Globular catalyst component used for olefine polymerization and its catalyst

A technology of olefin polymerization and catalyst, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc. It can solve the problems of large magnesium chloride alcoholate particles, unsatisfactory catalyst activity, Wide particle size distribution etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Preparation of magnesium chloride / alcohol adduct particles

[0058] Take the following steps:

[0059] (1), the preparation of magnesium chloride / alcohol adduct melt: in the 150L reactor with stirring, 10kg anhydrous magnesium chloride and 12.6kg ethanol are added in the white oil that 60L viscosity is 30 centipoise (20 ℃), in The reaction was carried out at 125°C for 2 hours. Then transfer the mixture of molten adduct and white oil to the medium of methyl silicone oil which has been preheated to 125°C; the viscosity of the methyl silicone oil is 300 centipoise (20°C), and the amount of methyl silicone oil is 120L ; Stir at a speed of 200 rpm for 10 to 30 minutes.

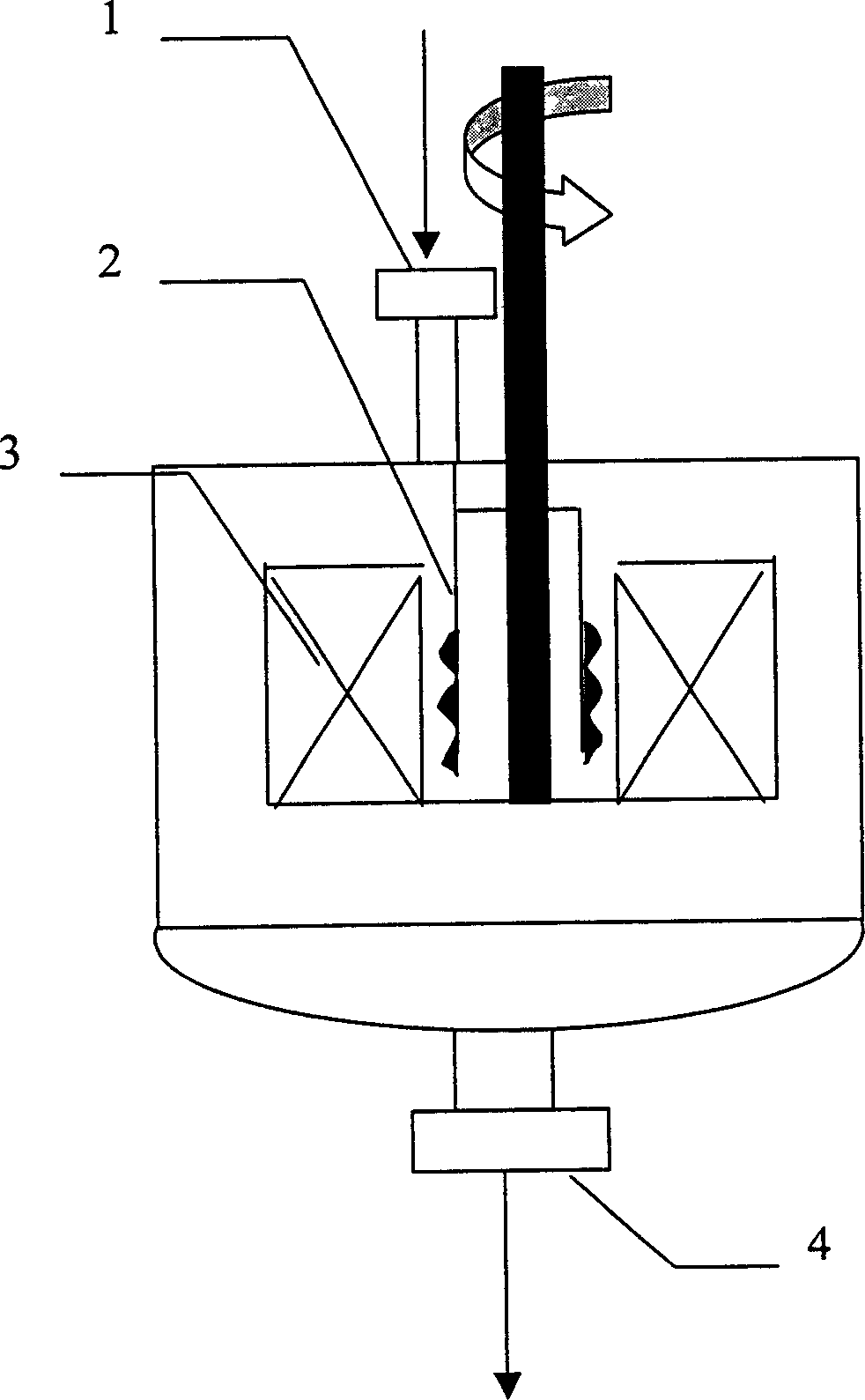

[0060] (2) Dispersion: the above-mentioned mixed solution enters the high-gravity rotating bed from the feed port 1 (as attached figure 1 shown), through the static liquid distributor 2 arranged at the center of the rotor, it is evenly sprayed on the inner edge of the high-speed rotating pac...

Embodiment 2

[0064] Embodiment 2: The operation is the same as in Embodiment 1, except that the rotating speed of the supergravity rotating bed is adjusted to 1200 rpm. The results are shown in Table 1.

Embodiment 3

[0065] Embodiment 3: The operation is the same as in Embodiment 1, except that the rotating speed of the high-gravity rotating bed is adjusted to 2000 rpm. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com