Warping detection of disk, its control and controller

A control method and optical disc technology, applied in the direction of optical recording/reproduction, head configuration/installation, instruments, etc., can solve the problem of affecting the stability of optical disc reading and writing, shortening the service life of the main shaft motor and servo mechanism of the optical disc drive, and unfavorable Disc data reading and burning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The foregoing and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the accompanying drawings.

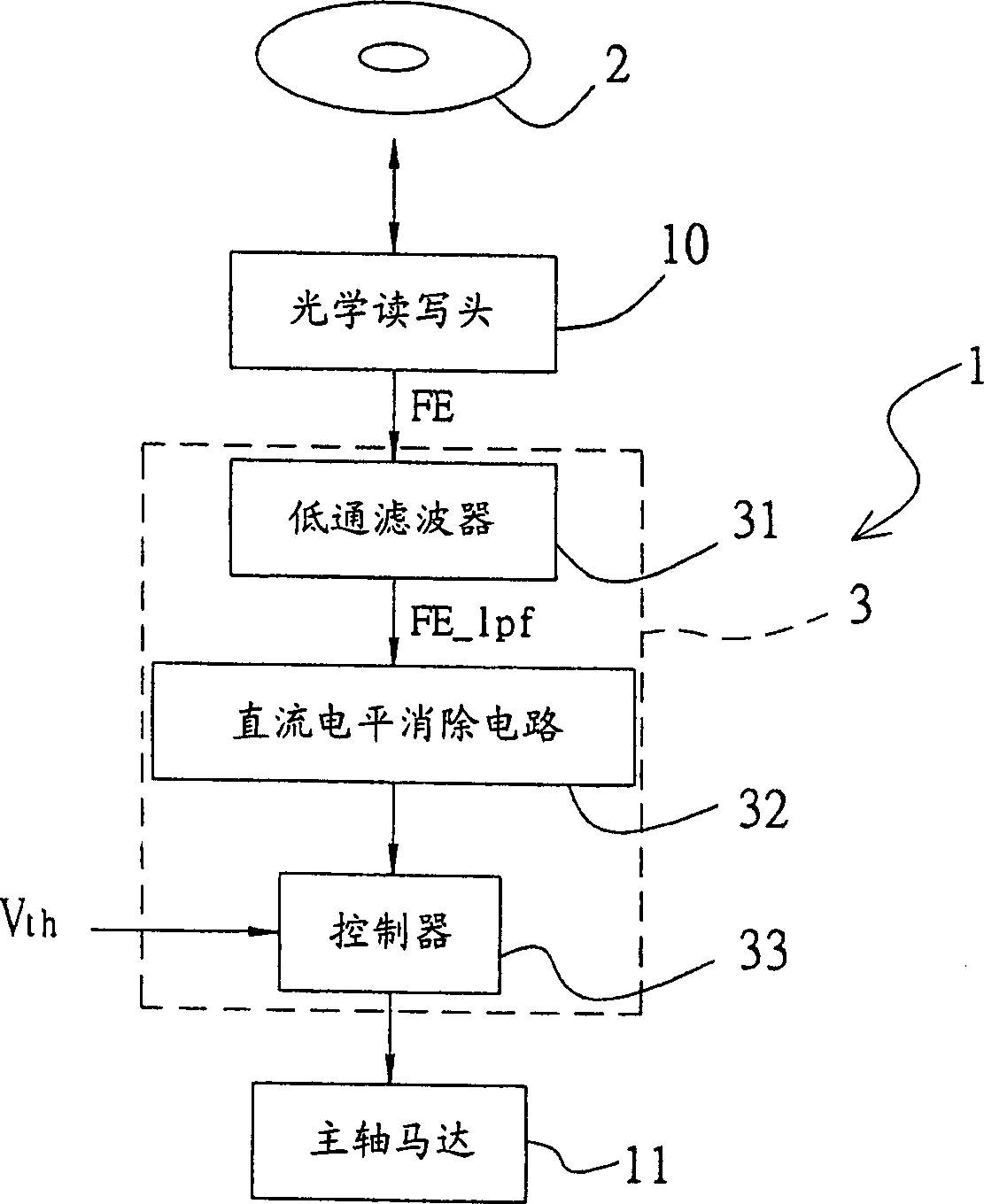

[0022] refer to figure 2 Shown is a preferred embodiment of the digital signal processing device 3 of the present invention, which is set in an optical disc drive 1 to detect and control the maximum rotational speed of the optical disc.

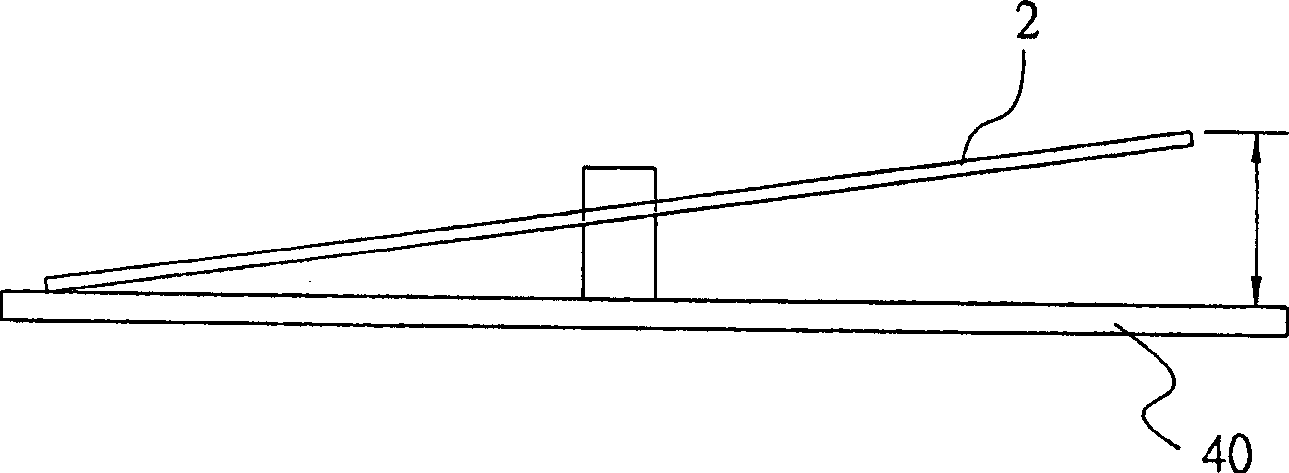

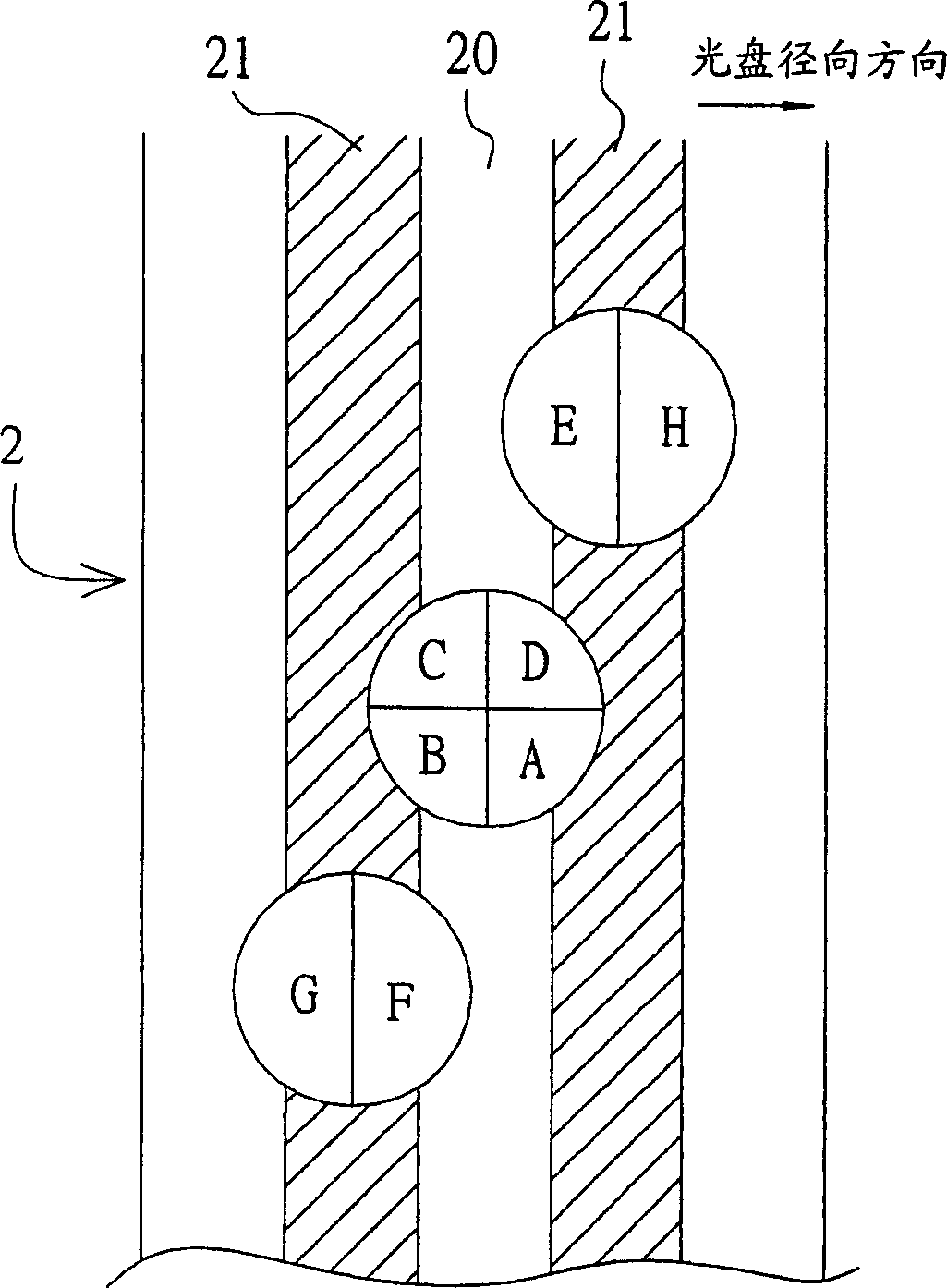

[0023] What should be explained first is that the optical disc drive 1 includes an optical read-write head 10 on which a plurality of photodetectors A, B, C, D, E, F, G, H are arranged, when the optical disc drive 1 reads a Disc 2, such as image 3 As shown, the arrangement positions of the plurality of photodetectors A, B, C, D, E, F, G, H on the optical head 10, and the relative positions of the plurality of photodetectors A~H to the optical disc 2 Location. When photodetectors A to D are positioned on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com