Thread feeding speed stabilizing device and method for double twister roller

A wire feeding and speed technology, applied in textiles and papermaking, etc., can solve the problems of unstable winding speed, strand slippage, twist unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

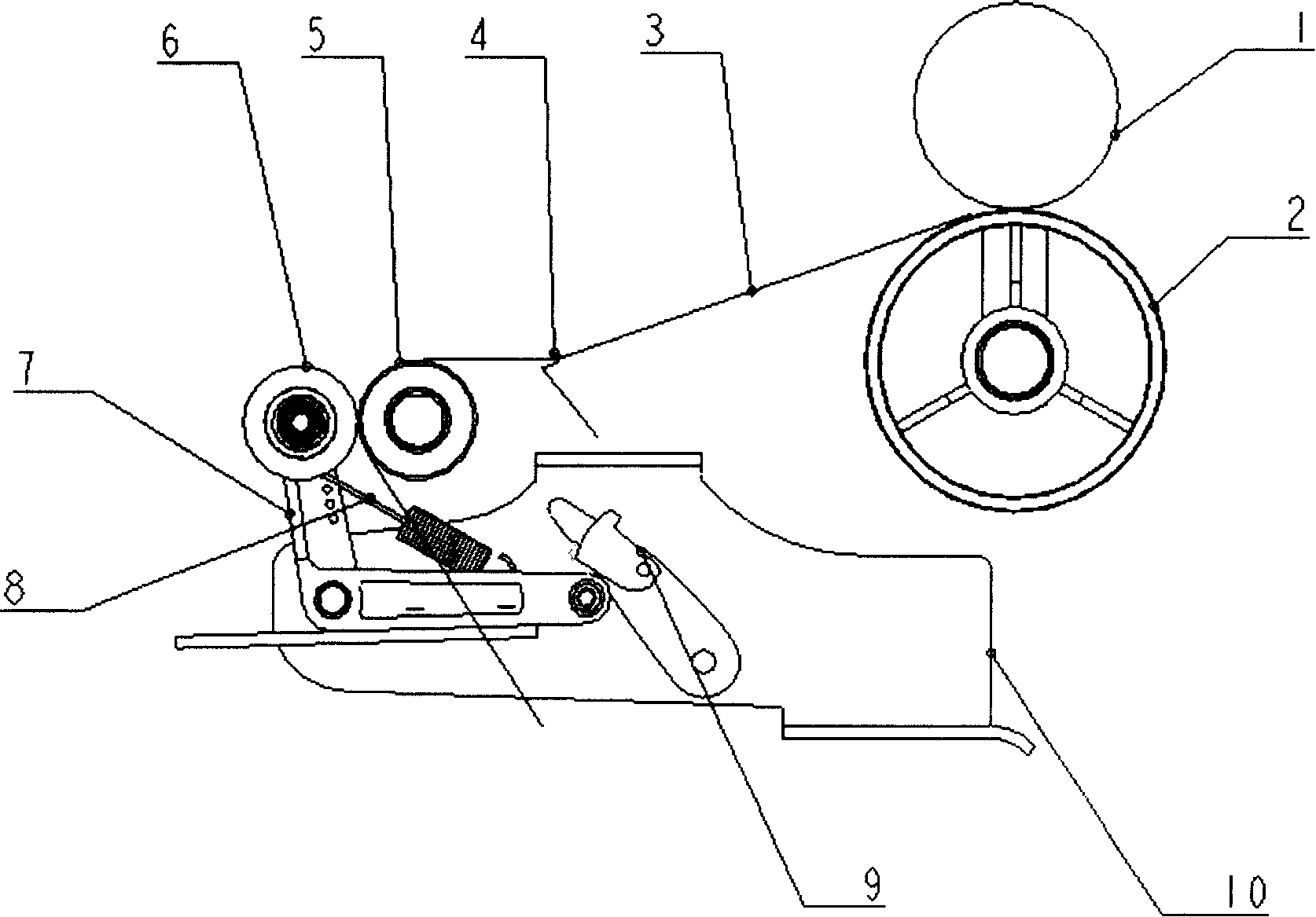

[0008] As shown in the figure, it is a device and method for controlling the constant wire feeding speed of two-for-one twister rollers. The strand 3 passes through the clamping point of the upper roller 6 and the lower roller 5, wherein the lower roller 5 is the driving wheel, and the wire feeding speed of the roller is controlled by the lower roller. The diameter and rotating speed of the roller are controlled, and the clamping force between the upper roller 6 and the lower roller 5 is pulled by the extension spring 8; Wherein top roller 6 and extension spring 8, roller support 7, rocking arm 9 are installed on the mounting plate 10 by conventional connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com