Button cell

A button battery and battery casing technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of reducing the negative electrode casing, reducing the sealing performance, and reducing the battery capacity, so as to prevent leakage and prevent battery capacity. The effect of reducing and inhibiting plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

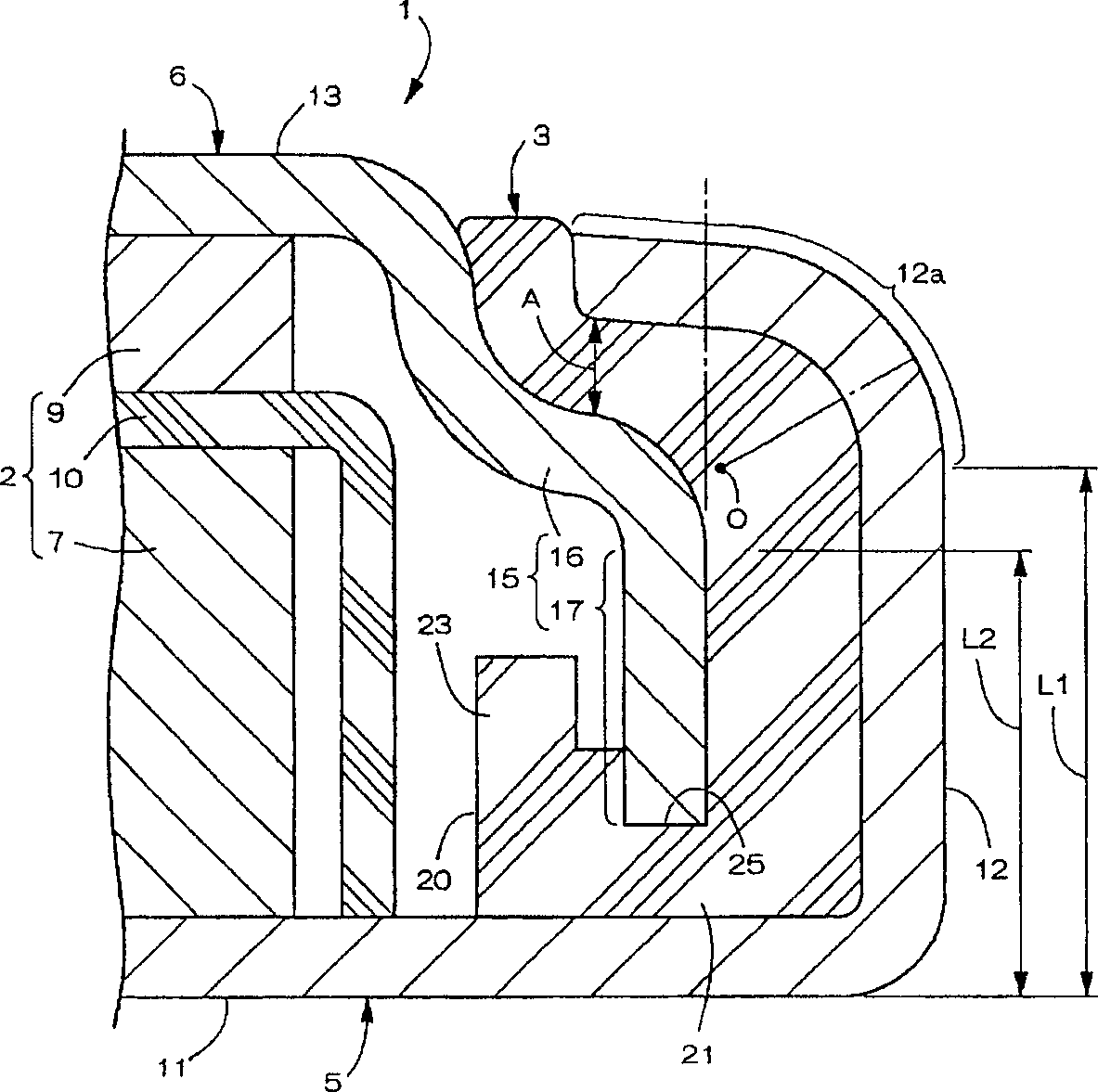

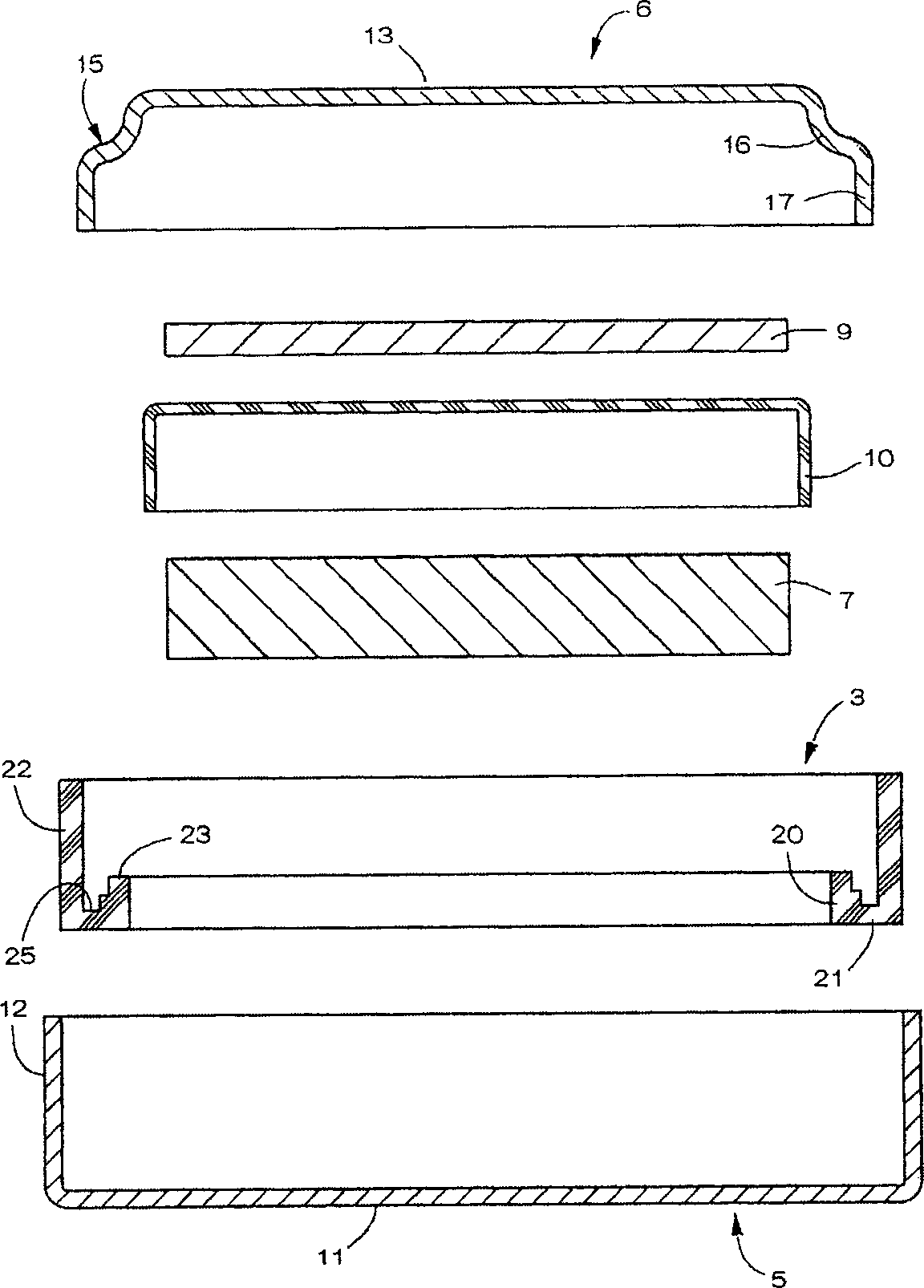

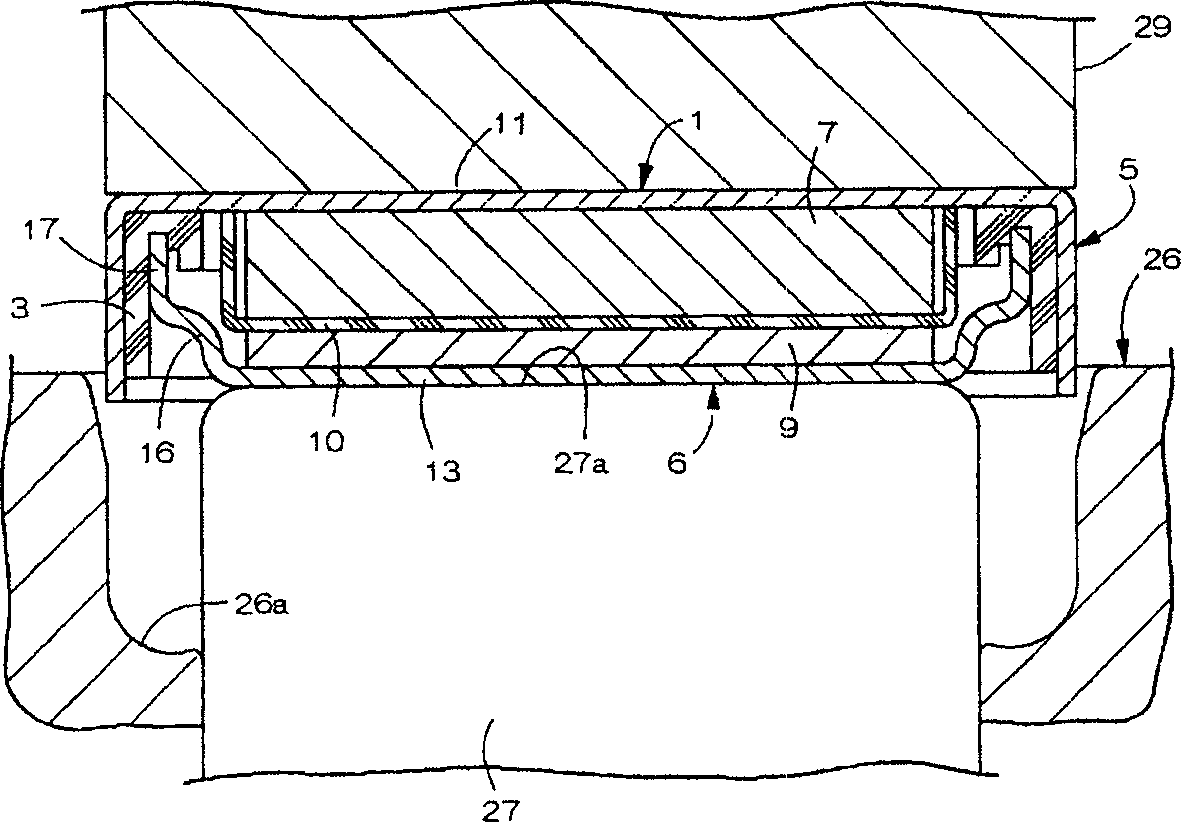

[0031] figure 1 and figure 2 Example 1 showing a button-type battery as the object of the present invention, such as figure 1 As shown, the battery case 1 has: a power generating element 2 accommodated in the battery case 1, a sealing gasket 3 sealed inside the battery case 1, and a positive electrode case 5, which are fastened and fixed on the inner edge of the opening of the positive electrode case 5 through the sealing gasket 3 The negative electrode casing 6 is formed into a flat button shape as a whole. Incidentally, the outer diameter dimension of the battery case 1 is 12 mm, and the upper and lower thickness dimensions are 2 mm.

[0032] The power generating element 2 includes a positive electrode material 7 and a negative electrode material 9 solidified in a disk shape, and a separator 10 installed therebetween. The main component of the positive electrode material 7 is manganese dioxide, and the negative electrode material 9 is composed of metal lithium. The sepa...

Embodiment 2

[0044] In Example 2, the radius of curvature of the curved portion 12 a of the outer peripheral cylindrical wall 12 of the positive electrode case 5 was set to 0.8 mm. The direction A in which the sealing gasket 3 is most compressed is inclined at 84 degrees with respect to the bottom wall 11 of the positive electrode case 5 . Since the others are the same as those in Embodiment 1, description thereof will be omitted.

Embodiment 3

[0046] In Example 3, the inward front end of the curved portion 12 a of the outer peripheral cylindrical wall 12 of the positive electrode case 5 is closer to the outside of the battery than the inner peripheral surface of the straight portion 17 of the negative electrode case 6 . Since other points are the same as in Embodiment 1, description thereof will be omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com