Incrustation sediment retardation device

A fouling device and fouling technology, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems affecting efficiency and operation cycle, and rapid growth of reactor pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

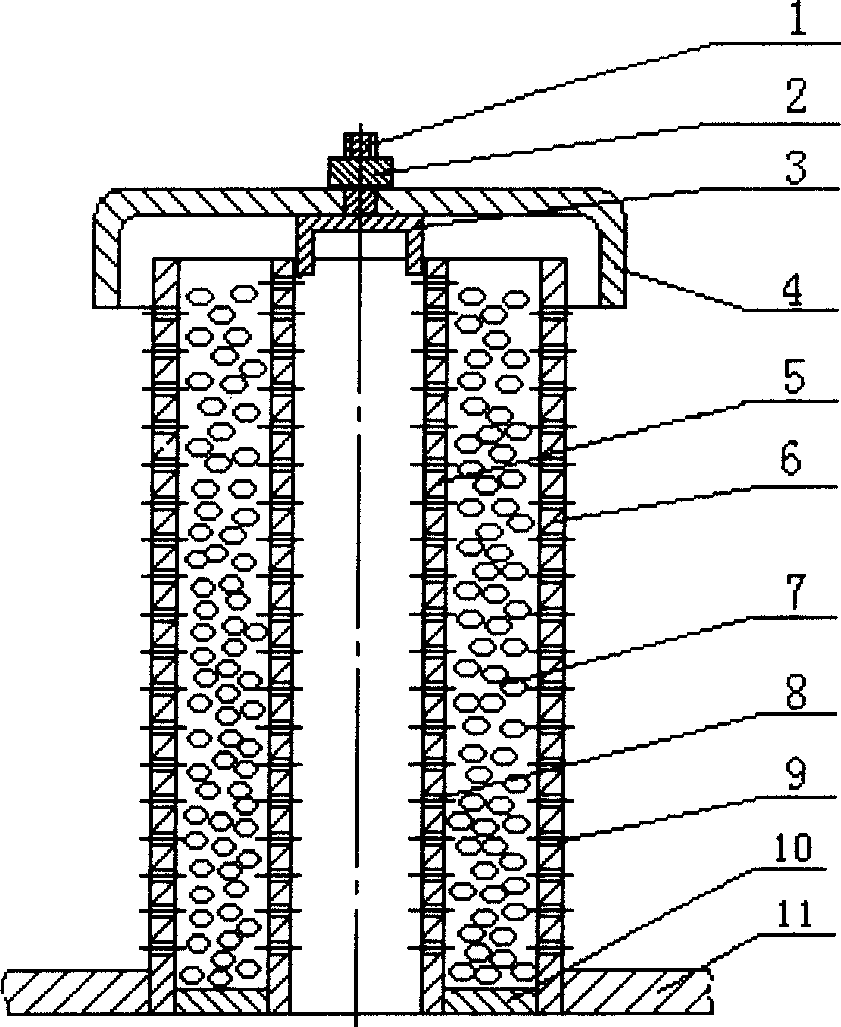

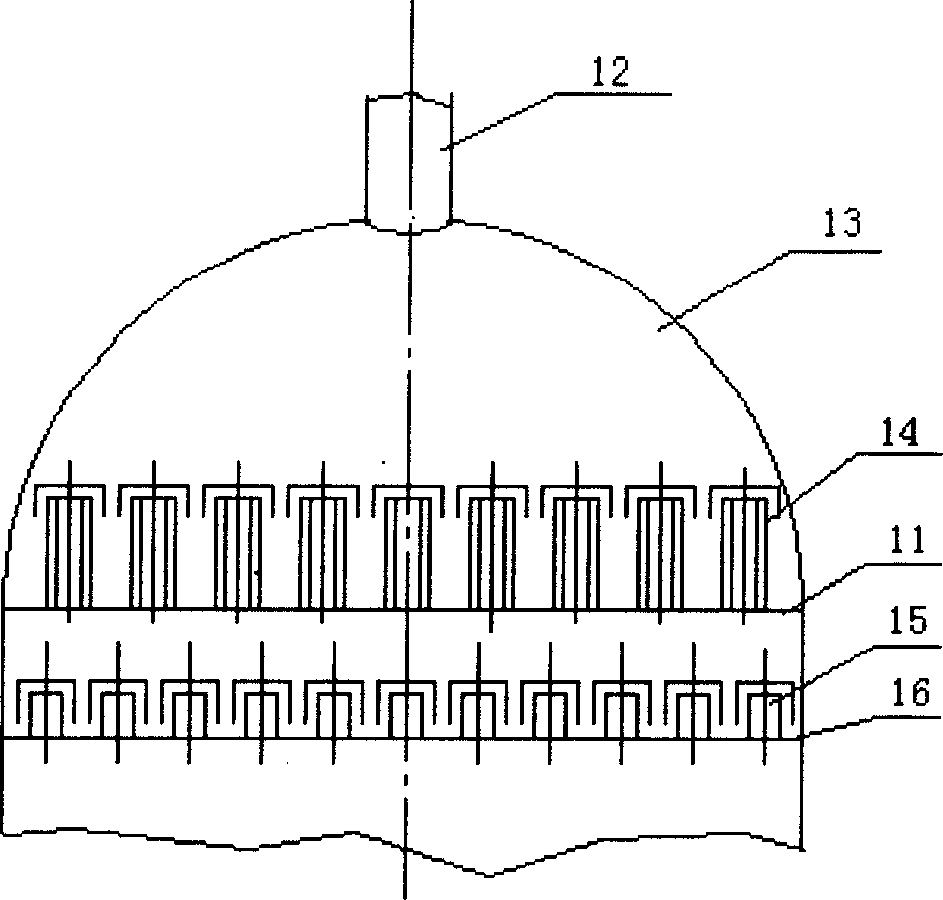

[0014] A delay fouling device with a typical structure of the present invention and its mode of operation will be further described below in conjunction with the accompanying drawings.

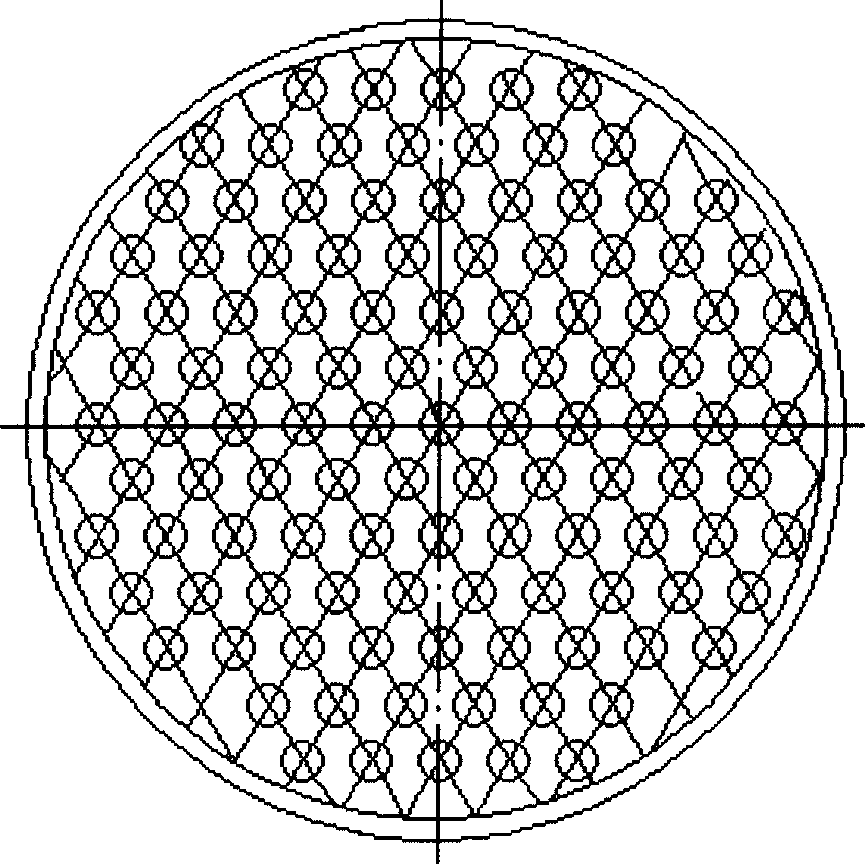

[0015] Such as figure 1 As shown, the delay fouling device of the present invention is composed of connecting bolt 1, connecting nut 2, connecting frame 3, baffle cap 4, fouling device inner cylinder 5, fouling device outer cylinder 6, protective agent or filler 7, sealing bottom plate 10 and so on. Wherein the fouling device inner cylinder 5, the fouling device outer cylinder 6 sides are evenly distributed with small round holes 8, 9, the protective agent is housed between the fouling device inner cylinder 5 and the fouling device outer cylinder 6, the top of the baffle cap 4 The central hole is provided with the connecting frame 3 through bolts, the connecting frame 3 is welded to the inner cylinder 5 of the fouling device, the connecting frame connects the baffle cap and the fouling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com