frames 1 are the first plastic composite board, which includes the first panel, the first bottom plate, and the first honeycomb 13, and the first panel and the first bottom plate form two leg frames and connect In the connecting frame between the two outriggers, the first inner lining 14 made of hard material is arranged in the two outriggers and the connecting frame, and the first inner lining 14 is set in the first plastic composite board. Fill the first honeycomb 13;

[0071]Both lateral frames 2 include two second plastic composite panels and seventeen hard auxiliary rods 29, and the second plastic composite panels include a second panel 21, a second bottom plate 22, a second honeycomb 23 and a second lining 24, The second panel 21 and the second bottom plate 22 form an outer peripheral plate, and the outer peripheral plate is filled with a second honeyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com