C5íóC9 copolymerized petroleum resin preparation method

A technology for copolymerizing petroleum resin and polymerization liquid, which is applied in the field of preparation of C5, C9 copolymerized petroleum resin, and can solve the problems of less copolymerization and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

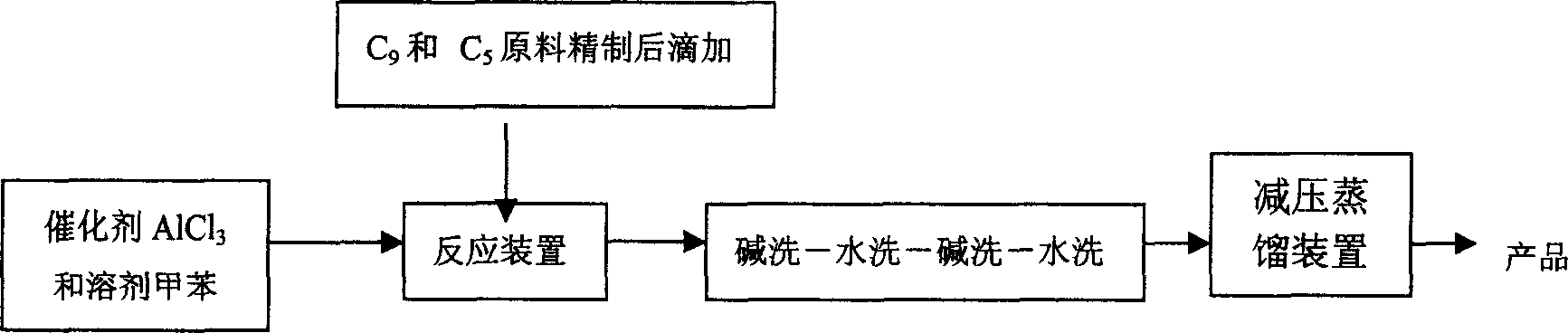

Method used

Image

Examples

Embodiment 1

[0037] Collect C with a boiling point of 40-70°C under normal pressure 5 Alkenes and C with a boiling point of 90-120°C at a vacuum of 0.09 MPa 9 Olefin component; first in the reactor with stirring (stirrer model is 60W, 3000 rpm, Changzhou Guohua Electric Machinery Co.), adding mass percentage is 10% toluene as solvent under the condition of being lower than 10 ℃ , then add 2% AlCl 3 Catalyst; Then in the toluene solvent with the speed of 2 drops / second dripping the C9 that the mass percentage is 30%, then with the speed of 1 drop / second in the toluene solvent, drop the C5 that the mass percentage is 60%; Dropping is completed After that, stir evenly, and react at 60°C for 6 hours to obtain a polymerization solution; pour the reacted polymerization solution into a separatory funnel and perform water washing-alkali washing-water washing at 75°C. It is a 5% NaOH solution, and this process is carried out alternately until the polymerization liquid is washed to neutral; pour t...

Embodiment 2

[0039] Collect C with a boiling point of 40-70°C under normal pressure 5 Alkenes and C with a boiling point of 90-120°C at a vacuum of 0.09 MPa 9 Olefin component; first in a stirred reactor, add 8% by mass of toluene as a solvent at a temperature lower than 10°C, and then add 1% by mass of AlCl 3 Catalyst; Then in the toluene solvent with the speed of 2 drops / second dripping mass percent is after the C9 of 33%, then in the toluene solvent with the speed of 1 drop / second is the C5 that drips the mass percent of 66%; Drops complete Afterwards, stir evenly, and react at 50°C for 5 hours to obtain a polymerization liquid; pour the reacted polymerization liquid into a separatory funnel and perform water washing-alkali washing-water washing at 65-75°C, and this process is carried out alternately until the polymerization liquid Washed to neutral; pour the polymer solution washed to neutral into the reactor, heat and distill the polymerization solution at 0.08Mpa, the heating temper...

Embodiment 3

[0041] Collect C with a boiling point of 40-70°C under normal pressure 5 Alkenes and C with a boiling point of 90-120°C at a vacuum of 0.09 MPa 9 Olefin component; first in a stirred reactor, add 9% by mass of toluene as a solvent at a temperature lower than 10°C, and then add 0.5% by mass of AlCl 3 Catalyst; Then in the toluene solvent with the speed of 2 drops / second dripping mass percent is after the C9 of 16%, then in the toluene solvent with the speed of 1 drop / second drips the C5 that the mass percent is 74.5%; Dropping is finished Afterwards, stir evenly, and react at 40°C for 3 hours to obtain a polymerization solution; pour the reacted polymerization solution into a separatory funnel and perform water washing-alkaline washing-water washing at 65°C, and this process is carried out alternately until the polymerization solution is washed to neutrality; pour the neutralized polymerization solution into the reactor, heat and distill the polymerization solution at 0.09Mpa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com