Process of separating fucoxanthin from algae

A fucoxanthin and seaweed technology, applied in the direction of organic chemistry, can solve the problems of high alginate and polysaccharide content, difficulty in extraction, time-consuming and labor-intensive work, and achieve fast separation speed, low cost and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

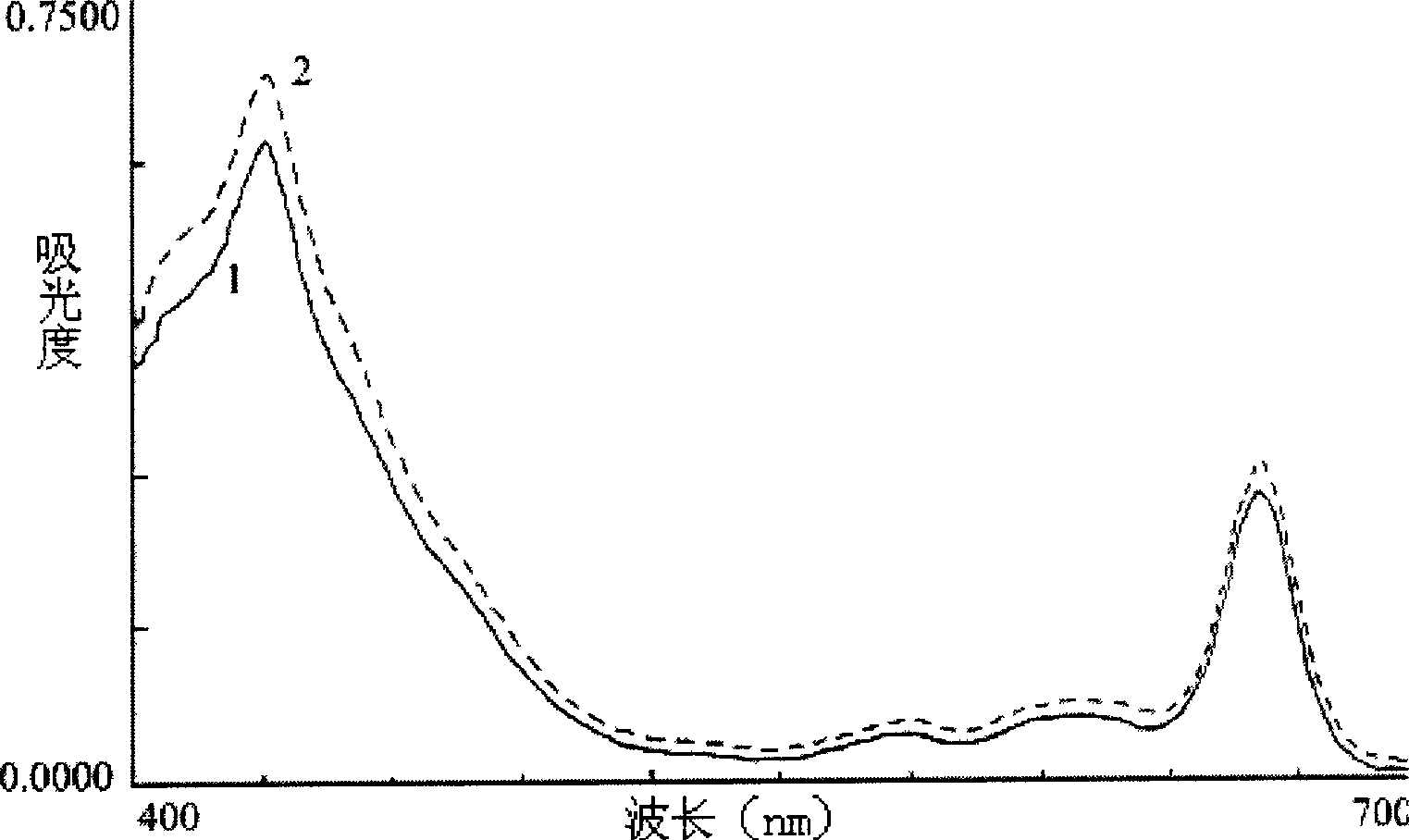

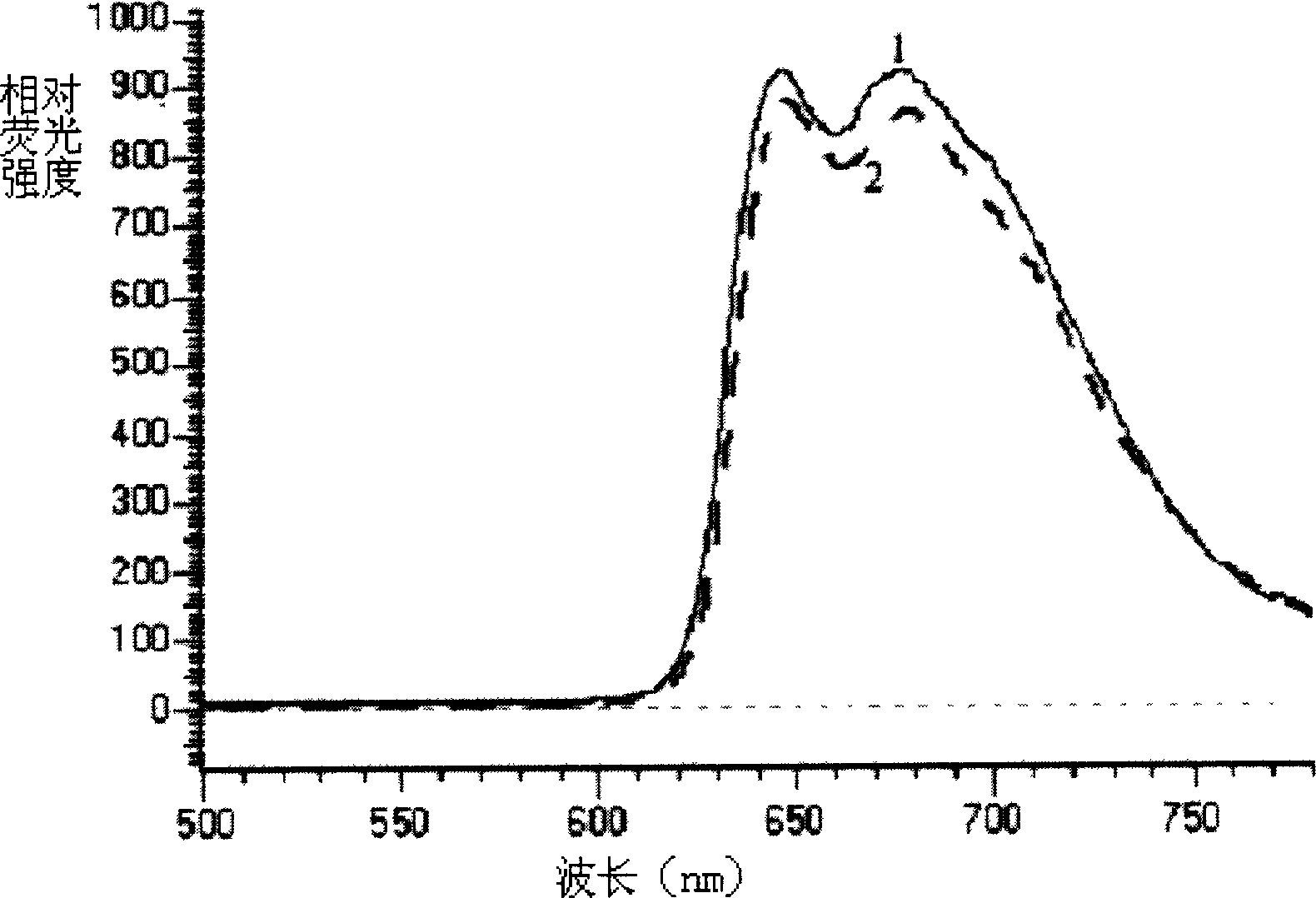

Embodiment 1

[0037] Take out the fresh or frozen kelp root, thaw it at room temperature, wash it 3 times with distilled water to remove the salt ions on the surface of the algae, and then use absorbent paper to dry the surface water. Weigh 1g of kelp root into a small beaker, add 3ml of DMSO, seal the mouth of the beaker with two layers of plastic wrap, extract in the dark for 50min, pour the extract into a brown bottle, wash the residue with 3ml of distilled water, and pour into a brown bottle. Determination of absorbance A 665 , A 631 , A 582 , A 480 , calculate the pigment concentration according to the following formula: [chl a]=A 665 / 72.8; [chl c]=(A 631 +A 582 -0.298A 665 ) / 61.8; [Fucoxanthin]=(A 480 -0.723 (A 631 +A 582 -0.298A 665 )-0.049A 665 ) / 130. The calculated yield is based on the amount of pigment proposed in each gram of kelp root, and the results are shown in Table 1.

[0038] deal with

Embodiment 2

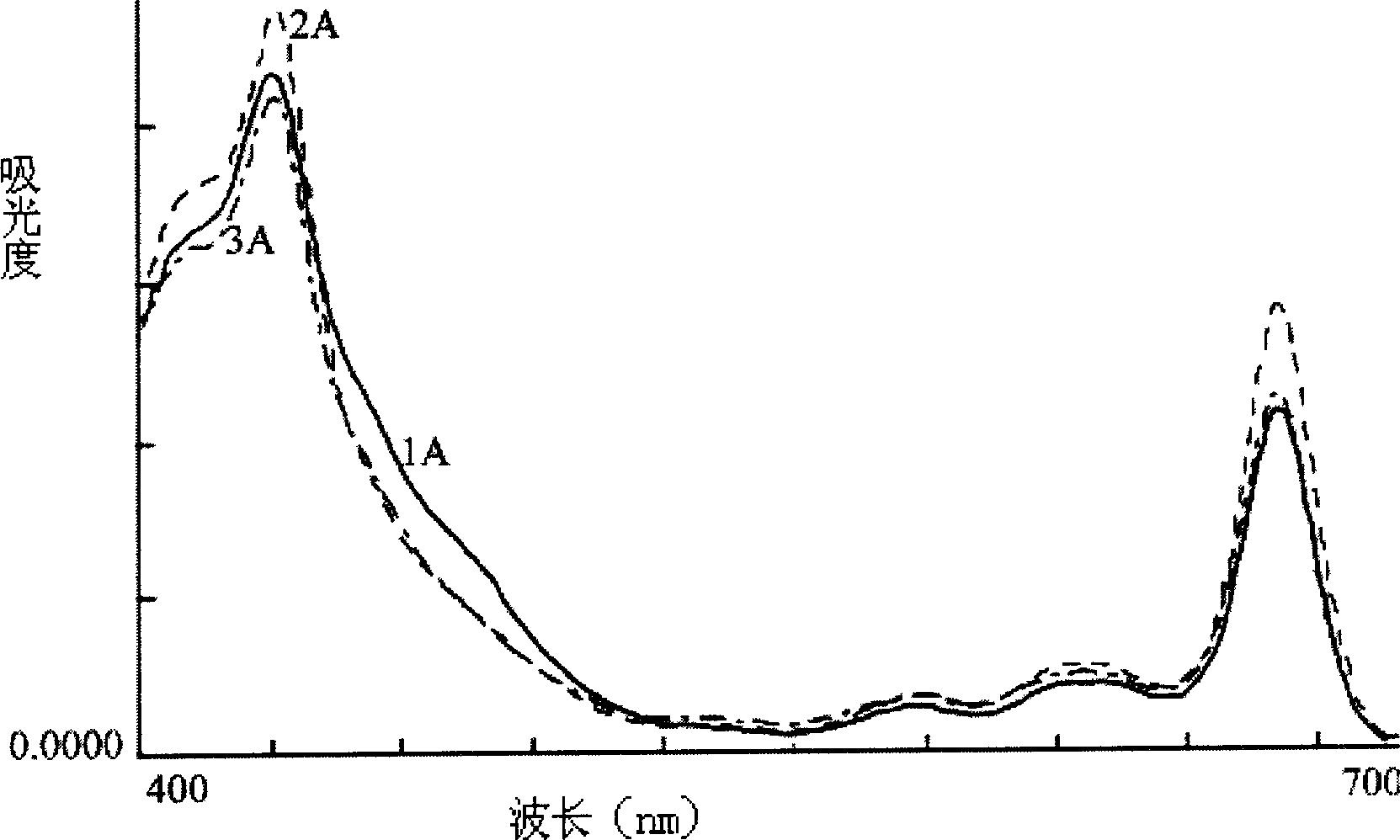

[0040] Take out the fresh or frozen kelp root, thaw it at room temperature, wash it 3 times with distilled water to remove the salt ions on the surface of the algae, and then use absorbent paper to dry the surface water. Weigh 1g of kelp root into a small beaker, add 4ml of DMSO, seal the mouth of the beaker with two layers of plastic wrap, extract in the dark for 15 minutes, pour the extract into a brown bottle, and wash the residue with 4ml of distilled water Pour into a brown bottle. Absorbance measurement and calculation method of pigment concentration are the same as in Example 1, and the calculated yield is based on the amount of pigment proposed in each gram of kelp root. The results are shown in Table 2.

[0041] deal with

Embodiment 3

[0043] Take out the fresh or frozen kelp root, thaw it at room temperature, wash it 5 times with distilled water to remove the salt ions on the surface of the algae, and then use absorbent paper to dry the surface water. Weigh 1g of kelp root into a small beaker, add 7ml of DMSO, seal the mouth of the beaker with two layers of plastic wrap, extract in the dark for 30 minutes, pour the extract into a brown bottle, and wash the residue with 7ml of distilled water Pour into a brown bottle. The absorbance measurement and pigment concentration calculation method are the same as in Example 1, and the calculated yield is based on the amount of pigment proposed in each gram of kelp root. The results are shown in Table 3.

[0044] deal with

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com