Circuit breaker and terminal cover

A terminal cover and circuit breaker technology, applied in circuit breaker parts, circuit breaker contacts, switch terminals/connections, etc., can solve problems such as difficulty and difficulty in disassembling the terminal cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

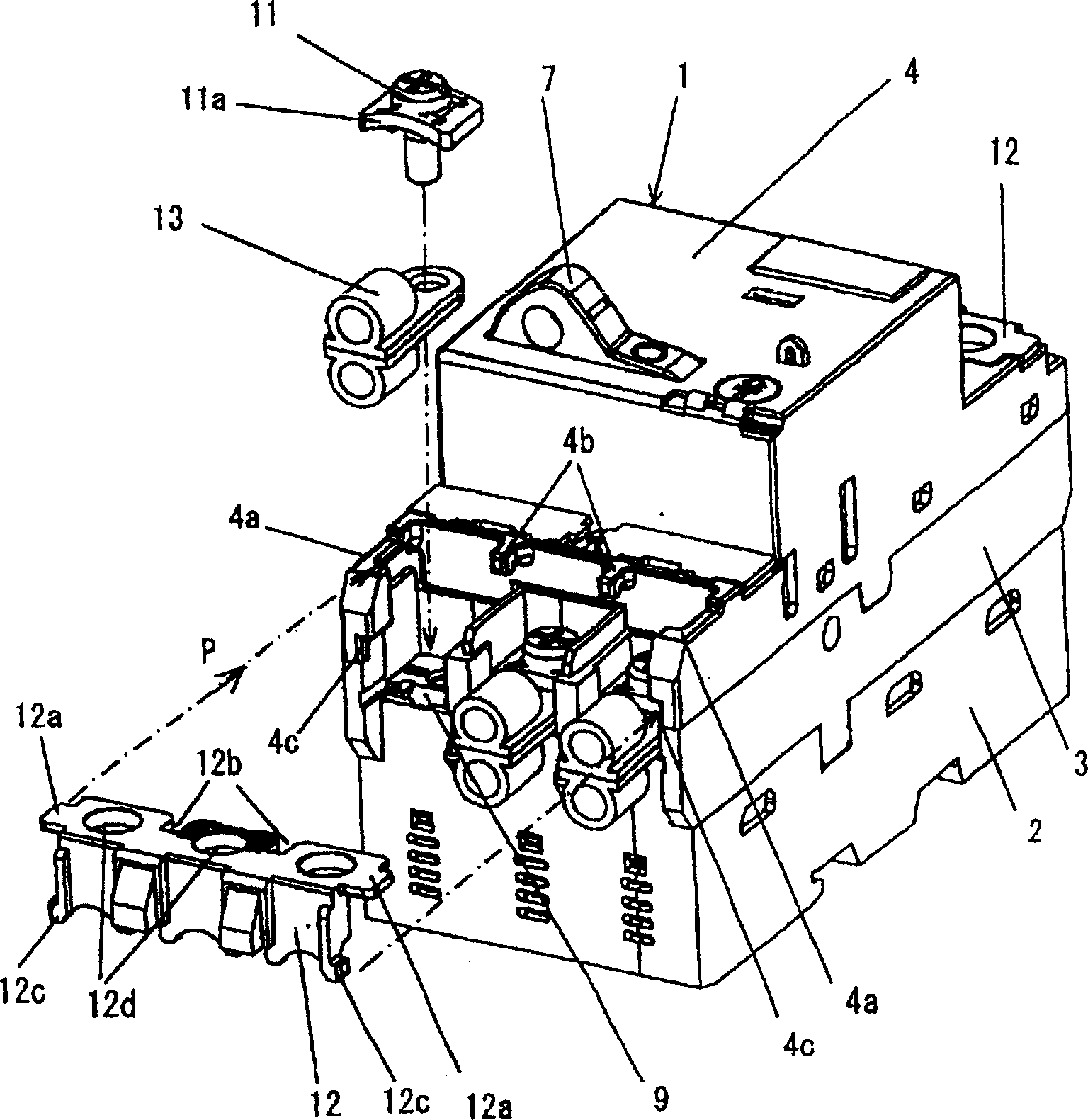

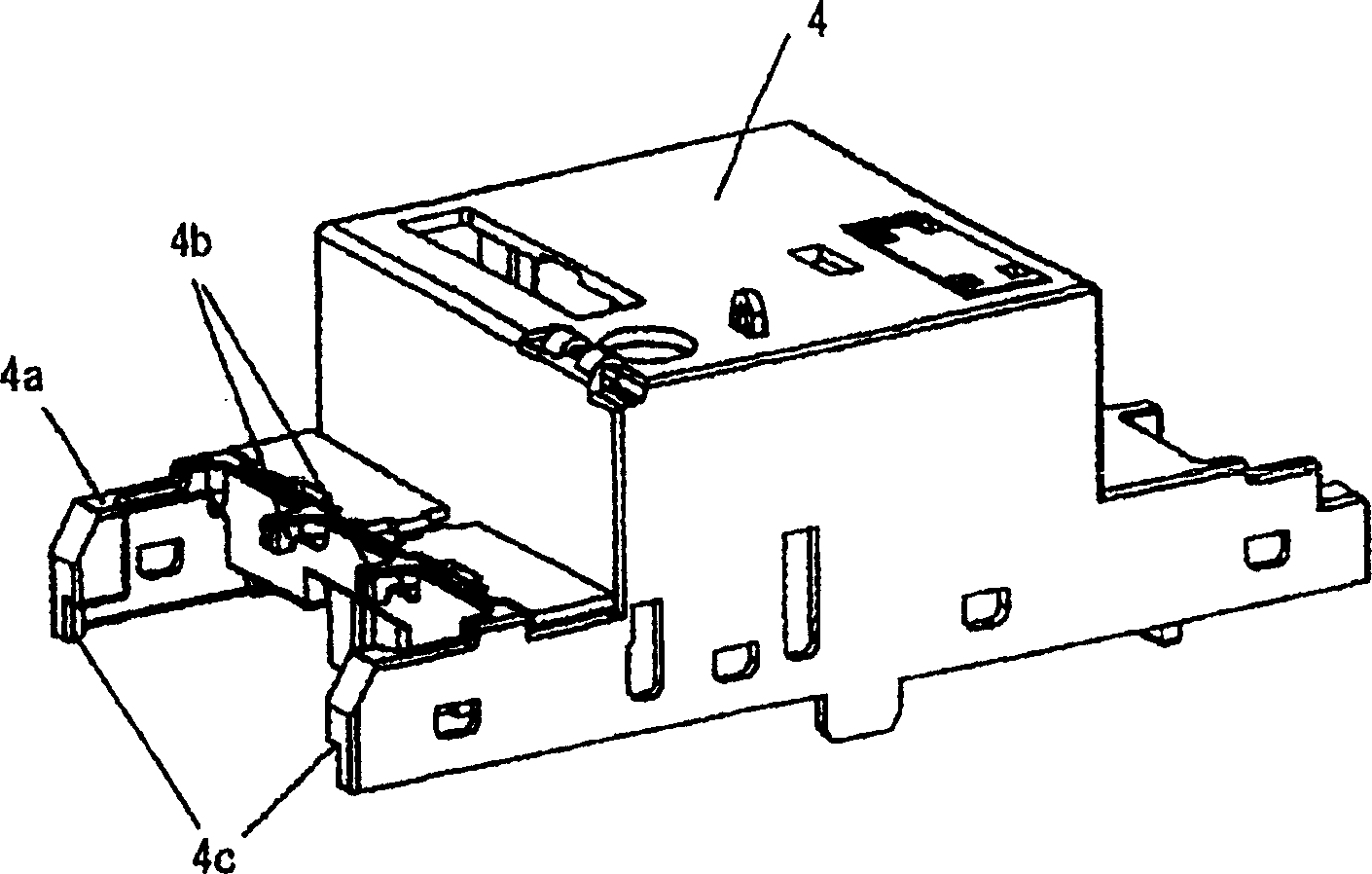

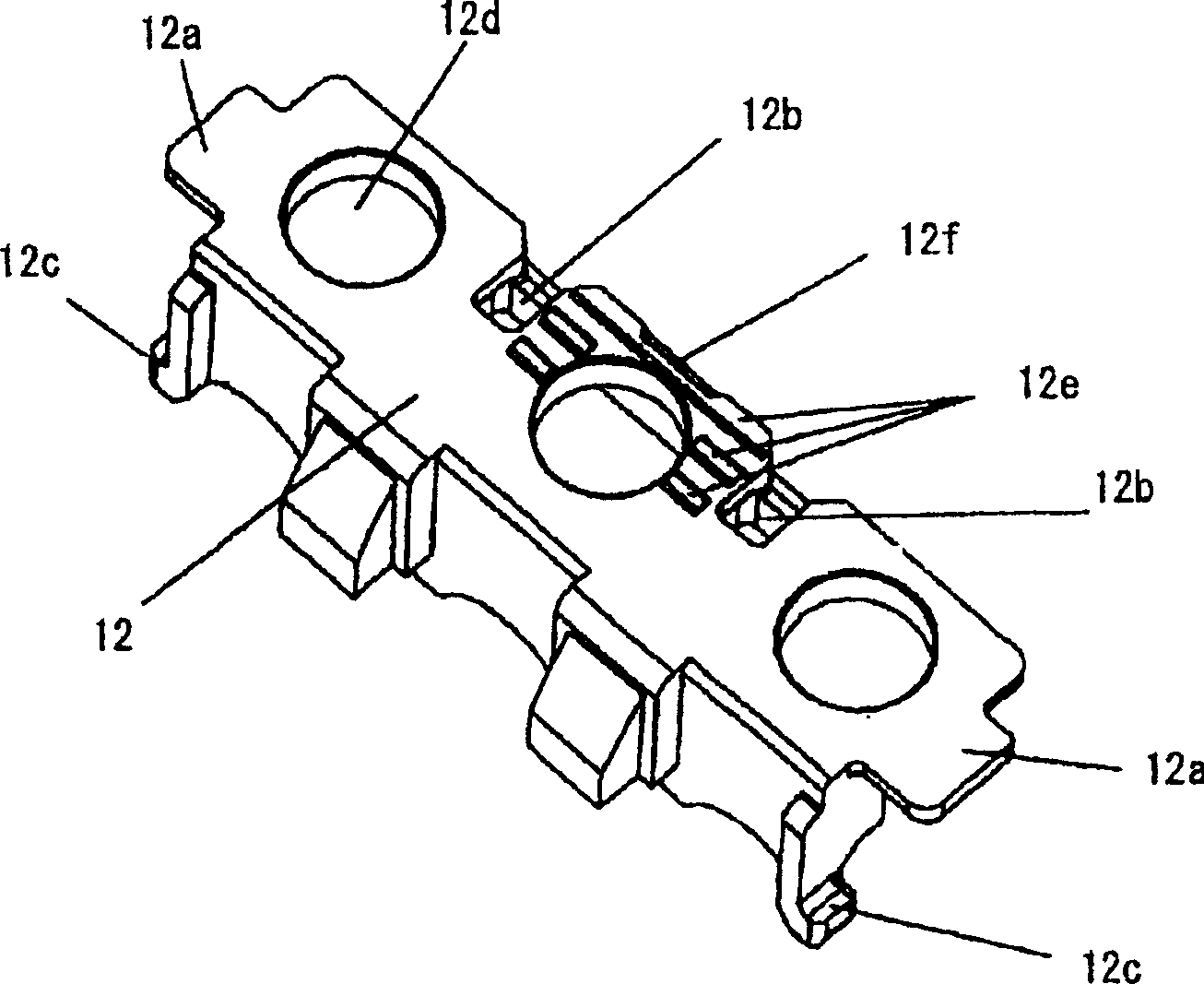

[0024] Figure 1 to Figure 5 Examples are given corresponding to the first to sixth aspects of the present invention. First, in Figure 4A and 4B The overall structure of the circuit breaker is given in, figure 1 The main body case 1 shown in is a molded resin case having a three-part structure consisting of a lower case 2 , an intermediate case 3 and a cover 4 . In the main body casing 1 are incorporated basic components such as a current breaking unit 5 , a switch mechanism 6 , a switch operating handle 7 and an overcurrent tripping device 8 . In addition, on one end and the other end of the main body case 1, the power supply side terminal 9 and the load side terminal 10 of the main circuit are respectively taken out, and on each terminal, a terminal screw 11 is screwed together with a washer 11a to form an external wiring of the terminal section. In addition, the terminal cover 12 formed to cover the front and top of the terminal part according to the present invention...

Embodiment 2

[0030] Next, refer to Figure 6 The elongated terminal cover corresponding to the seventh and eighth aspects of the present invention will be described.

[0031] exist figure 1 In the shown embodiment 1, although the terminal cover 12 covers the upper part and the front part of the terminal screw 11 when it is at the position connected with the main body case 1, the solderless terminal 13 connected to the terminal screw 11 is The cable clamp part protrudes from the front and is not covered and exposed. Thus, the solderless terminal provided as the bare solderless terminal 13 without insulation may be directly touched by hand, which may cause an electric shock. In addition, when the solderless terminals 13 drawn forward from the terminal portion are fastened with the direction of pulling out the cable clamp portion deviated to the left or right, the distance between adjacent solderless terminals 13 is reduced. Small, so it is impossible to ensure the necessary insulation dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com