Support assembly for output shaft of reciprocating power tool

A technology for supporting components and power tools, applied in the direction of manufacturing tools, bearing assembly, bearing components, etc., can solve the problem of difficult jigsaw saw blades to leave the expected cutting line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

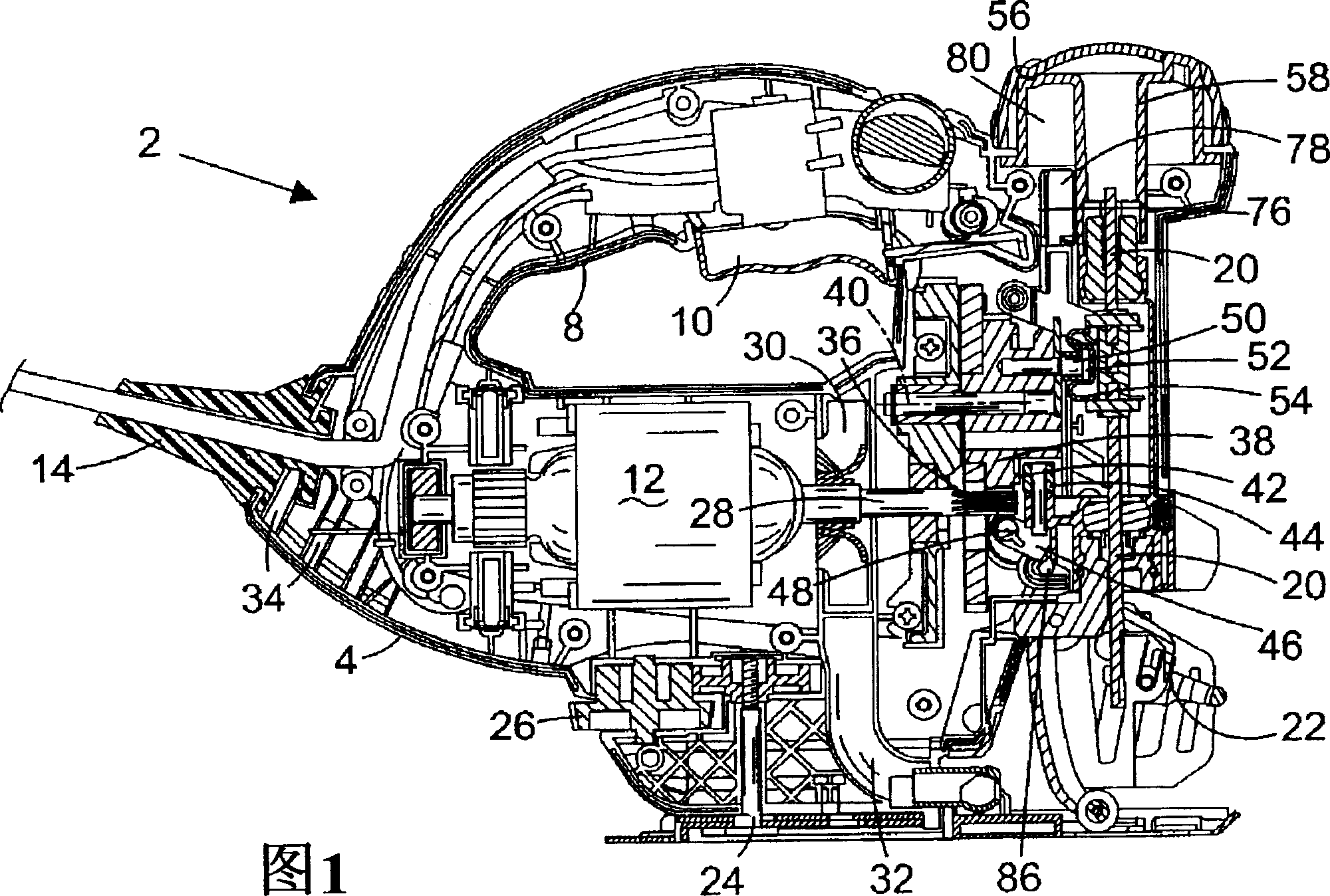

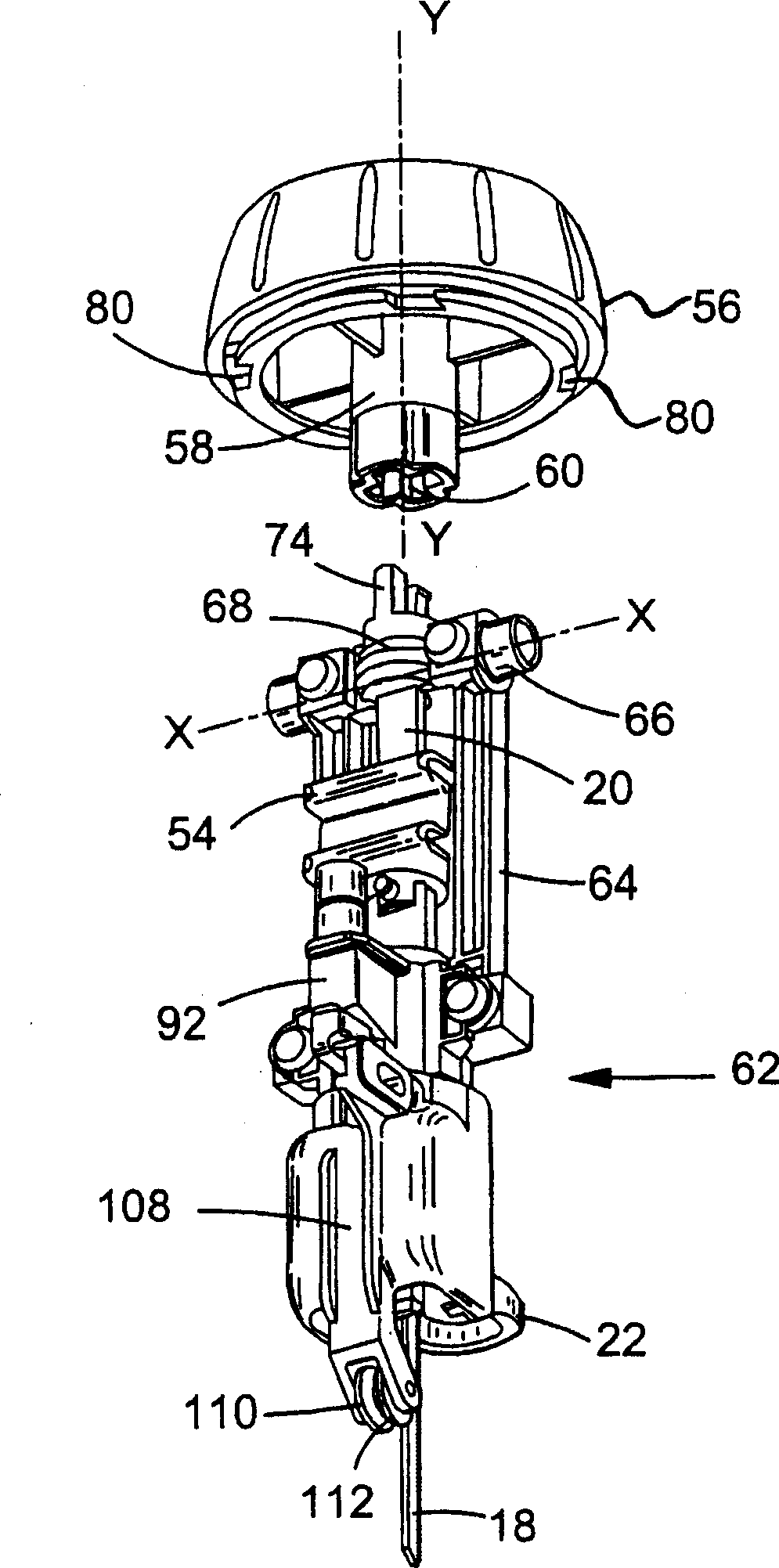

[0049] Referring to FIG. 1 , the jigsaw 2 has a housing 4 comprising two shell-like halves 6 (only one shown in FIG. 1 ) forming a handle 8 having a start switch 10 for manipulating a motor 12. Power is supplied via cable 14 . A base plate 16 for placement on a workpiece (not shown) is located in the lower portion of the housing 4, and a jigsaw blade 18 ( figure 2 ) is connected to the lower end of the output shaft 20 by the saw blade clamping mechanism 22. The operation of the blade clamping mechanism 22 is not relevant to the understanding of the present invention and thus will not be described in detail here. The orientation of the base plate 16 can be adjusted relative to the housing 4 to enable bevel cutting and can be secured with clamping screws 24 operated by a locking mechanism 26, which is also not relevant to the understanding of the invention and therefore will not be described in detail here.

[0050]The motor 12 drives a shaft 28 carrying a fan 30 . As the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com