Production method of film laminates and production apparatus used therein

A manufacturing method and a manufacturing device technology, which are applied in the field of optical thin films and image display devices, can solve the problems of reduced attractiveness, complex structure, cumbersome operation, etc., and achieve the effect of improving attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

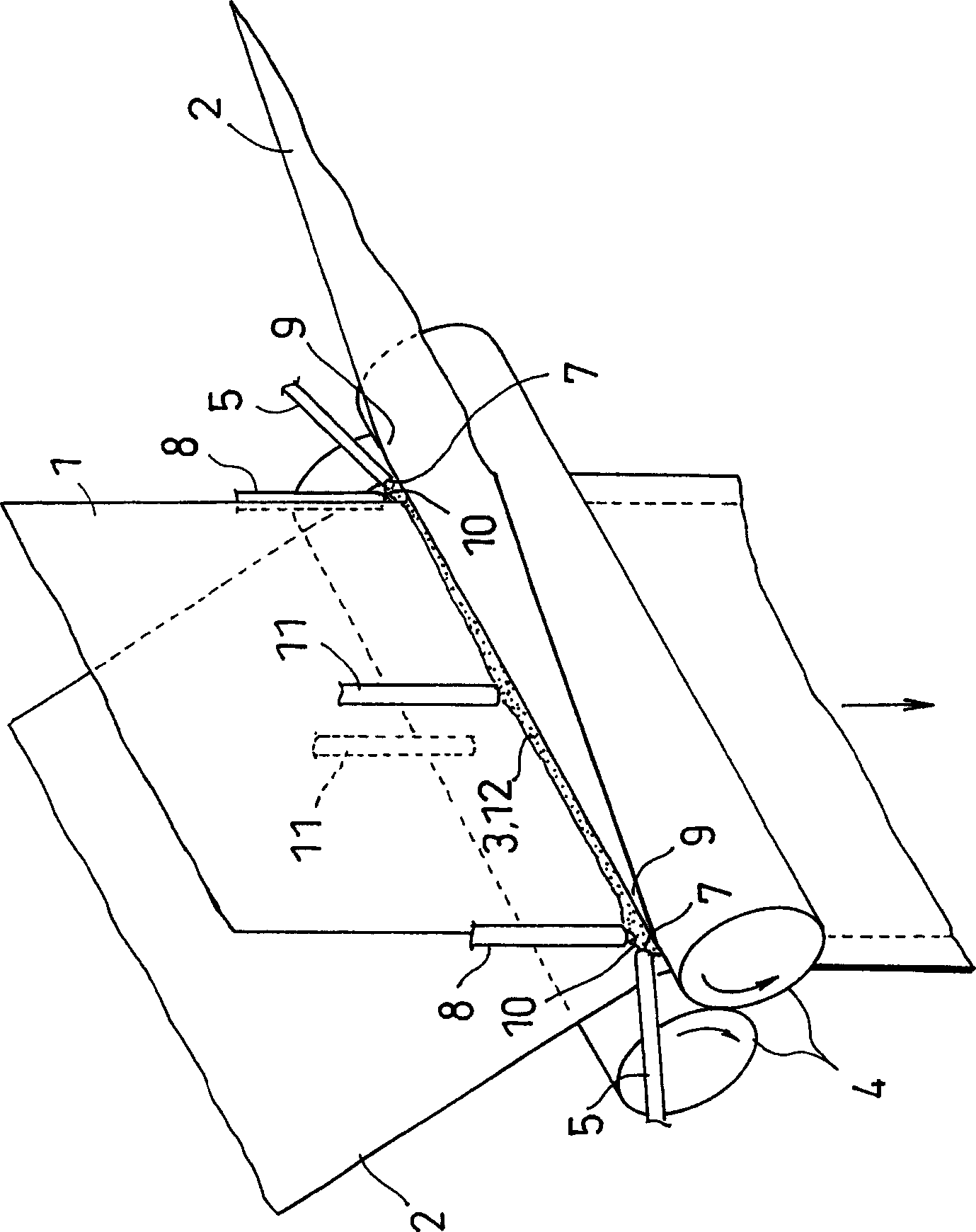

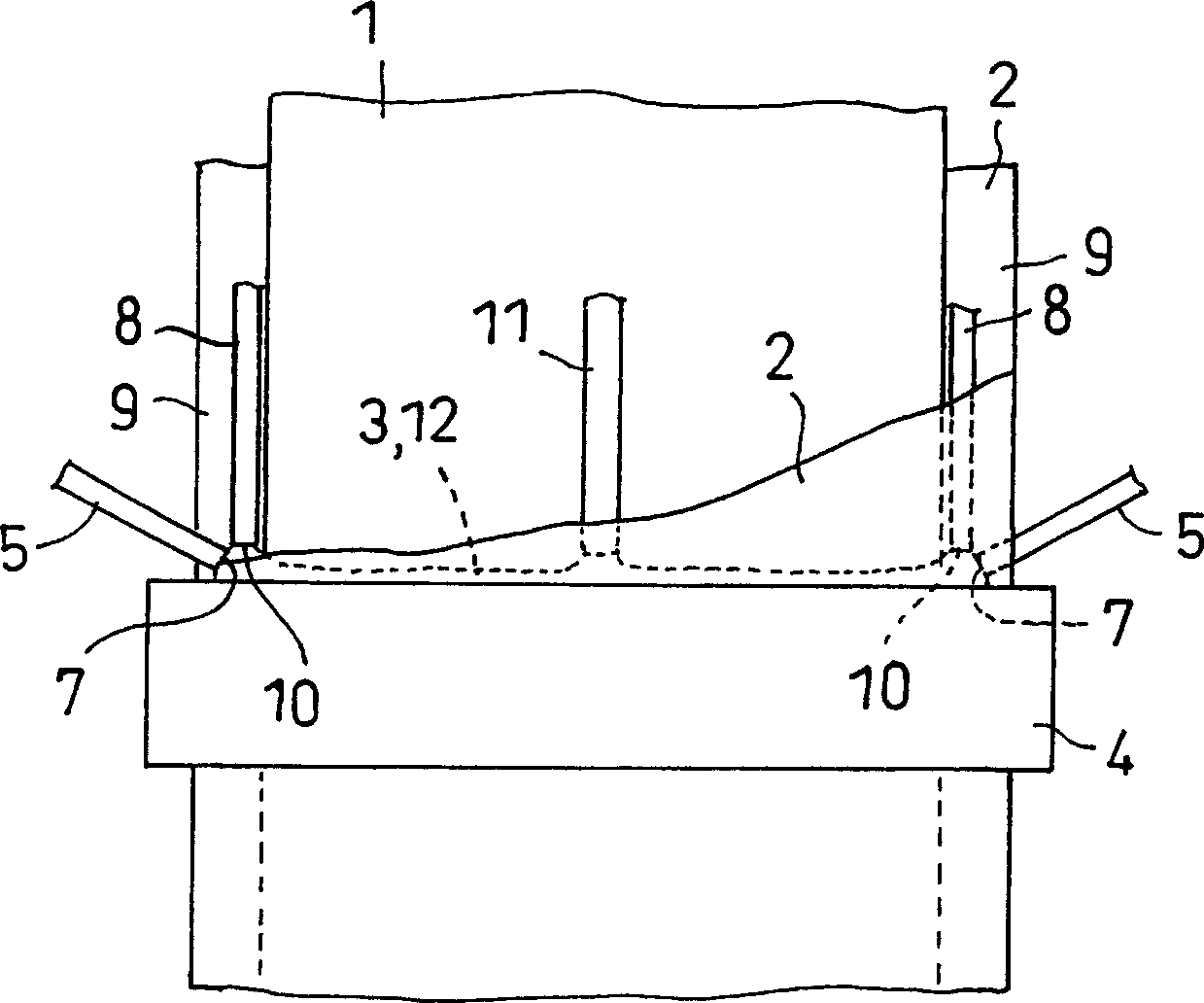

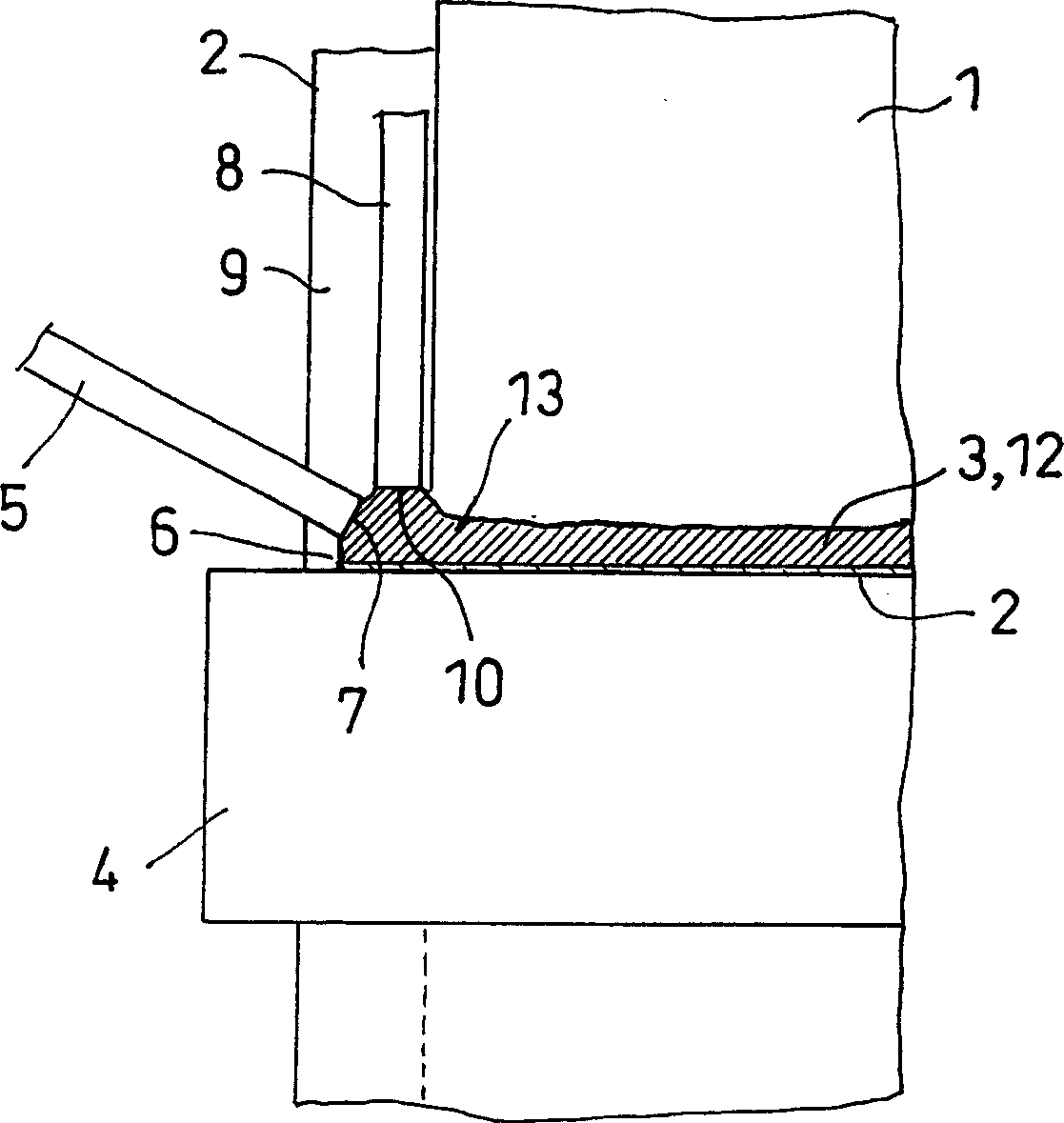

[0055] Refer to the side below Figure 1 to Figure 5 , one embodiment of the present invention will be described. However, parts that are not necessary for the description are omitted, and there are also parts that are shown enlarged or reduced in order to facilitate the description.

[0056] First, the method for producing the film laminate in the present invention will be described below using a polarizing plate as an example. figure 1 It is a perspective view for demonstrating the manufacturing method of the polarizing plate in embodiment of this invention. figure 2 It is a side view for demonstrating the manufacturing method of the said polarizing plate. image 3 is to zoom in figure 2 An enlarged view of the main part of . Figure 4 It is a schematic diagram showing the shape of the opening portion of the suction port in the suction nozzle in the above-mentioned manufacturing apparatus of the polarizing plate. Figure 5 It is a cross-sectional schematic view schema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com