Standing wave frequency change step ultrasonic electric machine

An ultrasonic motor and stepping technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems such as difficult to increase torque and increase sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

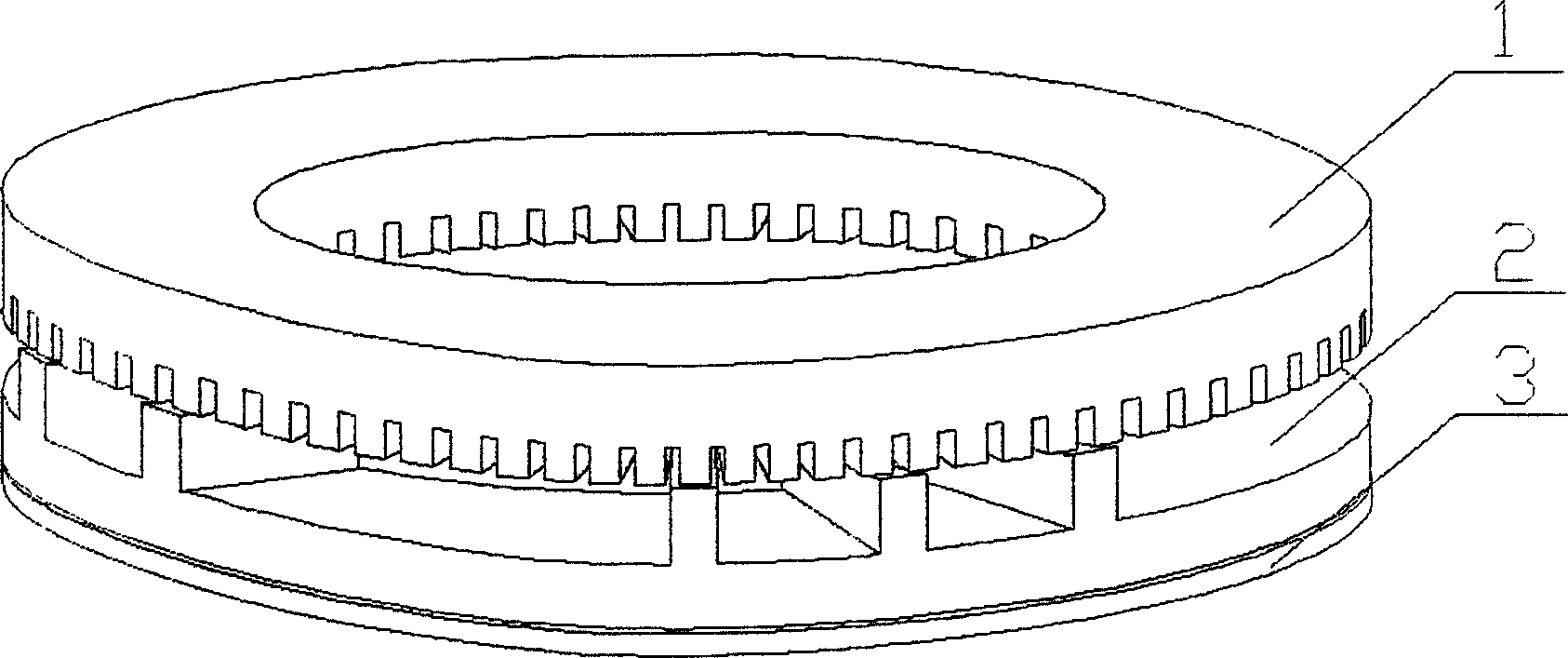

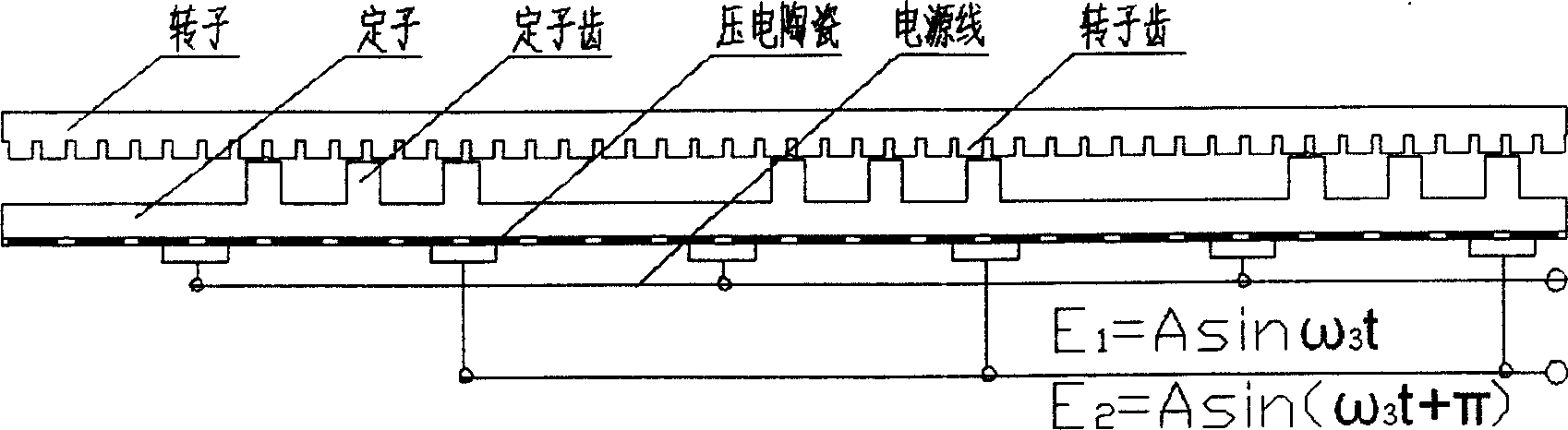

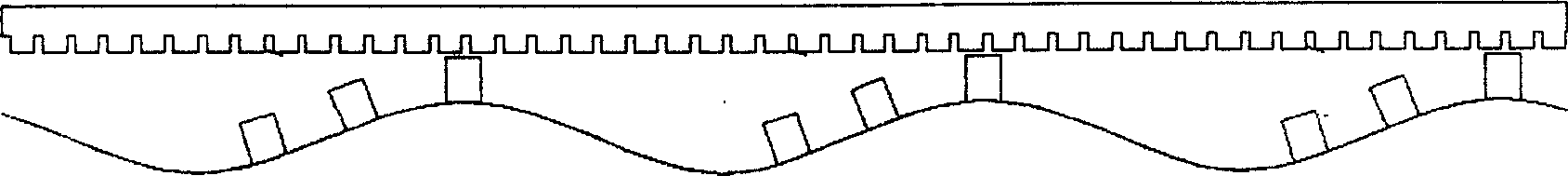

[0012] Standing wave frequency conversion stepping ultrasonic motor such as figure 1. shown. Its characteristics: the stator 2 is composed of an elastic body with convex teeth on the upper end surface and uniformly partitioned axially polarized piezoelectric ceramic rings 3 on the lower end surface; the annular rotor 1 with evenly graduated tooth grooves on the lower end surface is pressed on the stator 2 on the convex teeth; the piezoelectric ceramic ring excites the bending vibration of the stator elastic body, and the oblique movement of several stator convex teeth acts on the rotor tooth surface to generate circumferential thrust and drive the rotor to move; when the rotor turns over the rotor teeth When half the tooth pitch of the stator, the driving teeth corresponding to this vibration mode of the stator are respectively located at the slots of the rotor, the rotor cannot be driven, and the first step of the rotor motion ends; when the power is switched to excite the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com