Intensive process of bone

A process method and bone technology, applied in the field of bone processing, can solve the problems of large environmental pollution, pollution, limited consumption of bone resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

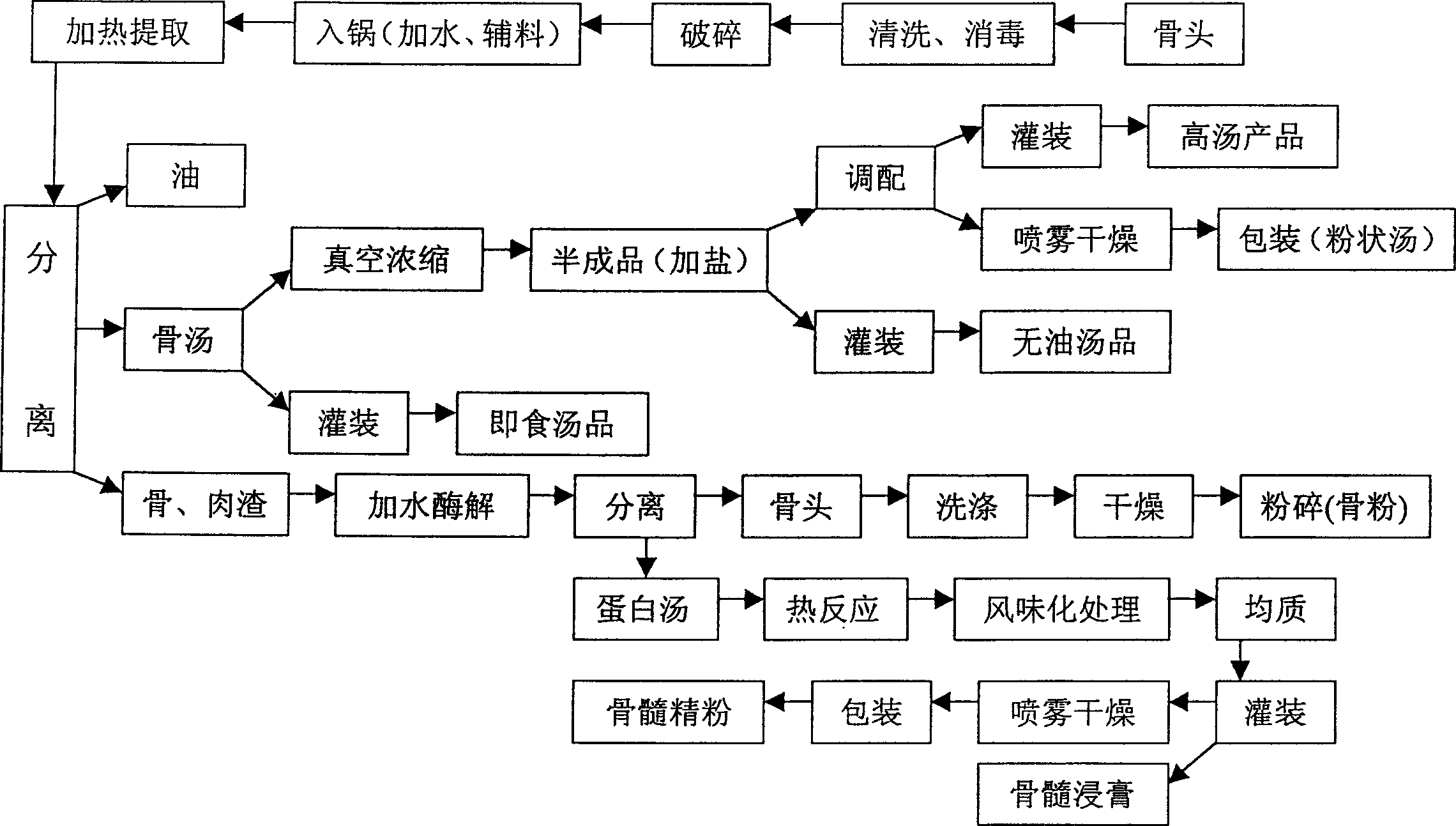

Method used

Image

Examples

Embodiment 1

[0027] Pork bone (broken) 100kg

[0028] Salt 1kg

[0029] Mixed spices of star anise and Chinese prickly ash 1kg

[0030] water 200kg

[0031] Process: (1) First put water into the extraction tank and heat it to above 85°C (or directly add hot water above 85°C).

[0032] (2) Add pork bones, salt, and mixed spices (the spices are wrapped in thick gauze).

[0033] (3) Open the mouth and boil. After boiling for 20 minutes on high heat, change to low heat and boil for 100 minutes.

[0034] (4) Cover and heat up to 115°C (control the temperature rise time within 1 hour, and the pressure<1.5atm).

[0035] (5) Incubate at 115°C for 1 hour.

[0036] (6) Discharging. Separate bone broth, oil, and bone and meat scraps.

[0037] (7-1) Bone broth → vacuum concentration (below 80°C) → blending (adding salt, oil) → homogenization (emulsification) → filling (or spray drying) → finished product (soup product)

[0038] (7-2) Oil soup → oil (flavored sesame oil product)

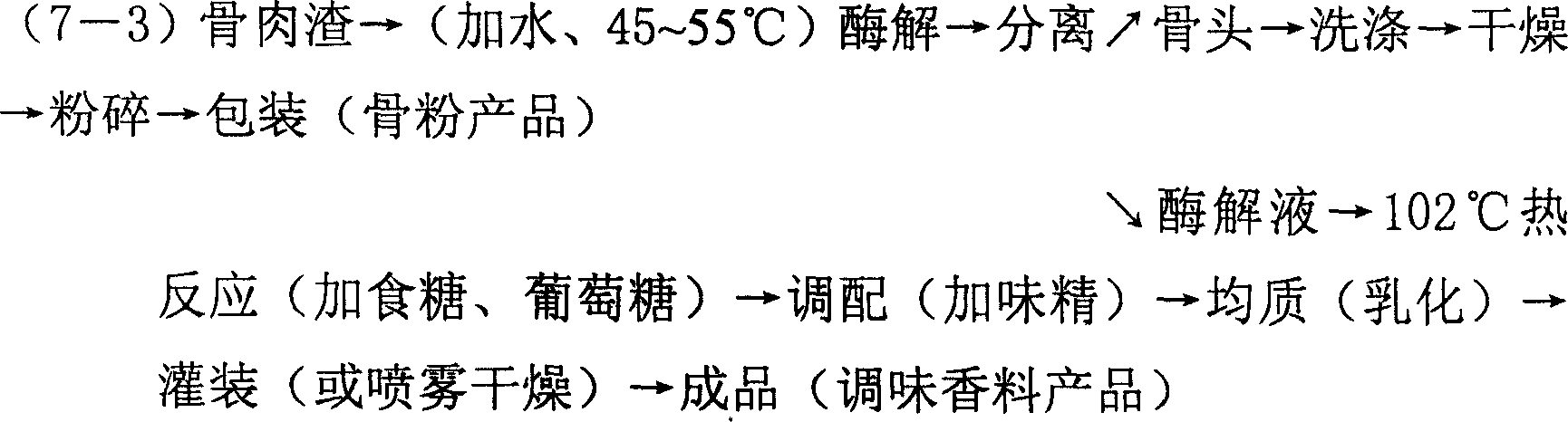

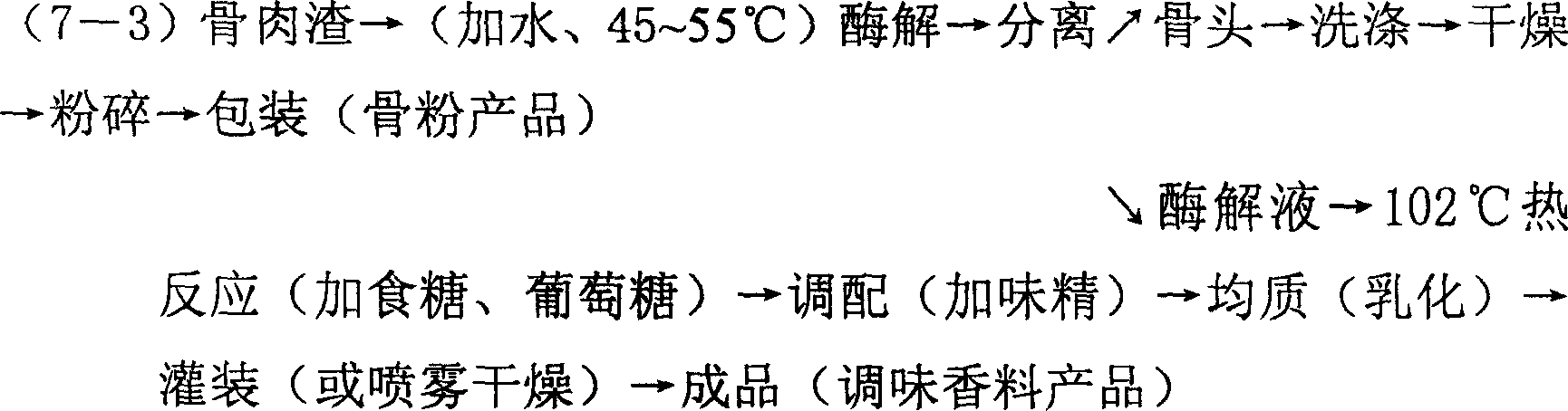

[0039]

Embodiment 2

[0041] Chicken bone (broken) 100kg

[0042] Salt 1kg

[0043] Mixed spices of star anise and Chinese prickly ash 1kg

[0044] water 200kg

[0045] Process: (1) First put water into the extraction tank and heat it to above 85°C (or directly add hot water above 85°C).

[0046] (2) Add chicken bones, salt, and mixed spices (the spices are wrapped in thick gauze).

[0047] (3) Open the mouth and boil. After boiling for 20 minutes on high heat, change to low heat and boil for 100 minutes.

[0048] (4) Cover and heat up to 115°C (control the temperature rise time within 1 hour, and the pressure<1.5atm).

[0049] (5) Incubate at 115°C for 1 hour.

[0050] (6) Discharging. Separate bone broth, oil, and bone and meat scraps.

[0051] (7-1) Bone broth → vacuum concentration (below 80°C) → blending (adding salt, oil) → homogenization (emulsification) → filling (or spray drying) → finished product (soup product)

[0052] (7-2) Oil soup → oil (flavored sesame oil product)

[0053]...

Embodiment 3

[0055] Beef bone (broken) 100kg

[0056] Salt 1kg

[0057] Mixed spices of star anise and Chinese prickly ash 1kg

[0058] water 200kg

[0059] Process: (1) First put water into the extraction tank and heat it to above 85°C (or directly add hot water above 85°C).

[0060] (2) Add beef bones, salt, and mixed spices (the spices are wrapped in thick gauze).

[0061] (3) Open the mouth and boil. After boiling for 20 minutes on high heat, change to low heat and boil for 100 minutes.

[0062] (4) Cover and heat up to 115°C (control the temperature rise time within 1 hour, and the pressure<1.5atm).

[0063] (5) Incubate at 115°C for 1 hour.

[0064] (6) Discharging. Separate bone broth, oil, and bone and meat scraps.

[0065] (7-1) Bone broth → vacuum concentration (below 80°C) → blending (adding salt, oil) → homogenization (emulsification) → filling (or spray drying) → finished product (soup product)

[0066] (7-2) Oil soup → oil (flavored sesame oil product)

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com