Metal can recycling system

A recycling system and metal tank technology, applied in the direction of motion accessories, combustion methods, lighting and heating equipment, etc., can solve problems such as system vibration, damage to cutting blades, high risk of fire or explosion, etc., to improve crushing efficiency and improve efficiency , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

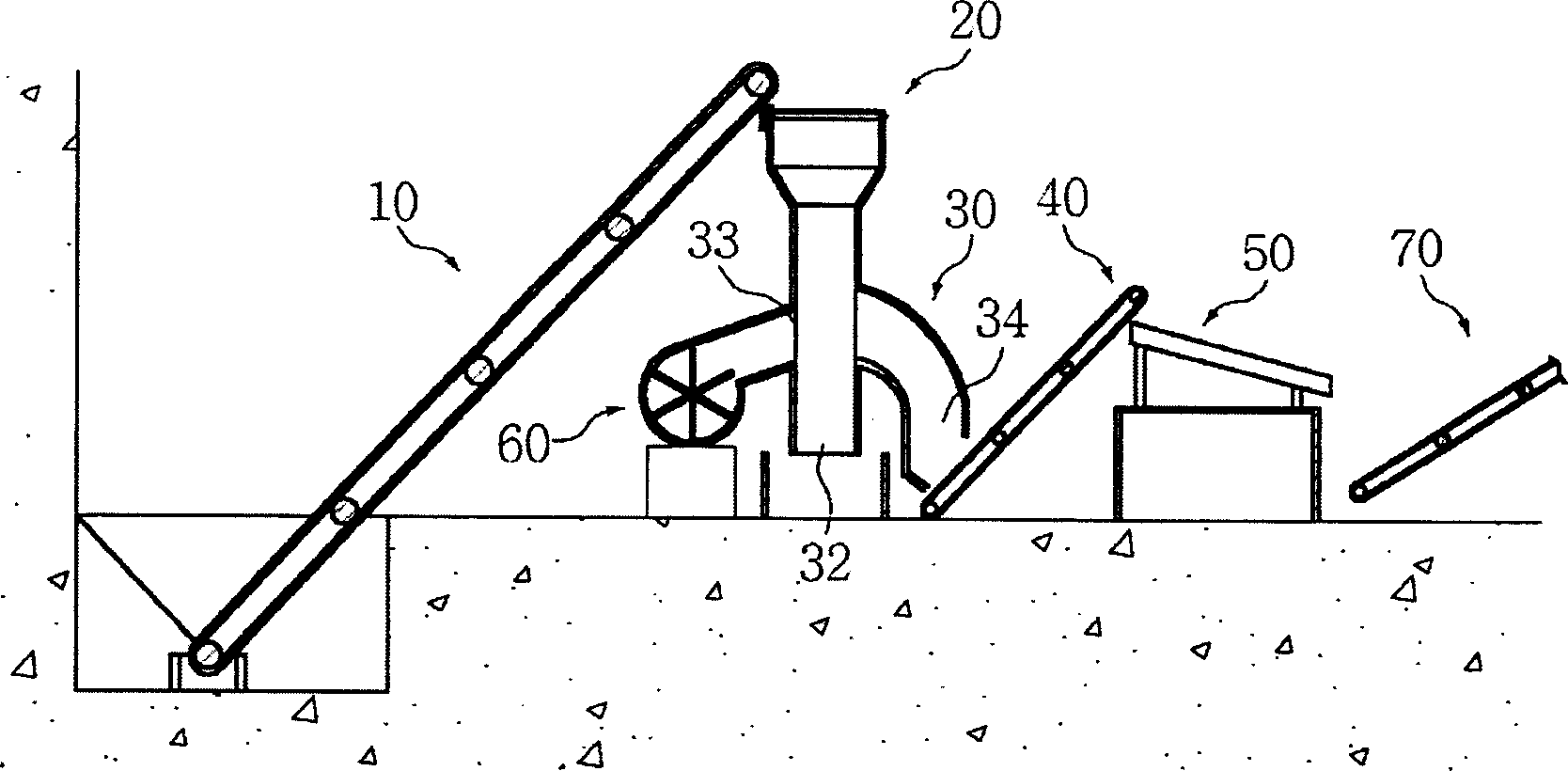

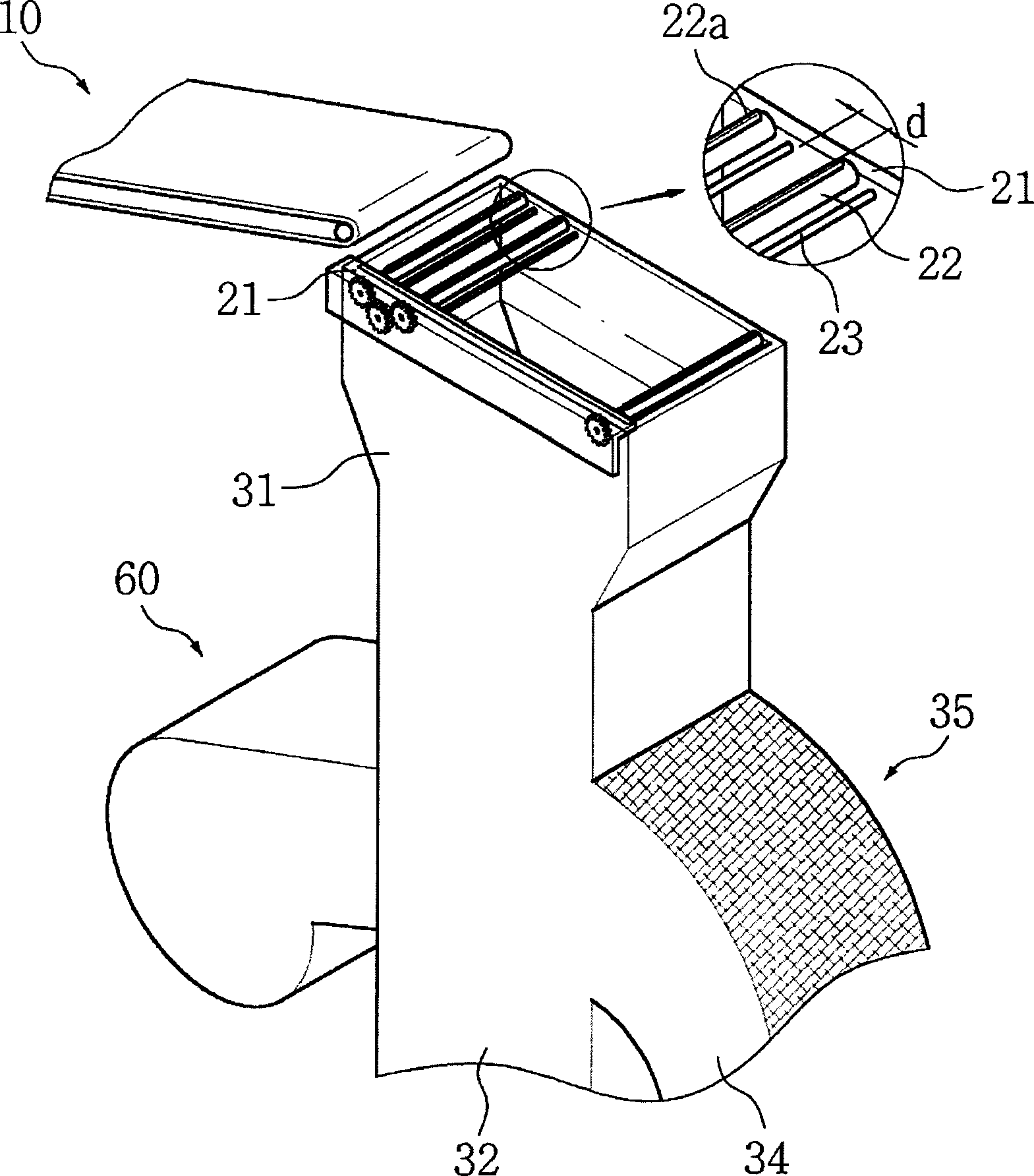

[0047] First refer to the following Figures 1 to 4 Explain the structure and operation of the can classification system.

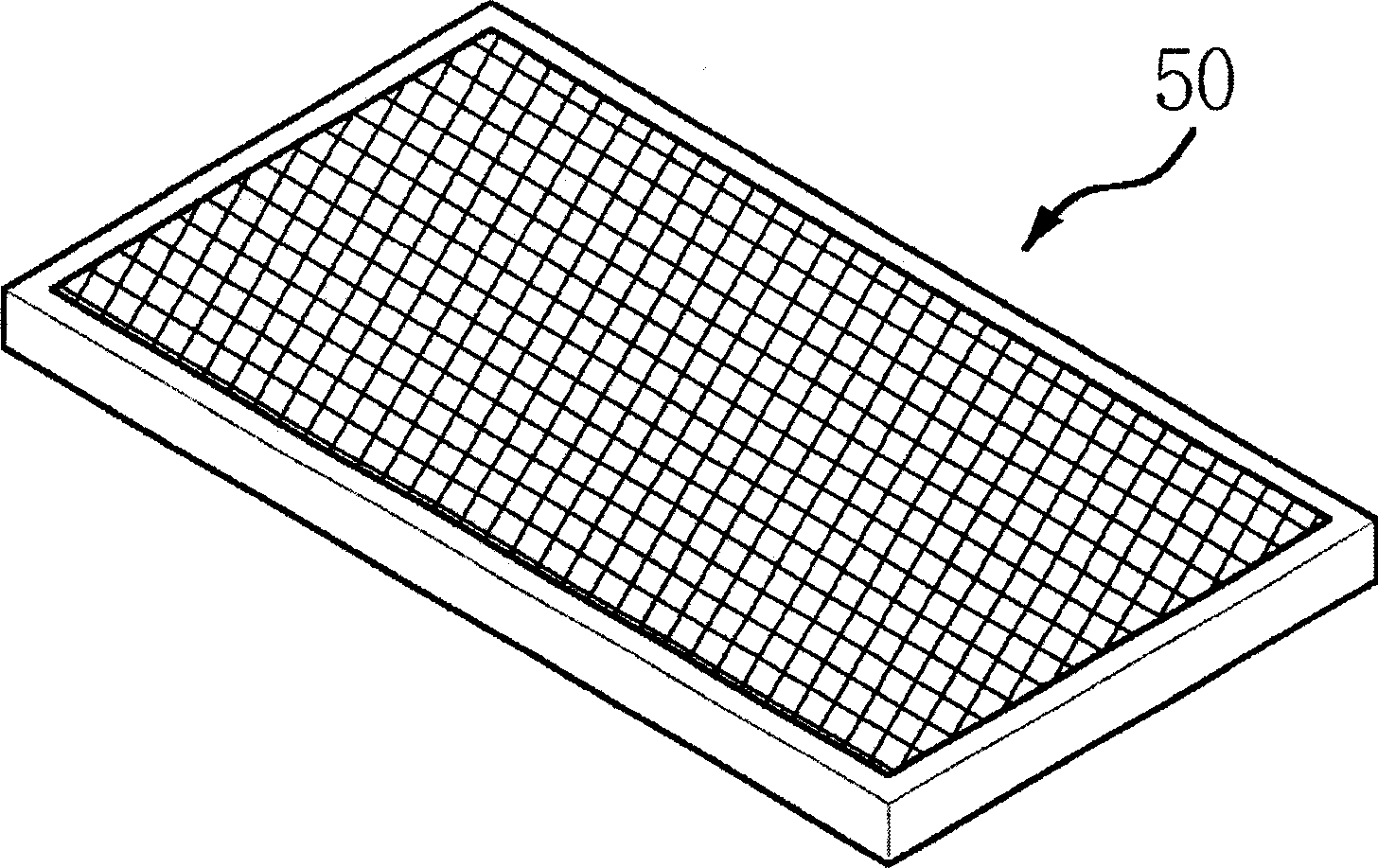

[0048] Said metal can sorting system comprises a first conveying device (10) for conveying the collected metal cans for reuse to a size sorting device (20); Sorting of recovered metal cans conveyed by the first conveying device (10); specific gravity sorting device (30) for separating metal species such as iron flakes and metal balls from the metal cans sorted by the size sorting device (20) by wind power other substances; the second conveying device (40) is used for conveying the metal cans separated from the metal-based other substances by the specific gravity classification device (30) to the vibration classification device (50); the vibration classification device (50) is used to make the first The metal cans conveyed by the second conveying device (40) are vibrated to remove other substances mixed in the metal cans, and then the metal cans are conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com