Cartridge and image forming apparatus

A technology for imaging equipment and process cartridges, applied in the fields of process cartridges and imaging devices, can solve problems such as the inability to prevent toner leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] example

[0038] will refer to Figures 1 to 12 Some aspects of the invention are described.

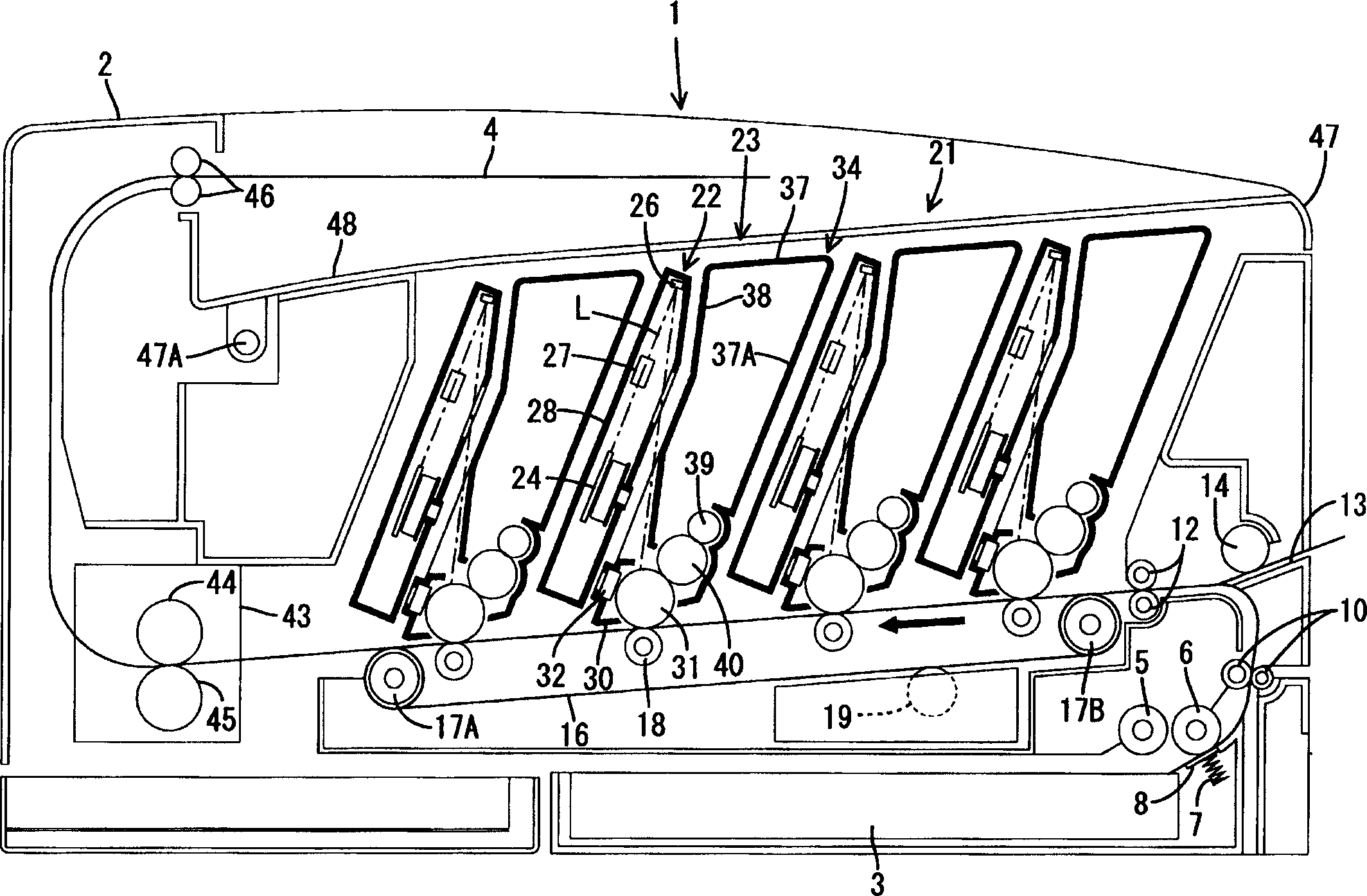

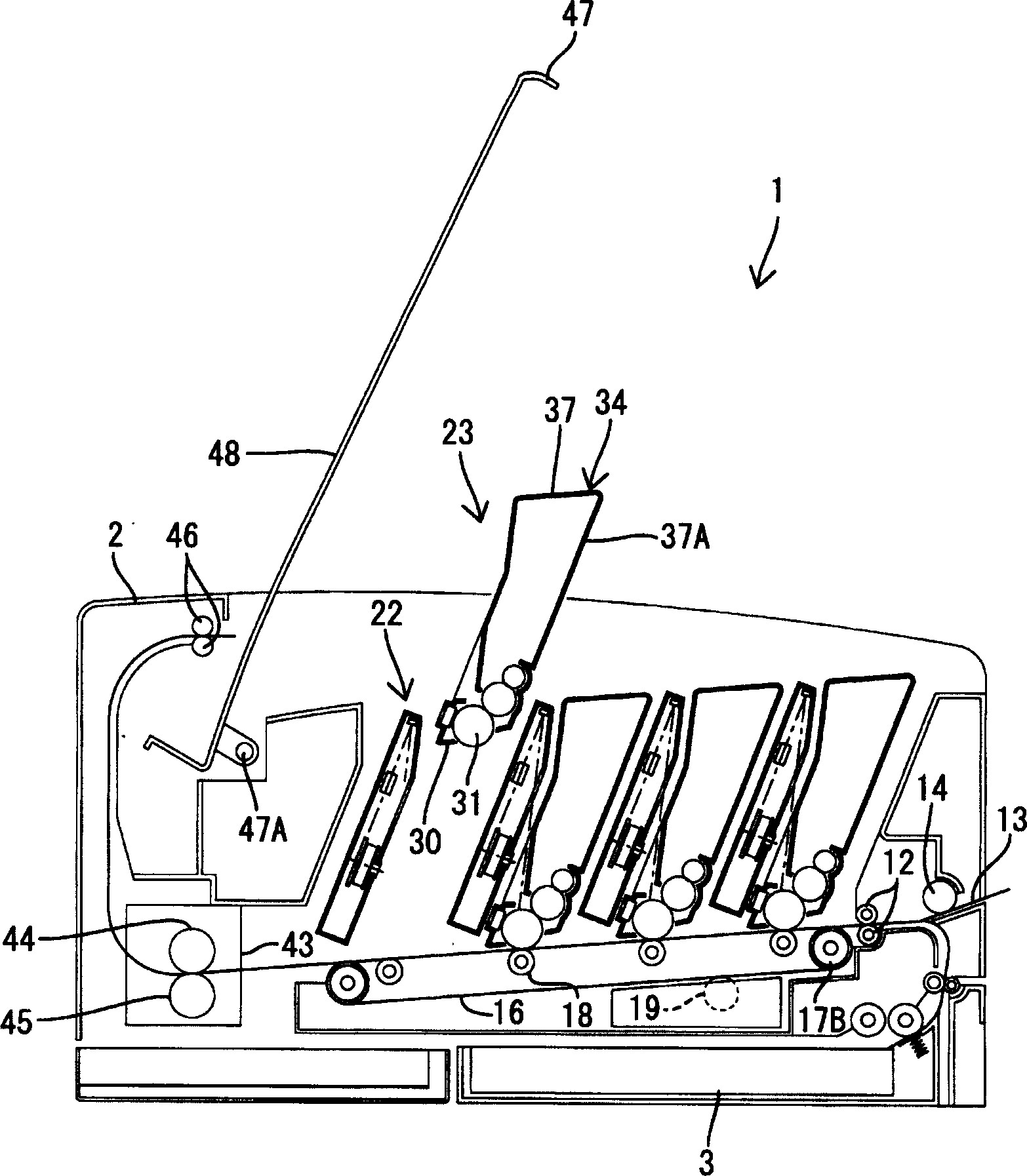

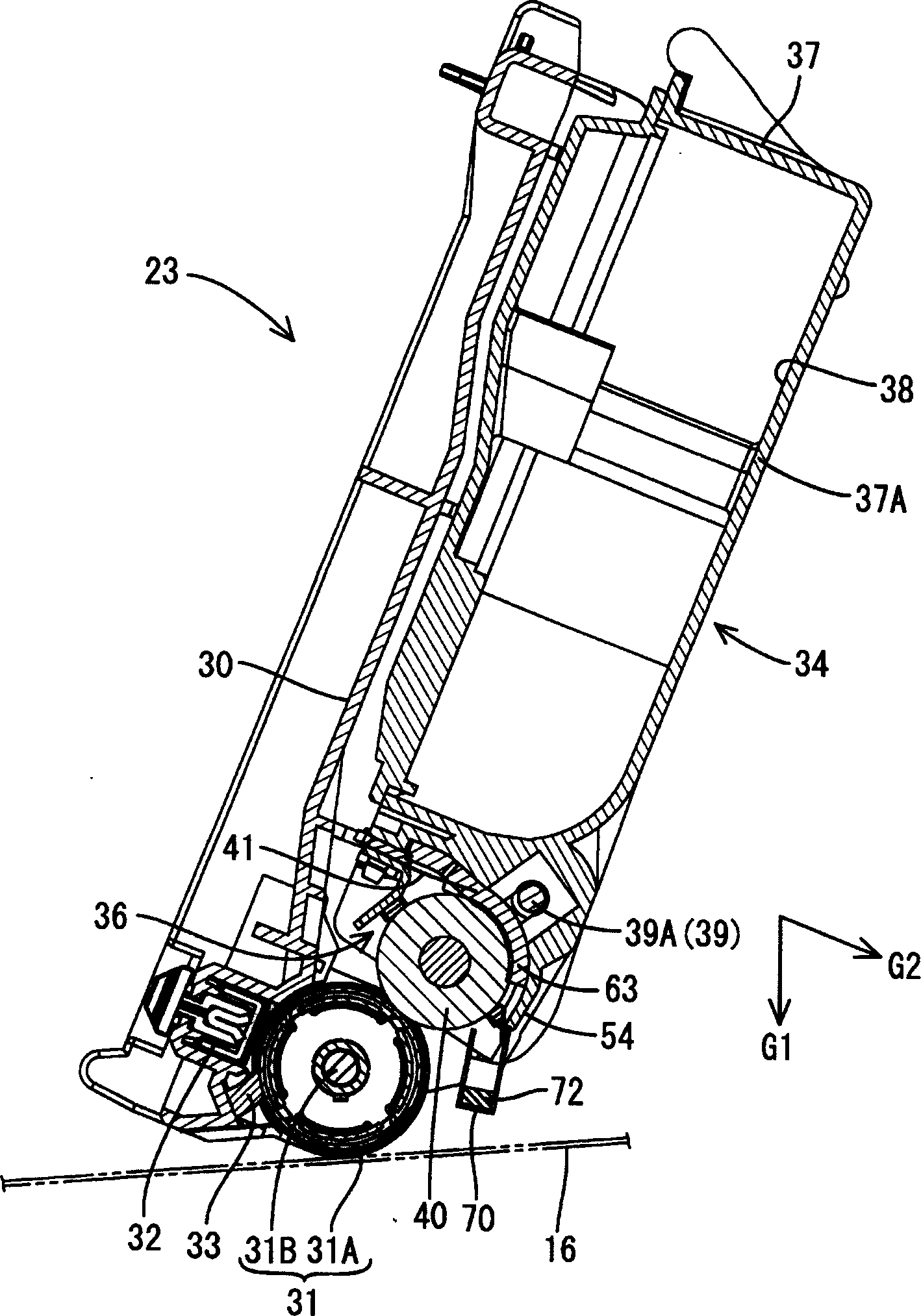

[0039] figure 1 is a side sectional view of the overall structure of a laser printer 1 as an image forming apparatus according to aspects of the present invention. The laser printer 1 is a direct tandem color laser printer having four photosensitive drums 31 corresponding to black, cyan, magenta, and yellow, respectively. In the description below, figure 1 The right side in is called the front side.

[0040] The laser printer 1 includes a lower paper feed tray 3 inside a main body case 2 . A paper feed tray 3 is detachably attached to the main body case 2 from the front side. The paper feed tray 3 is configured to supply a stack of paper 4 for image formation. A platen (not shown) is provided at the bottom of the paper feed tray 3 and is configured to lift the leading end of the paper 4 . The pick-up roller 5 and the paper supply roller 6 arranged in series, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com