Focusing control method for optical disc

A focus control, optical disc technology, applied in the direction of optical recording/reproduction, optical recording head, beam guiding device, etc., can solve the problem that the optical head is not optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

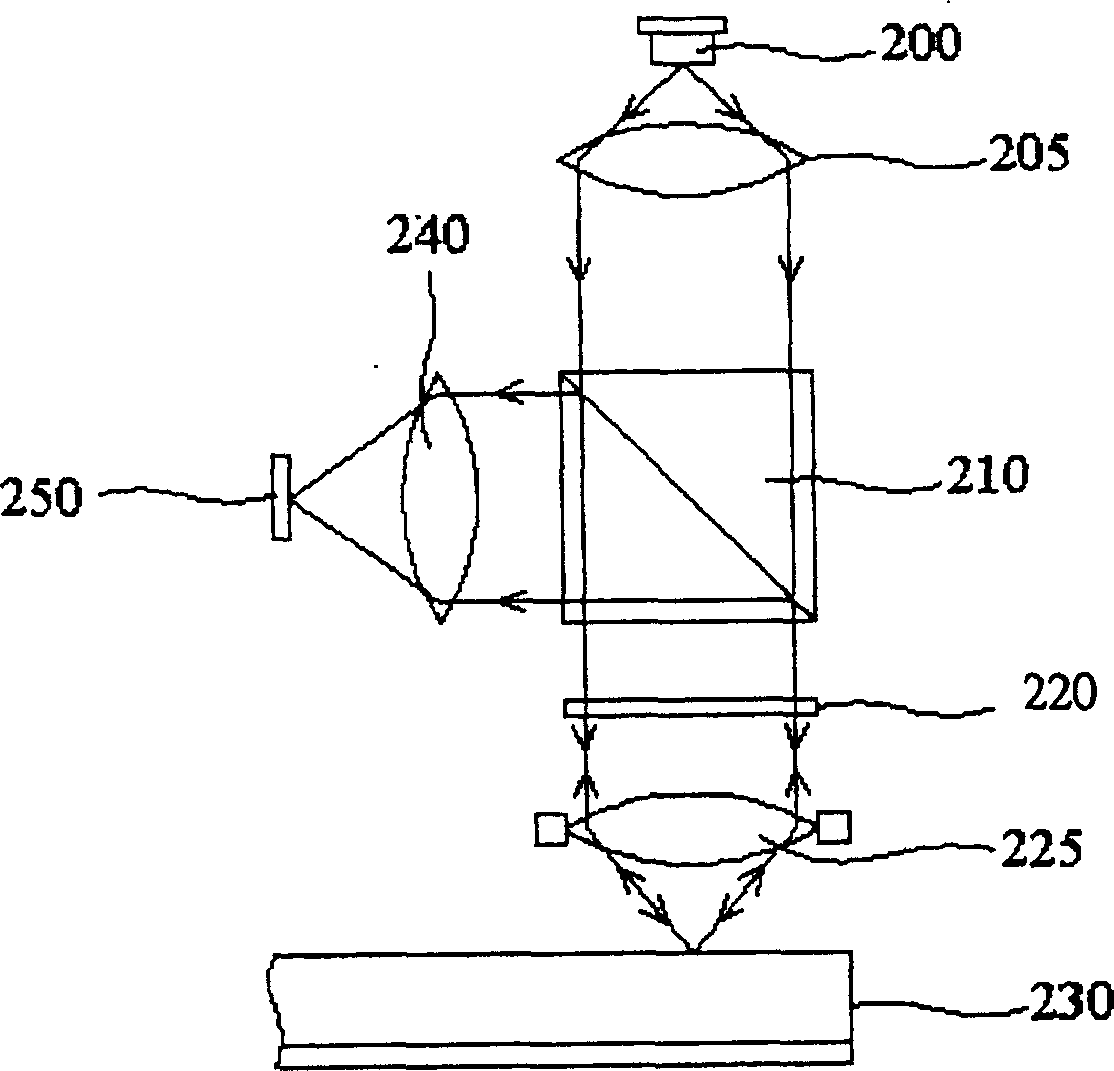

[0028] Generally speaking, the spiral track on the reflective layer of the optical disc will record information of varying brightness and darkness, and the information will be focused on the photodetector through the reflected laser beam. The light intensity received by the light detection unit on the photodetector is summed and converted into an electrical signal to become a high-frequency signal (HF signal). After the optical drive decodes the high-frequency signal, the data recorded on the optical disc can be obtained. Generally speaking, the amplitude of the high-frequency signal is related to the focus of the optical head. For example, if the focus of the optical head is just on the reflective layer, the amplitude of the high-frequency signal will be the largest at this time, and the quality of the high-frequency signal It is also the best; on the contrary, if the focus of the optical head is not located on the reflective layer, the amplitude of the high-frequency signal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com