Automatic control method for dust concentration and mating power supply device therefor

A dust concentration and dust technology, which is applied in the field of automatic dust concentration control and supporting power supply devices, can solve the problems of poor control quality, increased labor, and untimely dust emission concentration, so as to achieve good control quality and timely control. Good, improve the effect of dust emission concentration indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

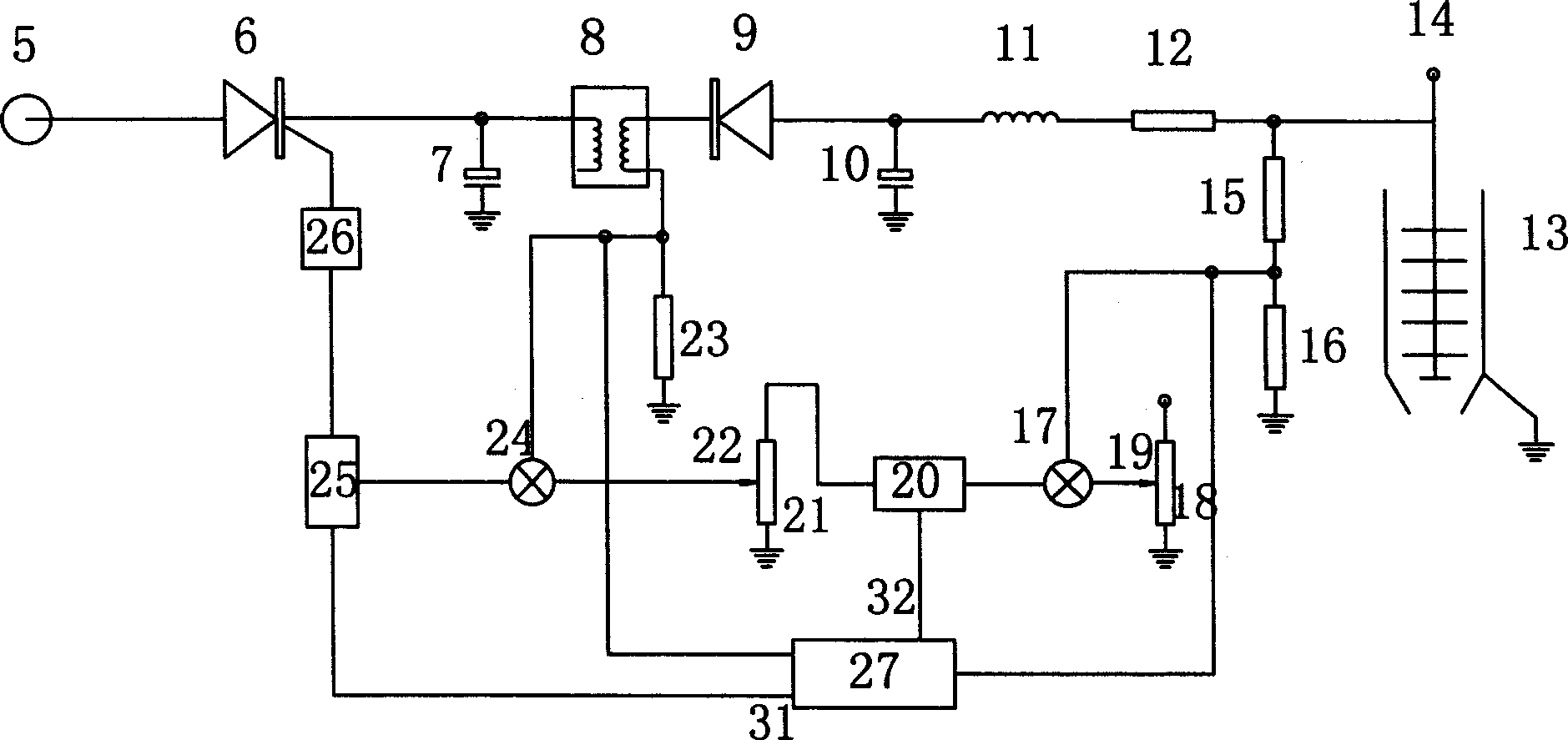

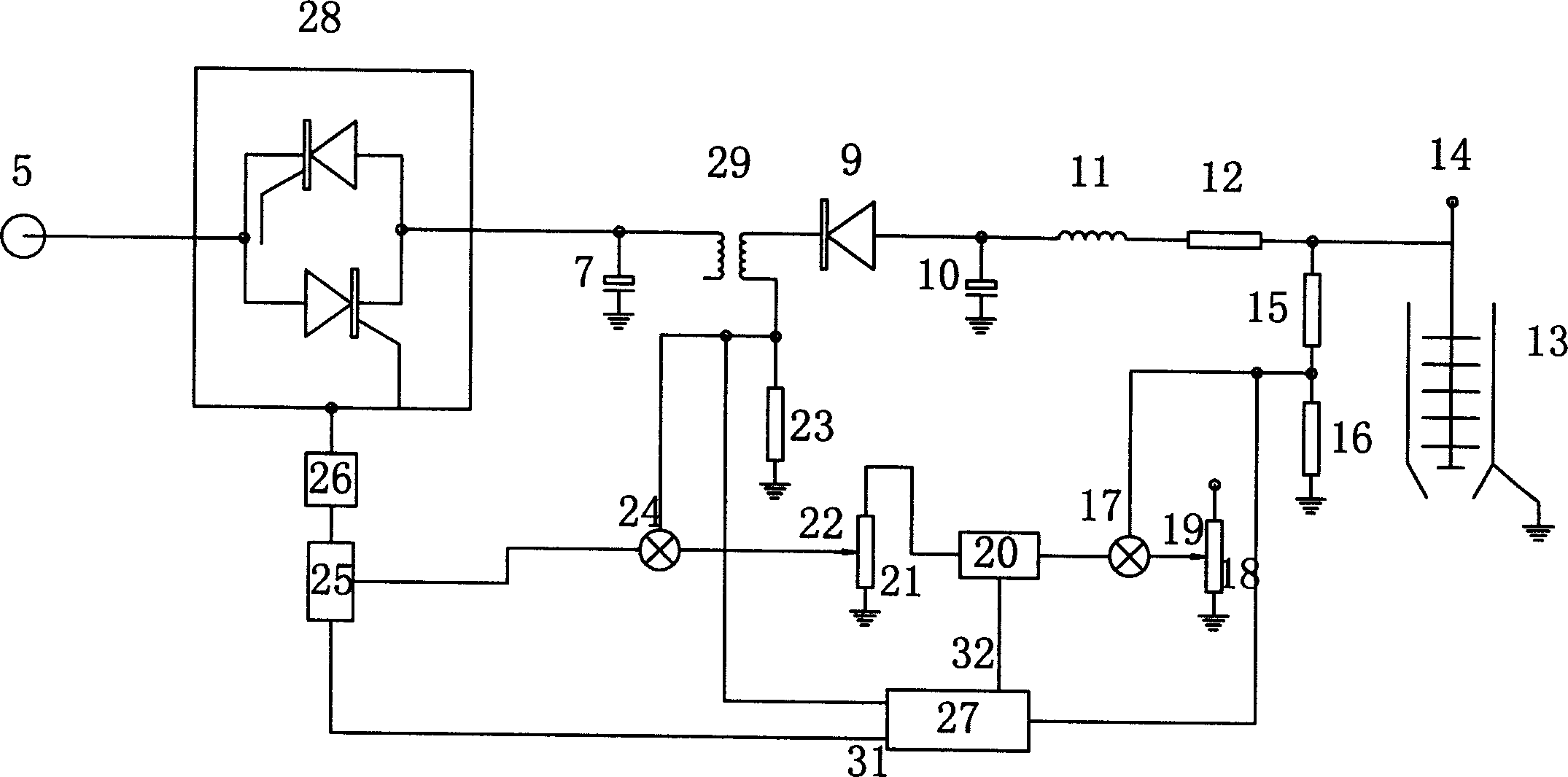

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] The output high voltage U of the power supply device used for electrostatic dust removal 0 and the output high voltage current I 0 , constructed as attached figure 1 shown in rectangular form. According to the site conditions, the high-voltage voltage line 1 is set at the required horizontal position to limit the maximum value of 36 (U 0M ), the maximum value is used to ensure that the emission reaches the standard, and the electrostatic precipitator electric field does not have a breakdown discharge. When it is necessary to automatically track and control the dust concentration, it is only necessary to adjust the control current 37 (I 0M ) to the left and right of the vertical line 2, it is enough to set the working point 3 of normal dust removal at the proper position on the vertical line 2.

[0020] Horizontal line 1 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com