Method for producing injection-molded and in-mold decorated article and mold for injection molding with in-mold decoration

A technology of injection molding and manufacturing method, which is applied in the direction of coating, etc., and can solve the problems of resin burn, shape and layout restrictions of molding space part 503 and auxiliary space part 504, and easy occurrence of fusion lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

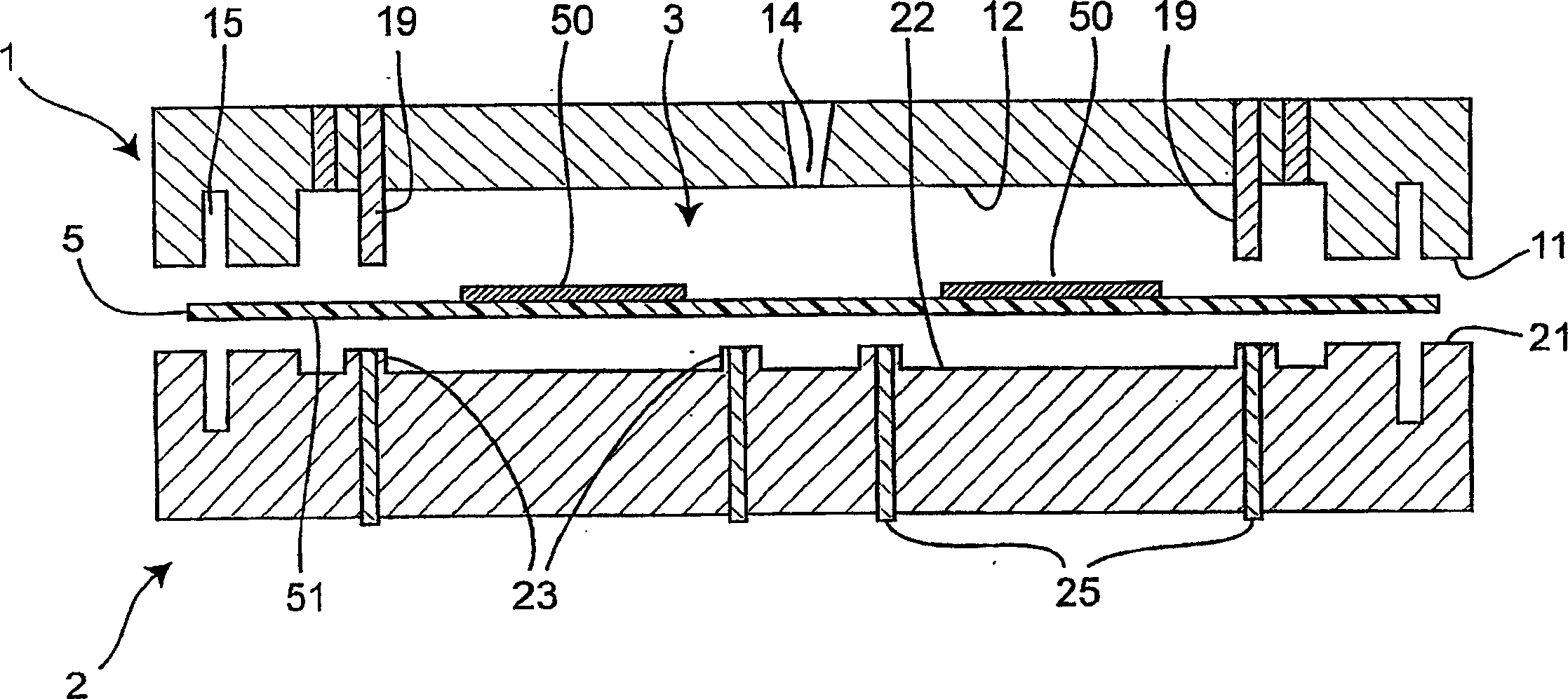

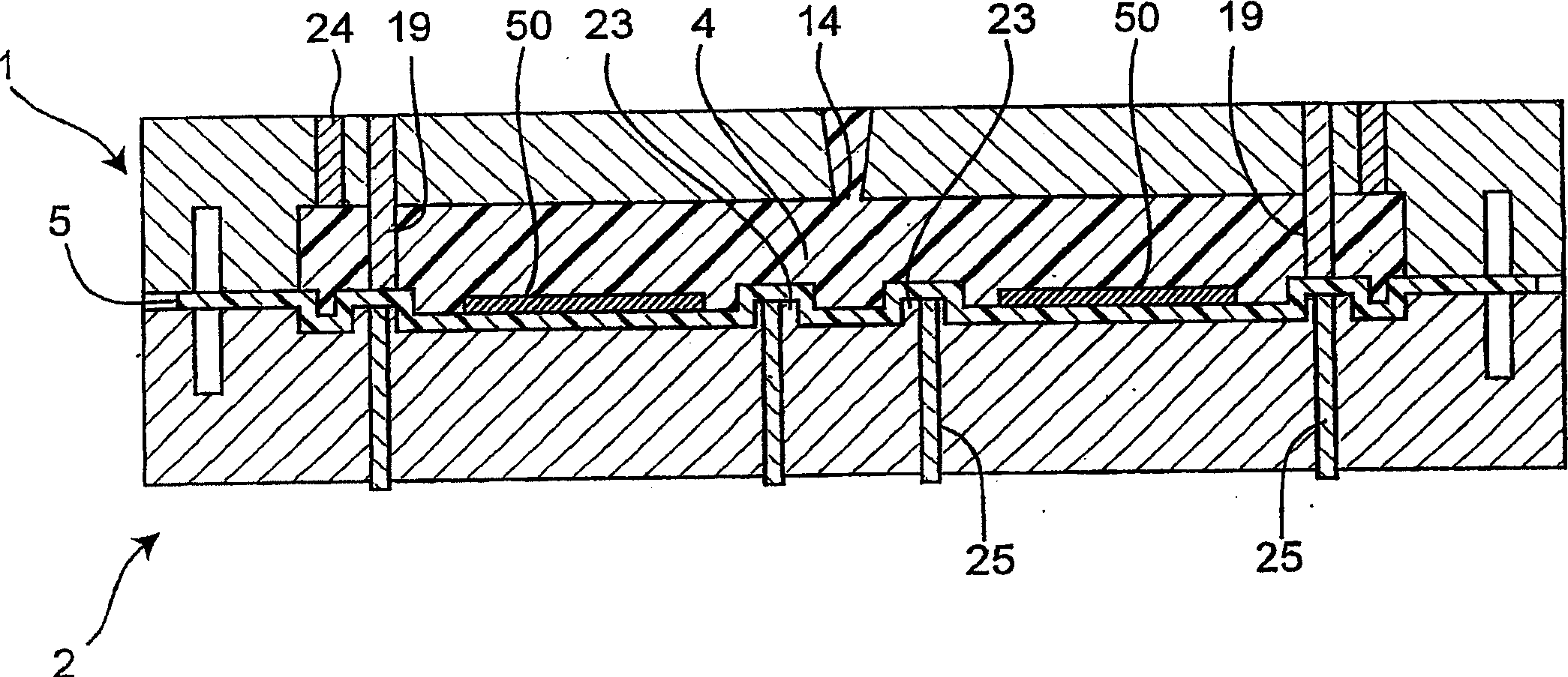

[0163] Next, a first embodiment of the present invention will be described in detail with reference to the drawings. In the drawings used in the description of the respective embodiments of the present invention, the same components are denoted by the same reference numerals.

[0164] First, as a schematic explanatory diagram showing a method of manufacturing an injection-molded simultaneous decorative article according to the first embodiment, figure 1 , figure 2 , image 3 and Figure 4 A schematic sectional view of the first mold and the second mold is shown. In addition, the plan view of this 1st mold is as follows Figure 5 as shown, Figure 6A , Figure 6B , Figure 6C and Figure 6D respectively Figure 5 B-B sectional view, C-C sectional view, D-D sectional view, and E-E sectional view of the first mold. In addition, the top view of the second mold is as follows Figure 7 as shown, Figure 8A and Figure 8B show Figure 7 F-F sectional view and G-G sect...

no. 2 Embodiment approach

[0221] The present invention is not limited to the above-mentioned embodiments, but may also be implemented in other schemes. For example, the injection-molded simultaneous decorative article manufacturing method according to the second embodiment of the present invention can be said to be the same method in terms of using the first mold, the second mold, and the decorative film having substantially the same structure as those in the first embodiment. , but in the point that the first mold and the second mold are placed facing each other with the decorative film set in the middle, and the injection of the molding resin is performed in the state where each mold is opened without clamping the molds, it is different from the above-mentioned first mold. The method of implementation is different. That is, in the second embodiment, the injection of the molding resin is performed in a state where the molding space formed between the first mold and the decorative film is open (that is...

Embodiment 1

[0238] In each of the above-mentioned embodiments, a description has been given in which the molding space 3 is formed by four product molding spaces 31, the molding space 32 for resin injection, and the molding space 33 for resin discharge, but it is not limited thereto. Although there are not only a plurality of product molding spaces but also resin injection molding spaces, various options are conceivable.

[0239] Here, a spatial layout diagram (schematic plan view) of the molding space portion 110 according to the first embodiment is shown in Figure 23 . Such as Figure 23 As shown, the molding space portion 110 is formed by a product molding space portion 111 and a molding space portion 113 for resin discharge. Specifically, the product molding space 111 is a substantially square-shaped space in plan view, and the resin discharge molding space 113 is provided so as to surround the entire outer periphery of the product molding space 111 . In addition, a gate portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com