Float arm assembly and method of manufacture

A technology of float arms and floats, which is applied to household components, buoy liquid level indicators, substructures, etc., can solve the problems of increasing weight, affecting performance, increasing costs, etc., and achieve the effects of improving production efficiency, reducing differences, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

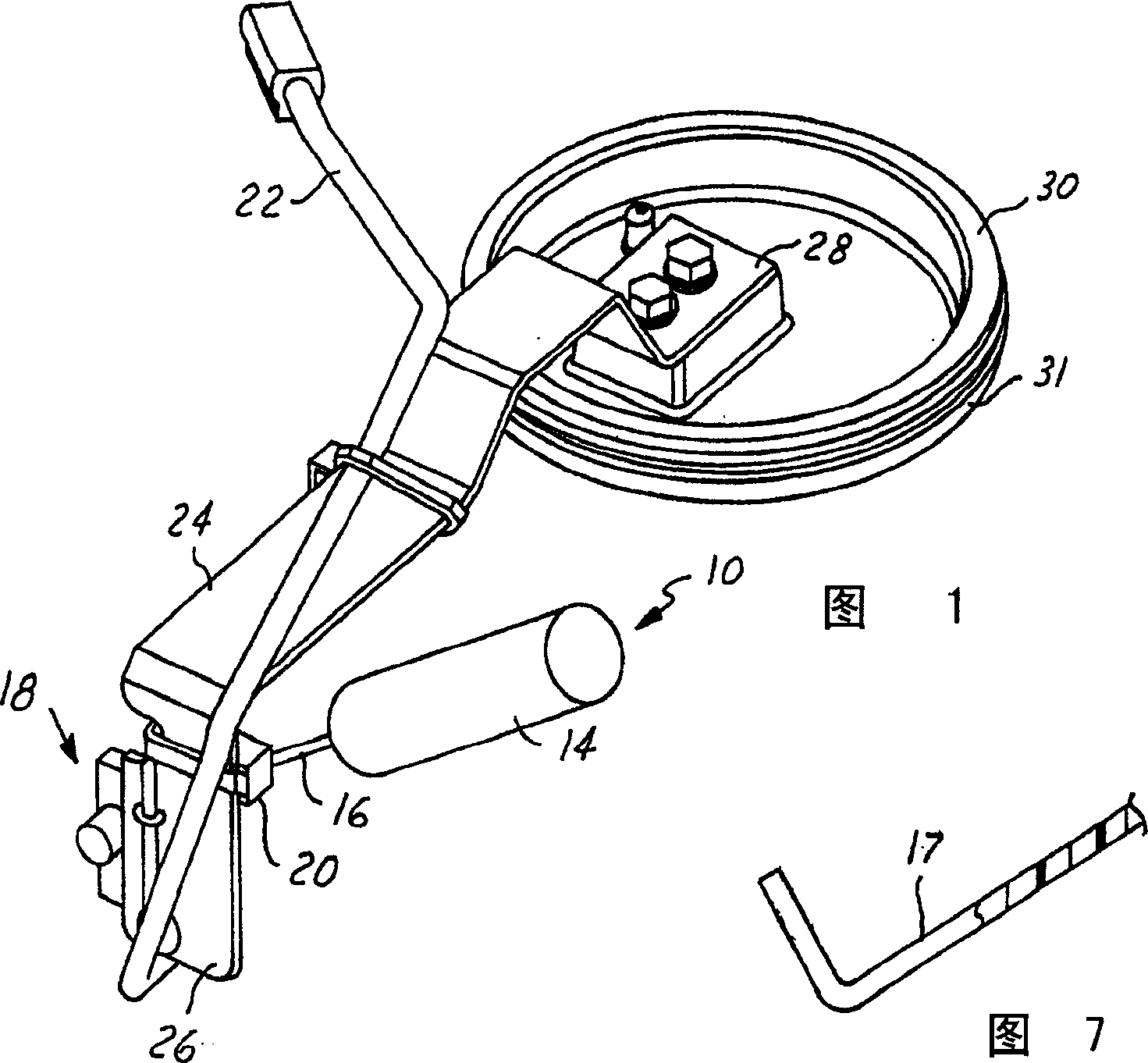

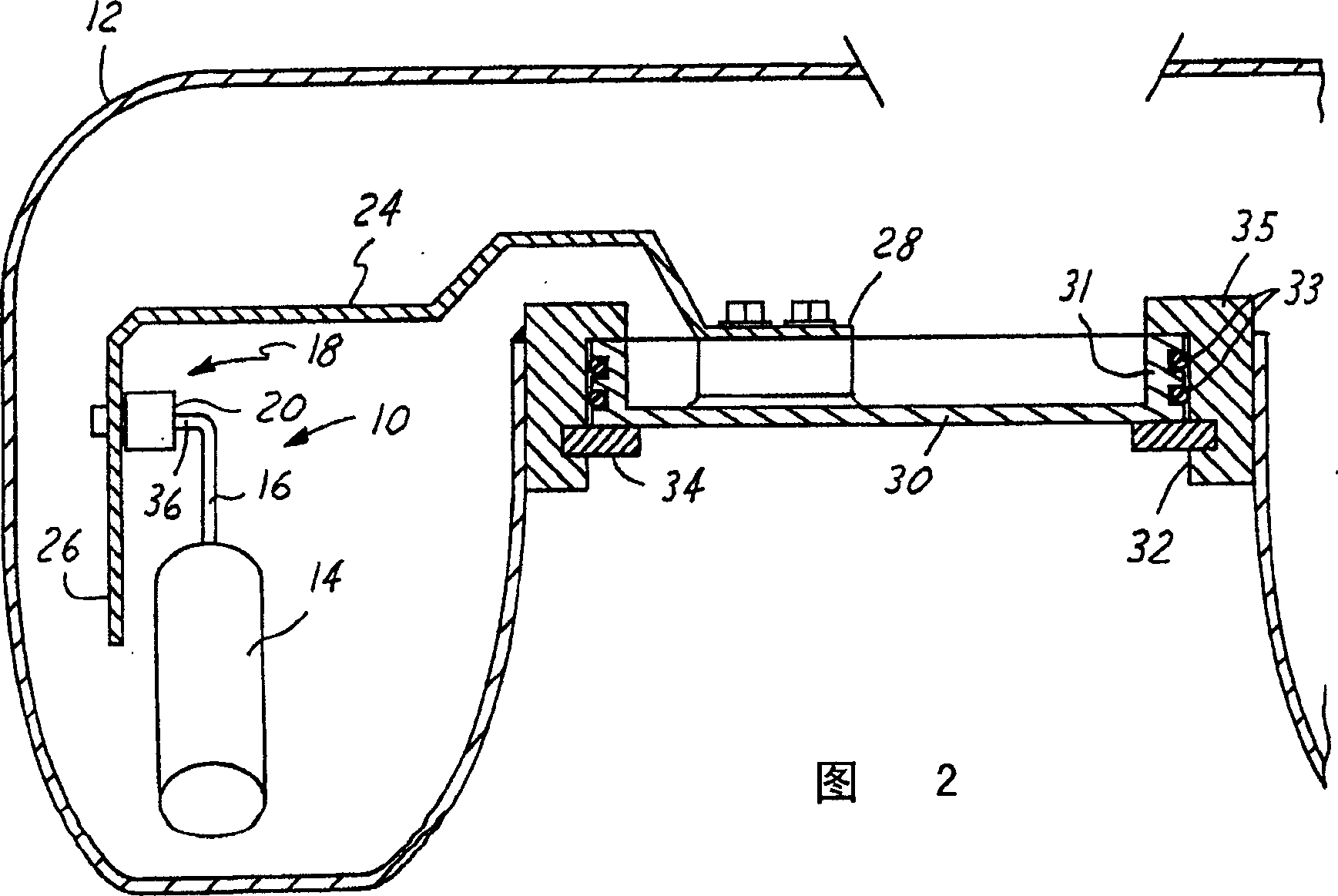

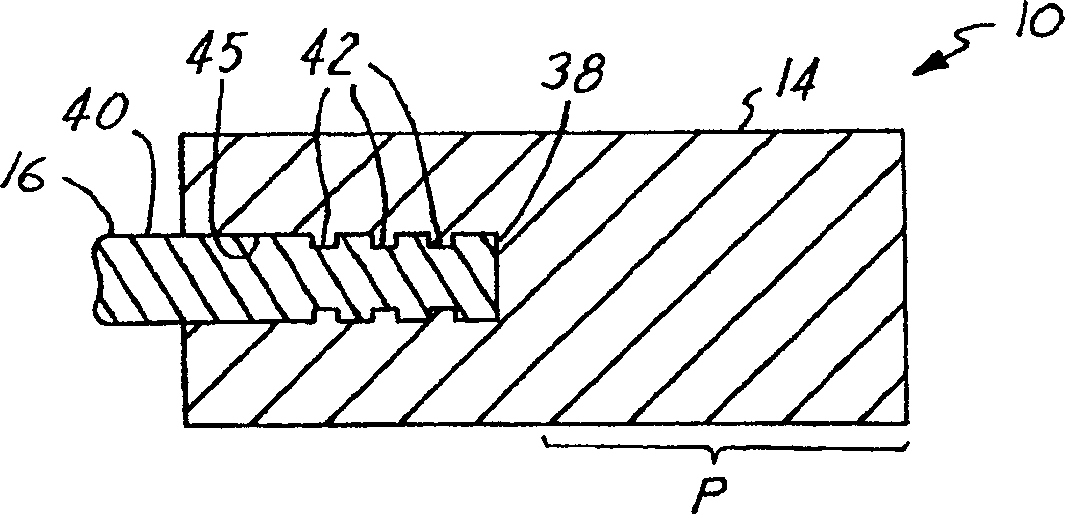

[0016] Referring to Figures 1 and 2 in detail, there is shown a float arm assembly 10 constructed in accordance with one embodiment of the present invention. The float arm assembly 10 is configured for use in a fuel tank 12 (FIG. 2), such as a fuel tank on a motorcycle, RV or vehicle. The assembly 10 has the float 14 molded onto or in at least a portion of the float arm 16 such that the float 14 is carried by the float arm 16 and can be secured to the float arm 16 for removal or lowering between the float 14 and the float arm 16. Slop or jump between float arms 16 . Accordingly, the float arm assembly 10 responds to changes in the fuel position in the fuel tank 12 when there is preferably little relative motion between the float and the float arm 16, and preferably there is no relative motion, thereby It is easy to determine the fuel position in the tank with relative accuracy.

[0017] The float arm assembly 10 is generally configured for use as an integral part of an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com