Free flow conveyance system

一种输送系统、流量的技术,应用在输送系统领域,能够解决电动马达电能消耗大、占用人力和时间、运行成本无法降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

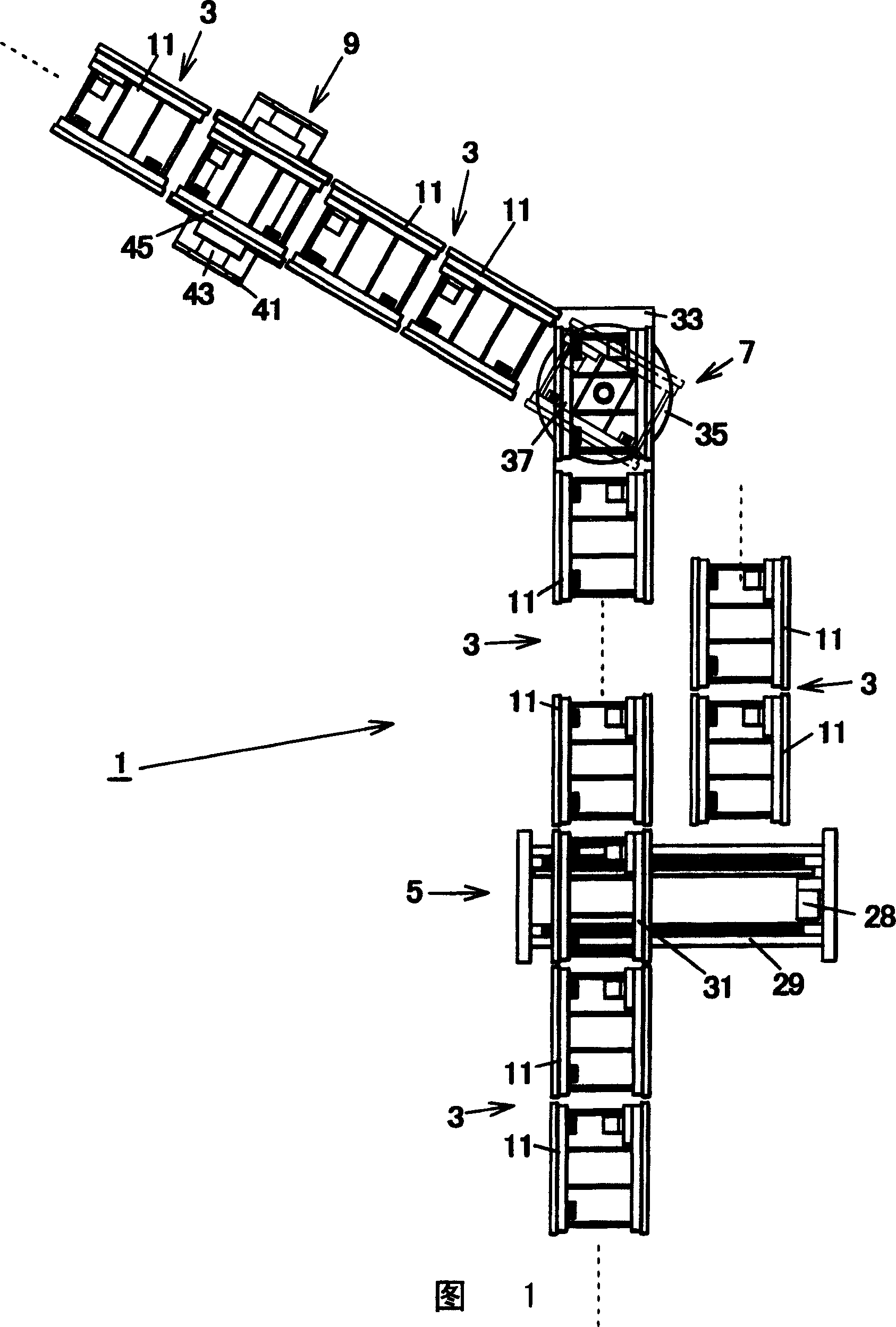

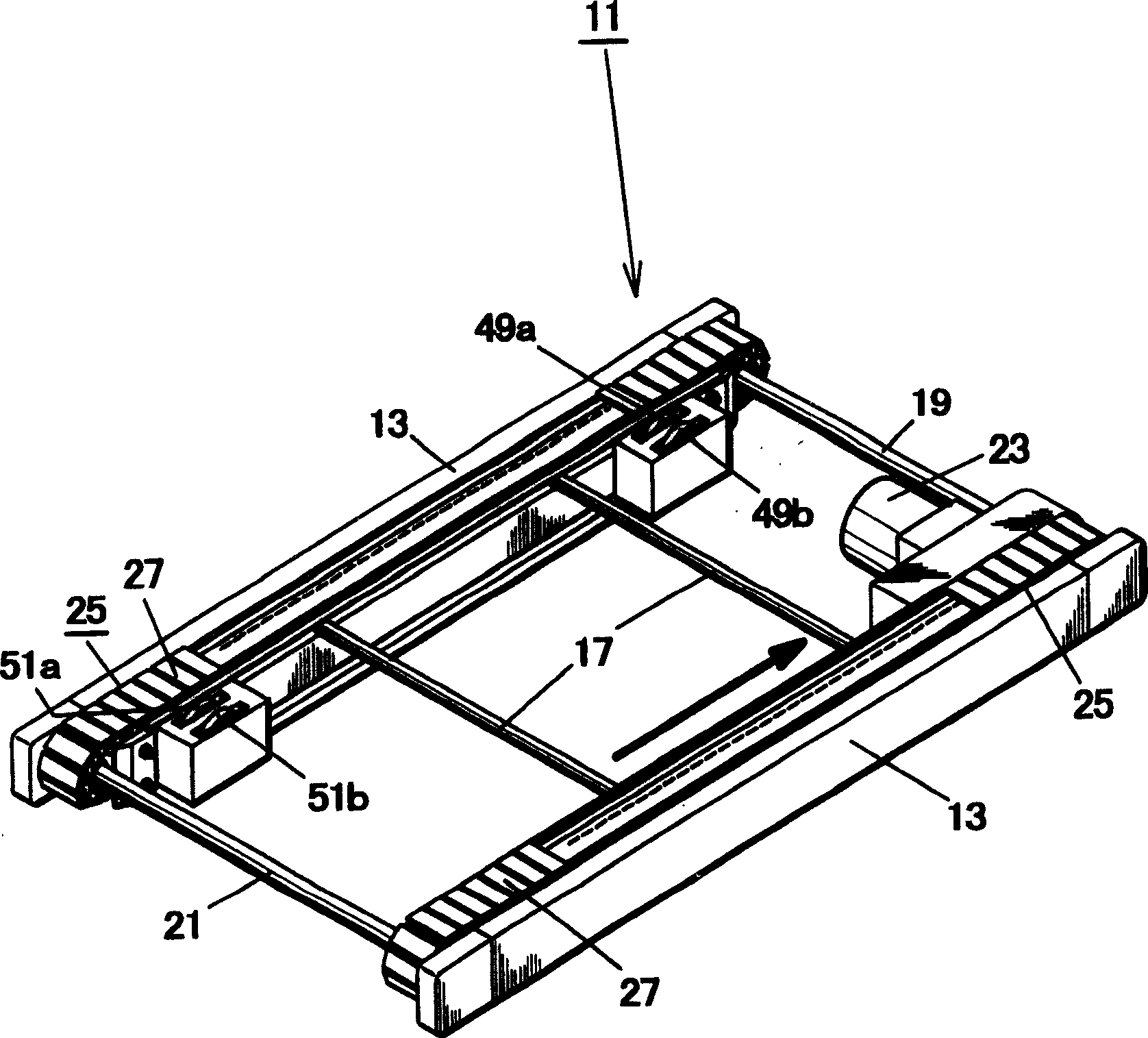

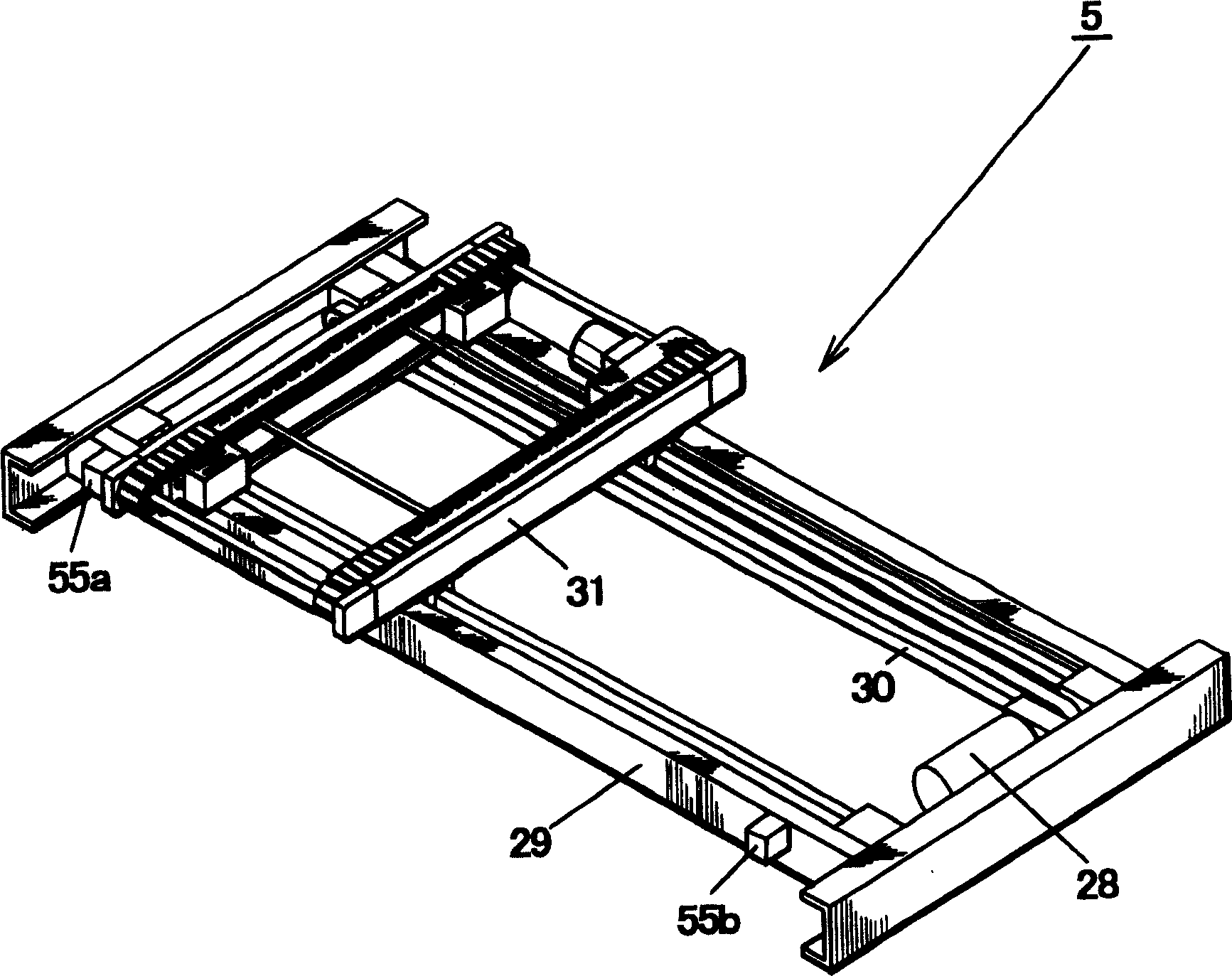

[0023] In Figure 1 to Figure 5 Among them, the embodied free flow conveying system 1 of the present invention consists of a plurality of linear conveying devices 3 (for ease of description, it is assumed that the system is composed of 5 linear conveying devices 3, which are respectively the 1st to the 5th linear conveying devices 3), be arranged between the 2nd and the 3rd linear conveying device 3 of for example the 1st linear conveying device 3 and arrange side by side, can form the conveying path from the 1st linear conveying device 3 to the 2nd and the 3rd A branch conveying device 5 selectively switched by a certain linear conveying device 3, a rotary conveying device 7 arranged, for example, between the 3rd and 4th linear conveying device 3 disposed at a desired angle, and arranged at, for example, The lifting conveying device 9 between the 4th and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com