Digital control electric chuck for lathe

An electric chuck, lathe technology, applied in the direction of chucks, turning equipment, tool holder accessories, etc., can solve the problems of inconvenient use, troublesome adjustment of the center of the four-jaw chuck, and the chuck cannot be used universally, and achieves accurate action, Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

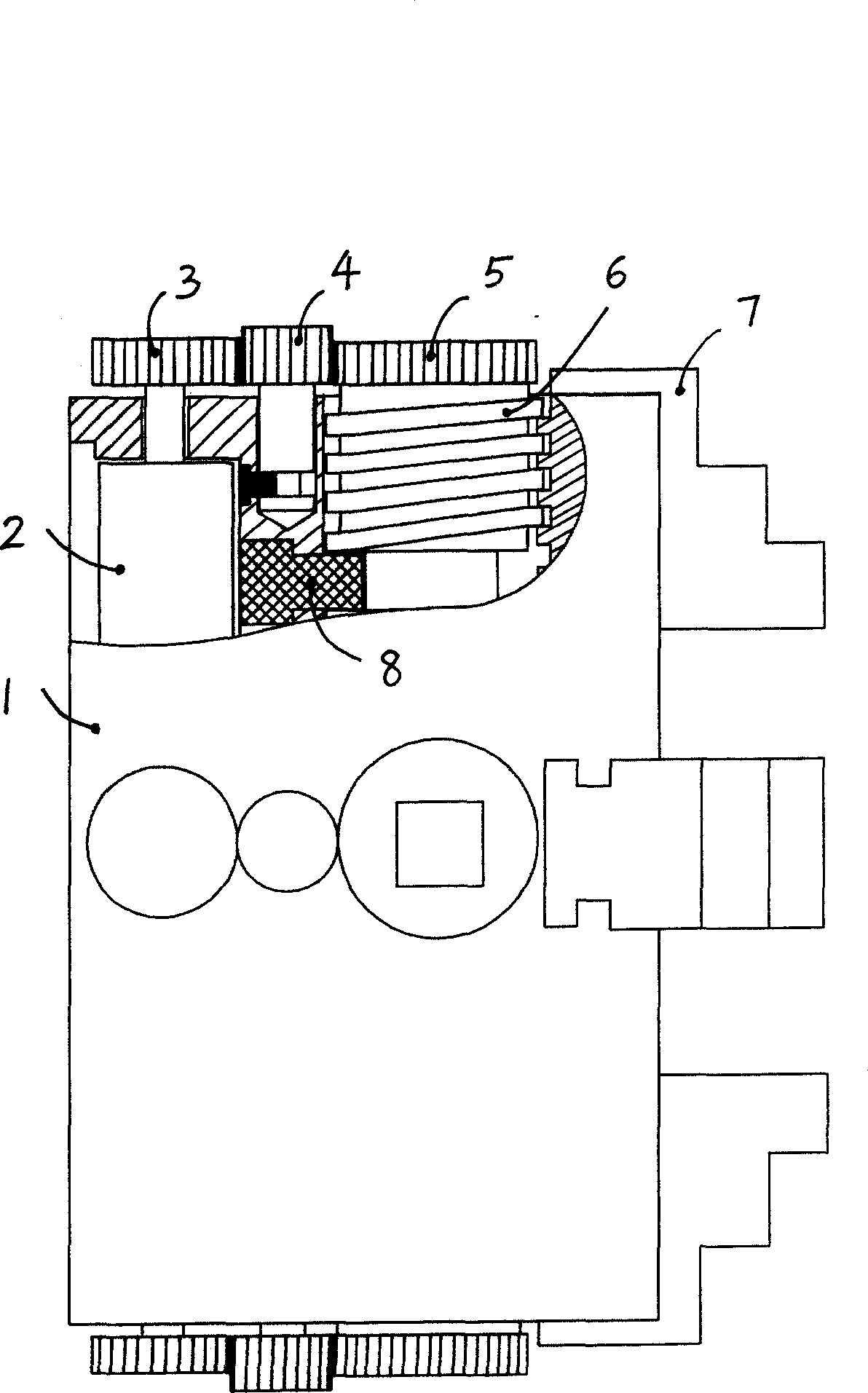

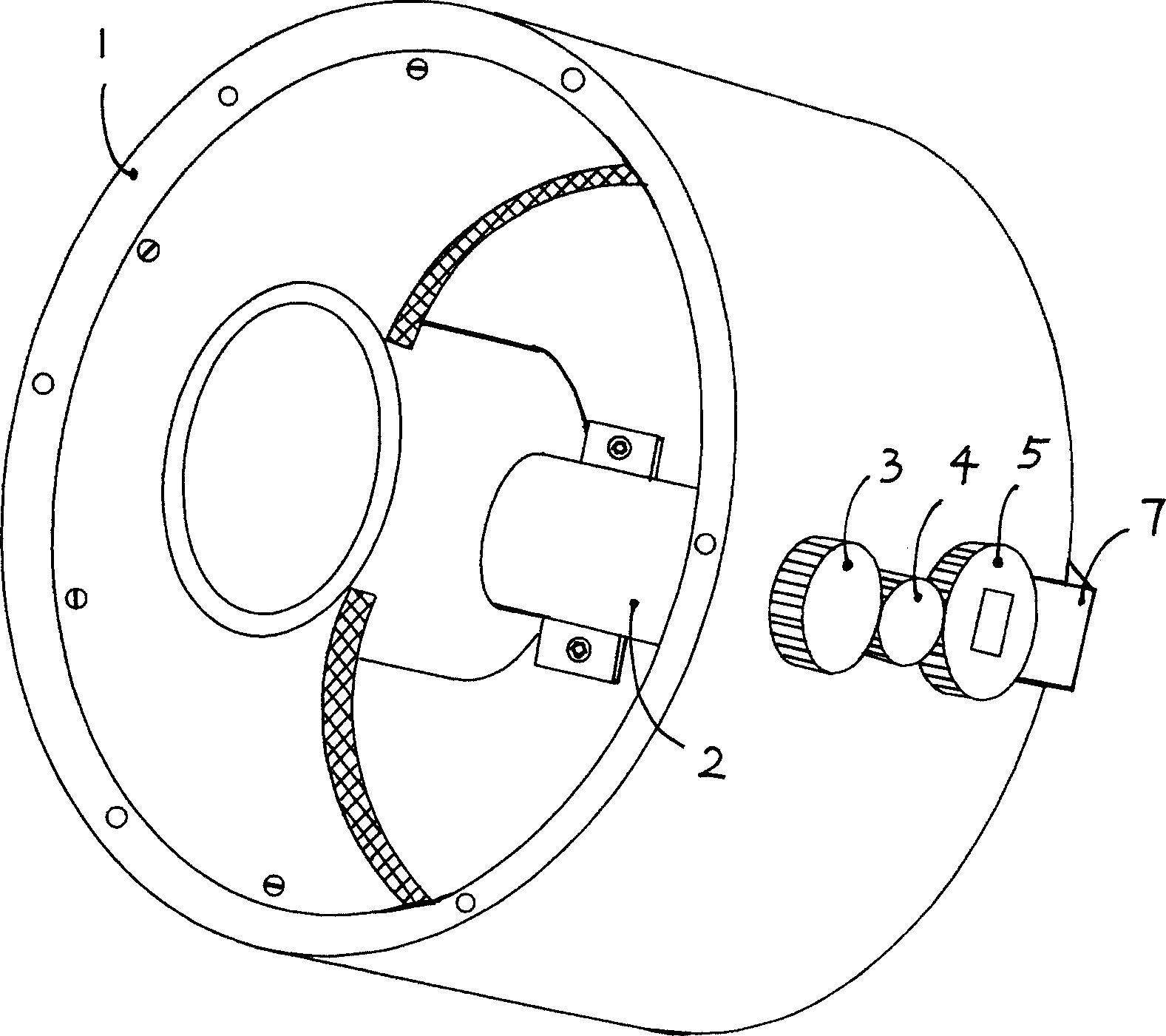

[0014] combine figure 1 with figure 2 , the lathe numerical control electric chuck of embodiment, comprise chuck body 1, the claw 7 that is installed one by one by four claw chute of chuck body, the back of claw 7 is shaped on screw tooth, the claw on the chuck body Four screw rods 6 are respectively arranged at the corresponding positions of the rear part, and the screw rods 6 are engaged with the claws 7 one by one, and these structures are the same as those of the existing four-jaw chuck.

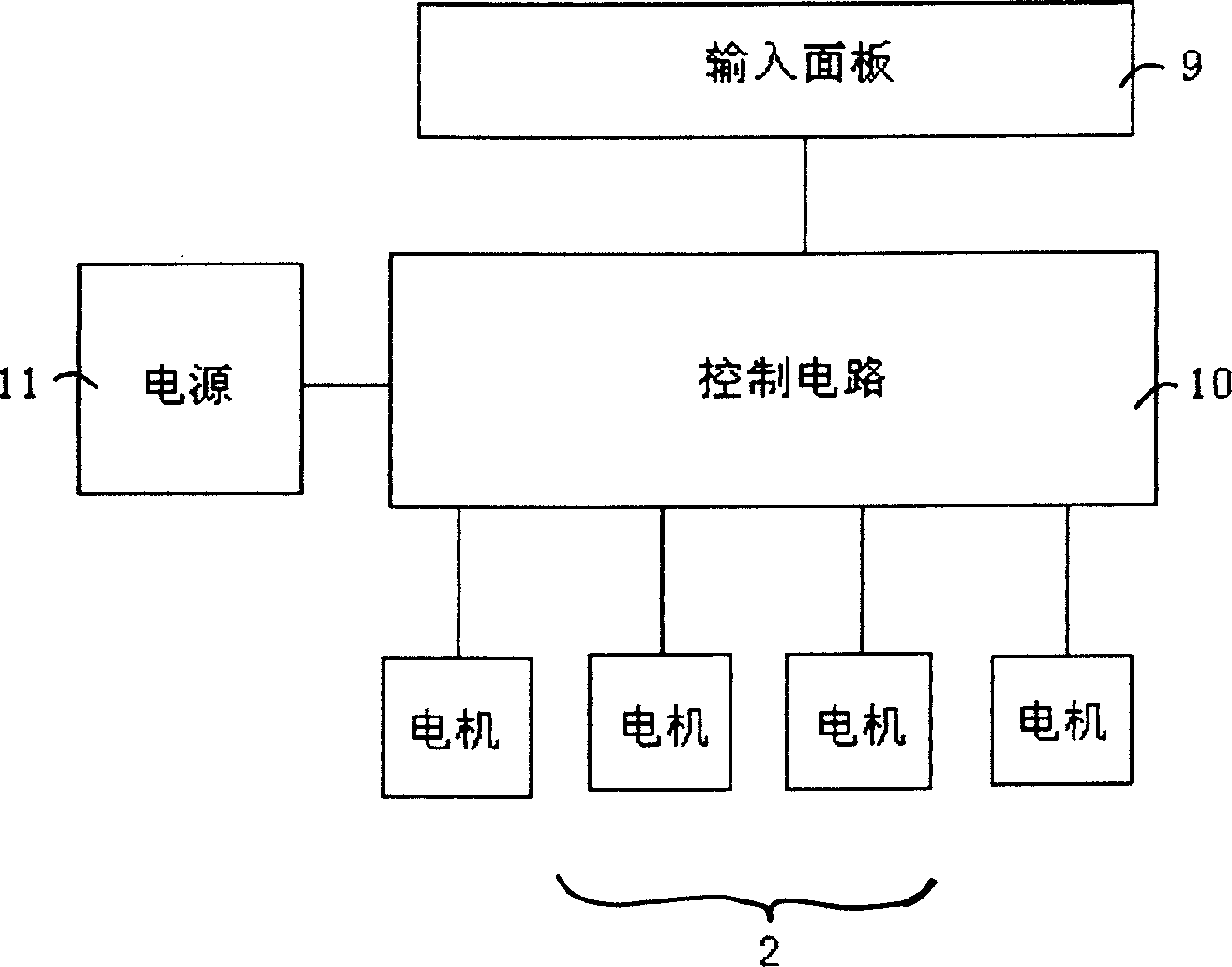

[0015] The screw rod 6 is provided with a driven gear 5, and in the chuck body, four motors 2 are respectively arranged at the corresponding positions of the rear part of the screw rod 6, and the driving gear 3 is fixed on the motor shaft, between the driving gear 3 and the driven gear 5. An intermediate gear 4 is also provided, and the driving gear 3 and the driven gear 5 are engaged and connected through the intermediate gear 4 .

[0016] During installation, the control device comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com