Balling device

A technology of pelletizing machine and roller, which is applied in the direction of extrusion granulation by die, granulation on endless conveyor belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

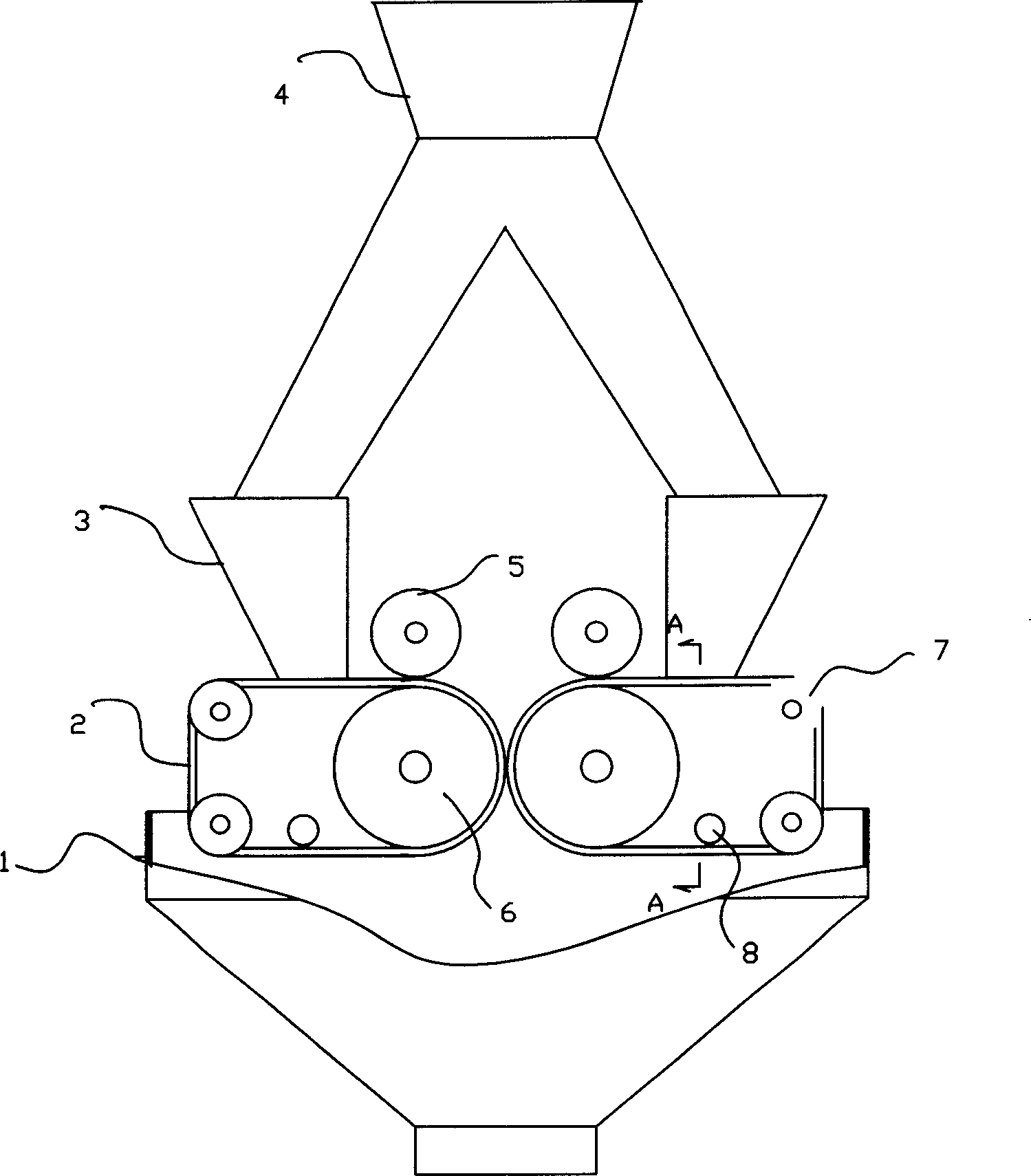

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

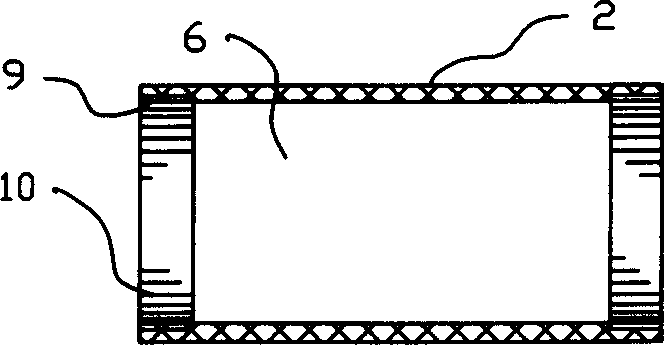

[0010] As can be seen from the accompanying drawings, the pelletizing machine of this program includes a feed bin (4) for supplying pellet powder and a cloth bin (3) for cloth, as well as a motor, A pair of rolls (6) driven by a speed reducer have a discharge chute (1) below the rolls (6). In this solution, there are elastic flexible templates (2) on the outer surfaces of the two rolls (6), and corresponding hemispherical dies are respectively arranged on the opposite faces of the two templates (2). The flexible template (2) is a strip template (2) wound on the roll (6) and the guide roll (7), and supported by the roll (6) and at least one guide roll (7). The specific embodiment adopted is supported by two belt guide rollers (7). There is also a nip roller (5) inside the two cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com