Connection branch pipe

A technology for connecting branch pipes and branch pipes, which can be used in branch pipelines, pipes, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

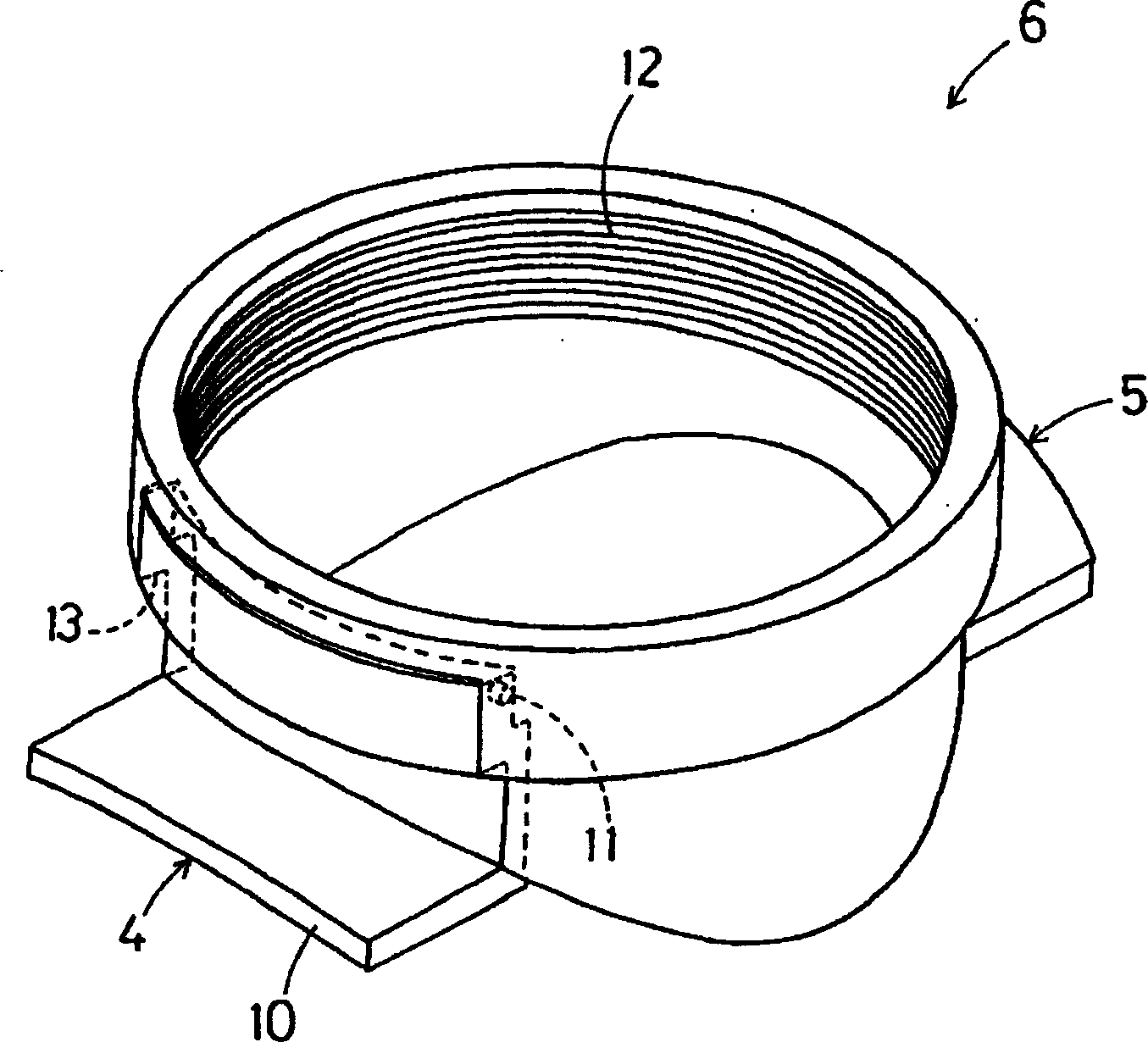

[0044] according to Figure 1 to Figure 6 The illustrated embodiments illustrate the invention in detail.

[0045] In this embodiment, the case where the connection branch pipe 1 is used to connect the installation pipe (not shown) which is the branch pipe connected to the common tank of each household to the sewage main pipe 2 which is the main pipe is exemplified.

[0046] The connecting branch pipe 1 has: a locking part 6 provided with two locking claws 4 and 5 which lock the periphery of the opening part 3 of the sewer main pipe 2; 7; and a connecting part 9 inserted into the saddle part 7 and provided with a rubber ring socket 8 as a connecting port for connecting the installation pipe at the upper part.

[0047] Such as figure 1 and figure 2 As shown, the cross-section of the two locking claws 4 and 5 of the locking member 6 is approximately L-shaped, and the shape of the locking plate 10 protruding substantially horizontally is a shape along the inner peripheral sur...

Embodiment 2

[0073] Figure 7 ~ Figure 12 represents another embodiment.

[0074] The connecting branch pipe 1 of this embodiment has: a locking part 6 provided with two locking claws 4 and 5 that are locked on the periphery of the opening part 3 of the sewer main pipe 2; The saddle part 7 above the sewer main pipe 2; and the connecting part 9 inserted in the saddle part 7 and provided with a rubber ring socket 8 as a connection port for connecting the installation pipe at the top.

[0075] Such as Figure 7 As shown, the cross section of the two locking claws 4 and 5 of the locking member 6 is roughly L-shaped, and the shape of the locking plate 10 protruding substantially horizontally is a shape along the inner peripheral surface of the opening 3 of the sewer main pipe 2. bow shape.

[0076] A pair of pivot pins 11 protrude from the side of the central part of one locking claw 4 , and the one locking claw 4 is rotatably pivoted to the locking member 6 through the pivot pins 11 . In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com