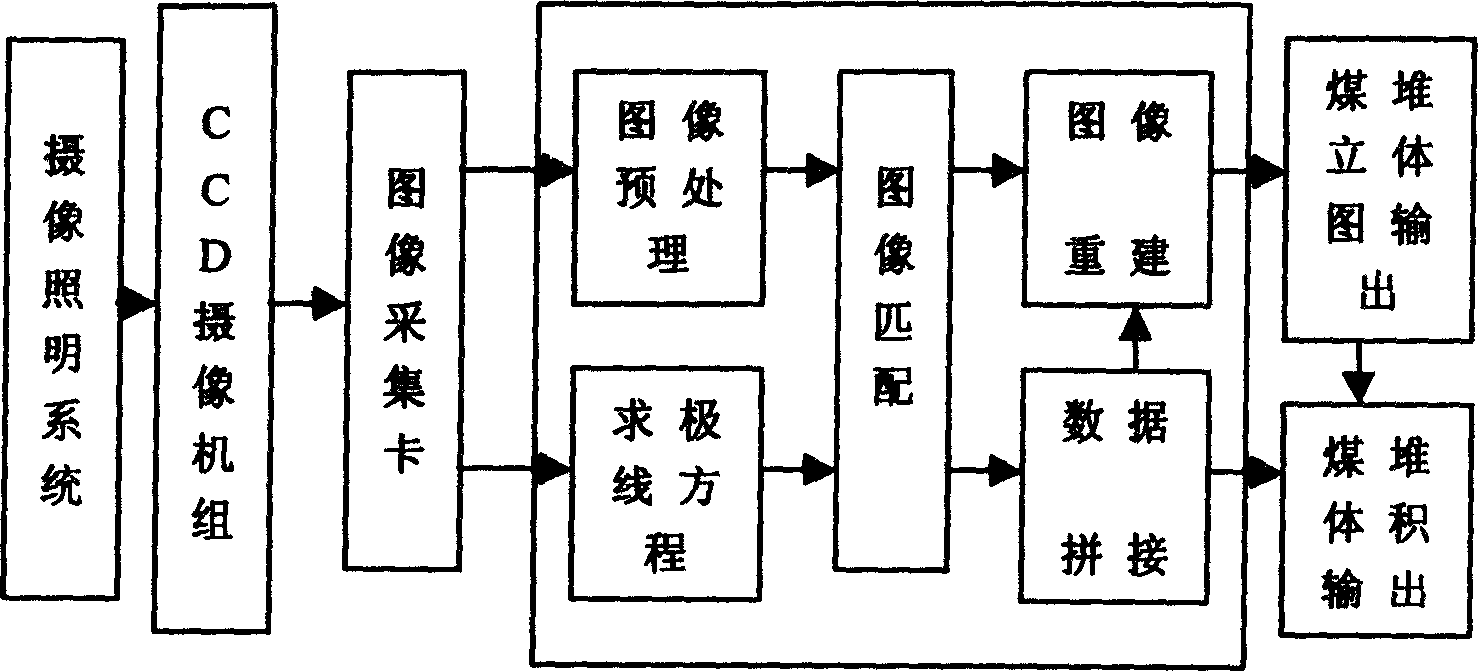

Method for testing storage quantity of coal through stereoscopic vision

A technology of stereo vision and pan coal, applied in the field of stereo vision pan coal, can solve the problems of high equipment cost and long measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

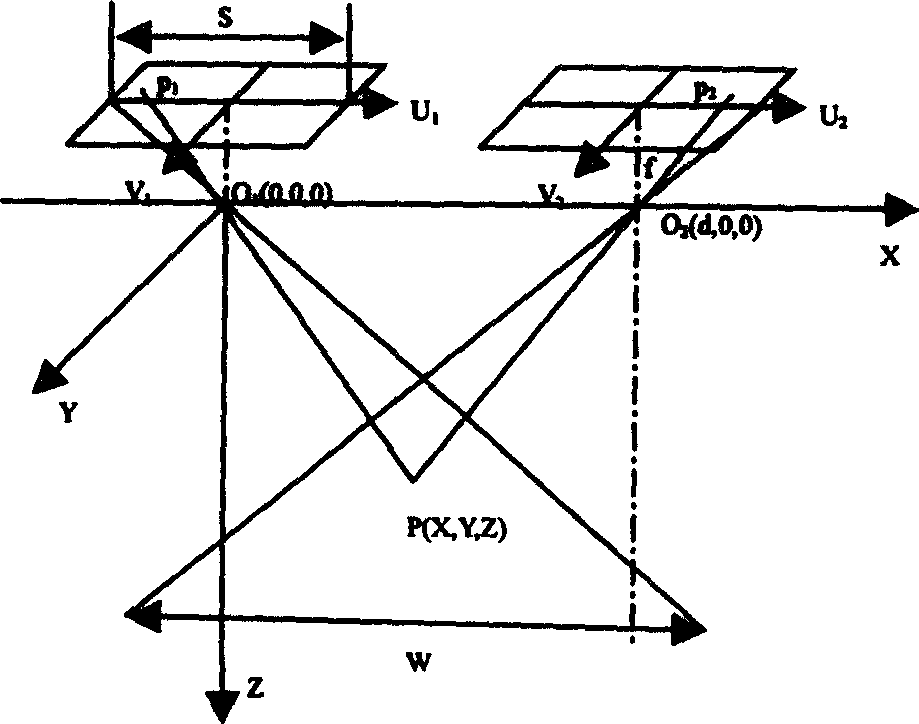

[0032] A stereoscopic vision coal pan method for measuring coal storage in coal yards:

[0033] (1) Install a pair of cameras above the coal pile, adjust the cameras so that the optical axis of the cameras is perpendicular to the optical platform, and measure the distance Z between the optical center of the camera and the optical platform, take the point on the optical platform as a reference point, and use the camera to align It shoots and gets a set of points ((u 1 , v 1 ), (u 2 , v 2 ),......,(u n , v n )); then, move the camera for a distance d along the optical axis, and then shoot the optical platform to obtain the second set of points ((u 1 ’, v 1 ’), (u 2 ’, v 2 ’), ......, (u n ’, v n ’)), using the formula

[0034] Q ( u 1 ′ + k 1 ( u 1 ...

Embodiment 2

[0055] This embodiment adopts the following steps:

[0056] (1) Camera calibration: determine the relationship between the world coordinate system, camera coordinate system, and image coordinate system

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com