Spray gun

A technology of spray gun and atomizing nozzle, applied in the field of spray gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

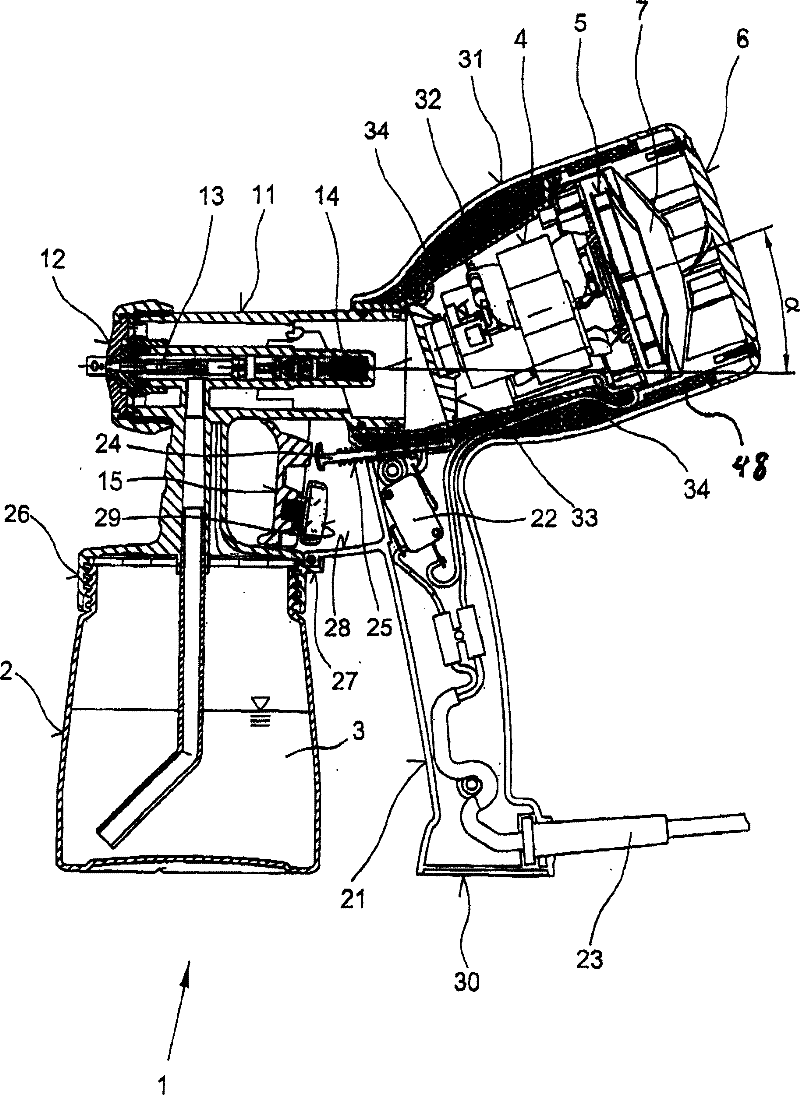

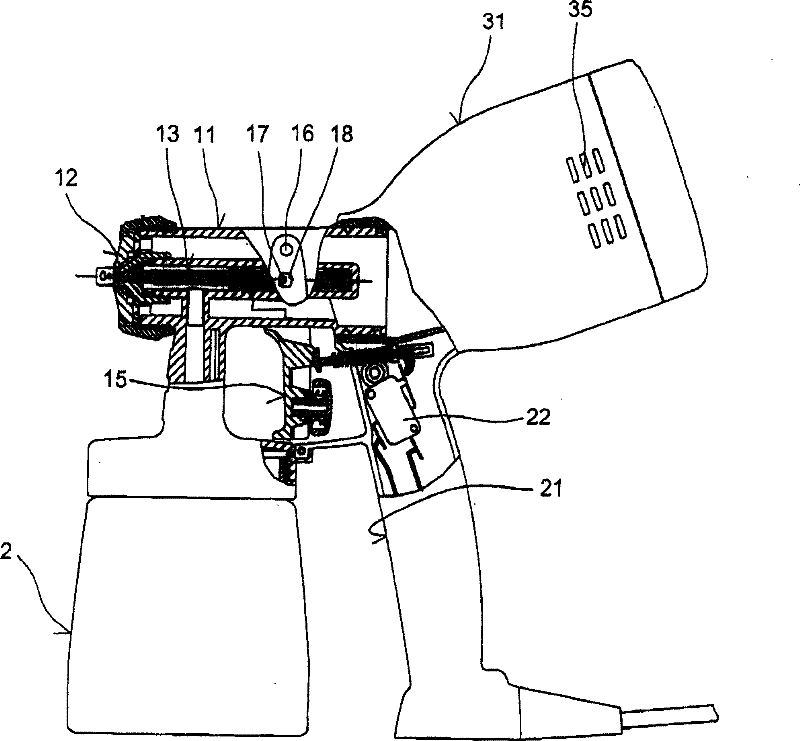

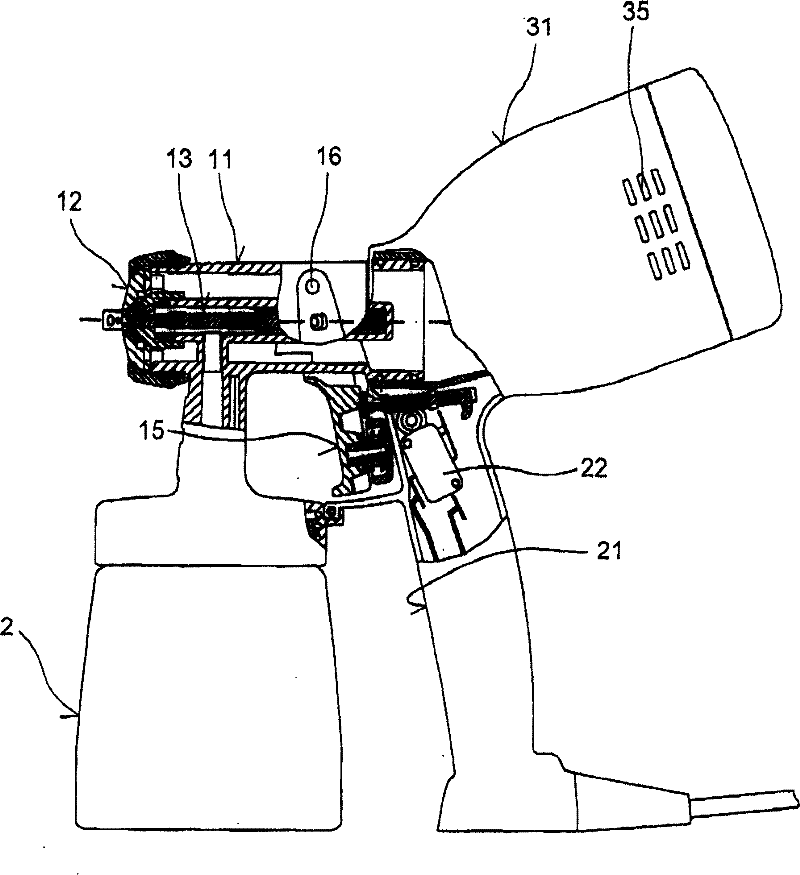

[0036] figure 1 , 2 , 3 and 4 and denoted as 1 or 1' are used to atomize paint, varnish or similar medium 3 located in storage container 2, which can be supplied to the workpiece by air flow. In the illustrated embodiment, the air flow for atomization is formed by an air turbine 5 which may be driven by an electric drive motor 4 . In addition, the air turbine 5 is provided with a muffler 6 in order to reduce input noise, while a cavity 7 is formed between the muffler 6 and the air turbine 5 for the same purpose.

[0037] The spray gun 1 mainly includes a sleeve 11 connected with a storage container 2, an atomizing nozzle 12 equipped with an axially adjustable nozzle needle 13 and connected to the sleeve 11, a handle 21, and an accessory 31 formed on the handle 21. In the case of the gun 1 , the attachment 31 is firmly connected to the sleeve and houses the air turbine 5 , its electric drive motor 4 and the muffler 6 . The spray gun can be driven by a lever 15 operated agains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com