Electric spanner

An electric wrench and wrench body technology, applied in the field of electric wrenches, can solve the problems of inaccurate adjustment, loose jaws, screwed nuts, etc., and achieve the effects of not tight jaws, simple structure, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

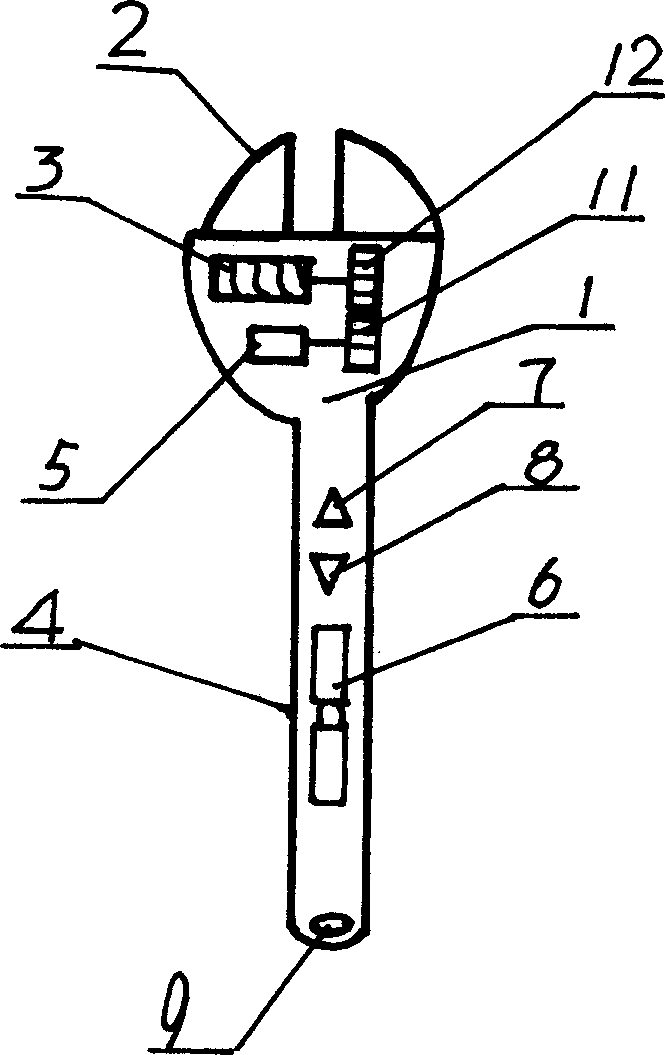

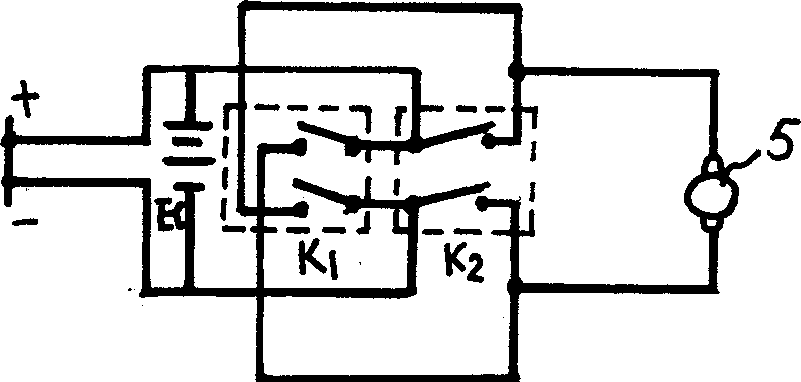

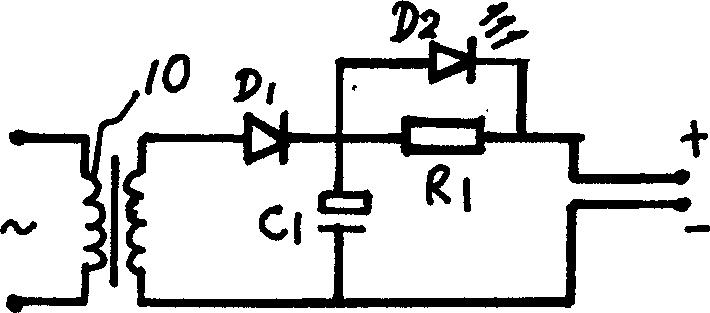

[0010] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, the present invention is made up of wrench body 1, tiger's mouth 2, adjustment nut 3 and handle 4 by the wrench, the wrench body 1 below wrench adjustment nut 3 is provided with deceleration motor 5, handle 4 The rechargeable battery 6, the charging circuit, the control circuit and the charging socket 9 provided at the end of the handle 4 are formed in the cavity; the gear 11 connected to the shaft end of the reduction motor 5 meshes with the gear 12 connected to the adjustment nut; the rechargeable battery 6 is composed of two Section 7 rechargeable battery, charged by the set charging circuit, the charging circuit is composed of transformer 10, diode D1, capacitor C1 and resistor R1, diode D1, capacitor C1 constitute a half-wave rectifier filter circuit, resistor R1 is used for current limiting, diode D2 is a light-emitting diode for indication; the rechargeable battery 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com