Compressor base angle

A compressor and bottom angle technology, which is applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve problems such as uneven gaps and increased compressor noise, and achieve the goals of saving materials, avoiding resonance, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

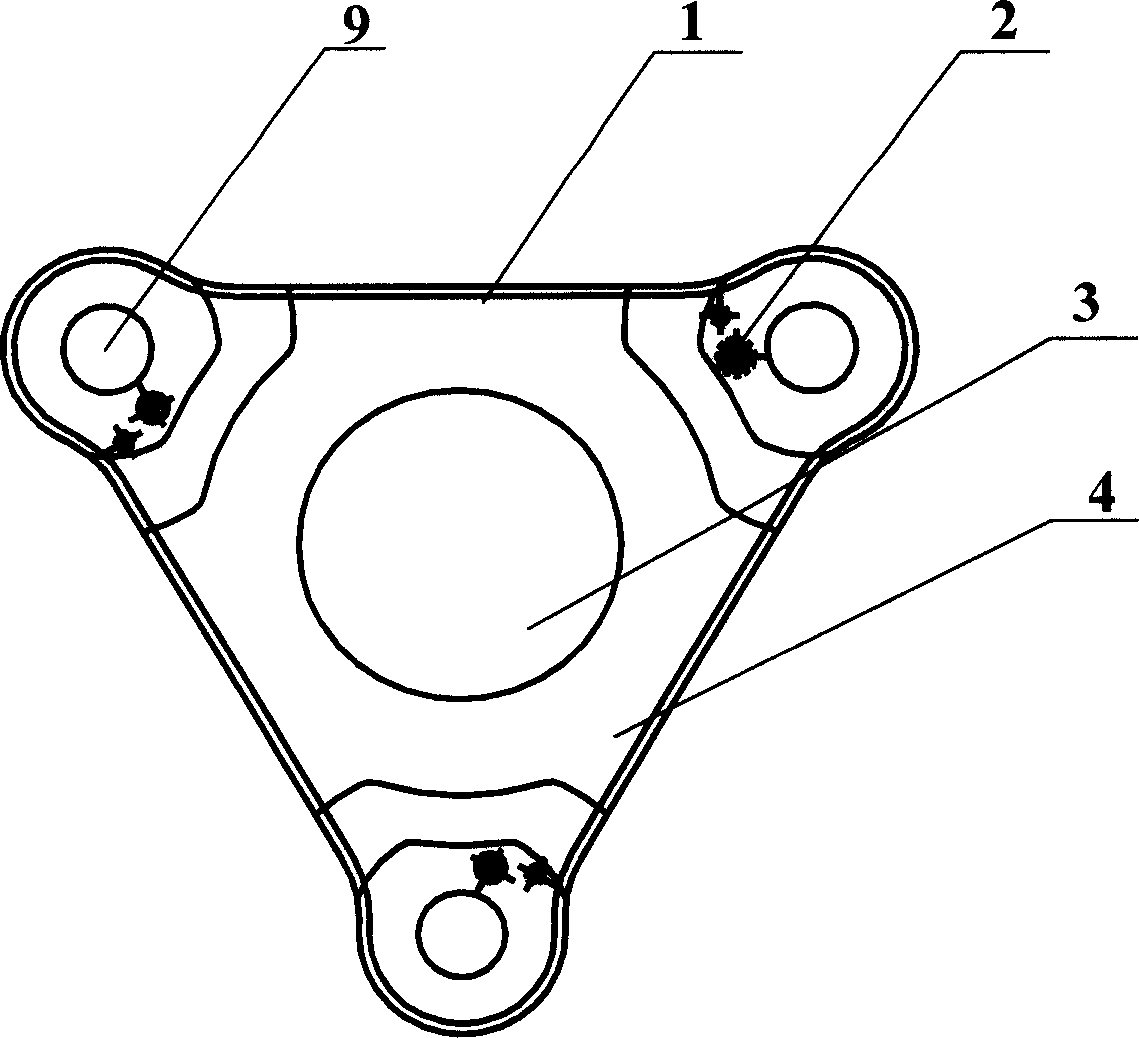

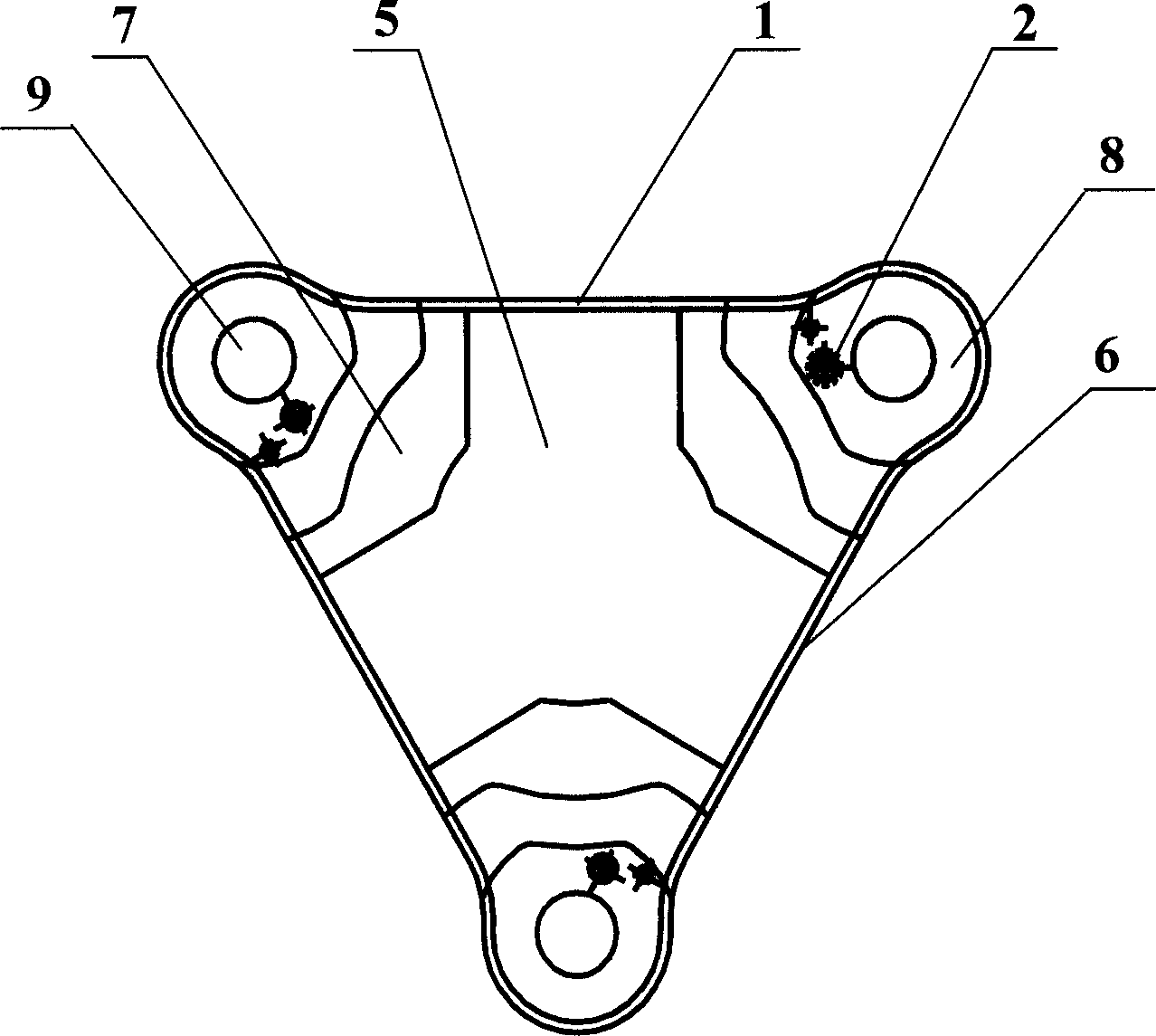

[0017] The bottom angle of the compressor of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 2 As shown, the bottom corner of the compressor includes an edge 6 constituting its edge and a support angle 8 for support at each corner of the bottom corner 1 of the triangle, which is formed in the middle of the bottom corner 1 and around the inner side of the edge 6 There is a hollow portion 5 , and a bottom surface 7 is formed between the hollow portion 5 and each support angle 8 . The three support angles 8 are formed by inclining from the bottom surface 7 for a section and then extending horizontally outward. A round hole 9 is formed in the center of each top angle 8, and the round hole 9 is used for installing a shock absorber supporting the compressor.

[0019] The edge 6 on the corner 1 forms the three sides of the corner 1 .

[0020] When assembling the compressor, place the bottom cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com