Steam compression type refrigeration cycle device of approximate ideal inverse Carnot cycle efficiency

A technology of reverse Carnot cycle and refrigeration cycle, applied in the field of vapor compression refrigeration cycle device, can solve the problems of large heat load of compressor and low cycle energy efficiency, and achieve the effect of small change in thermal perfection and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

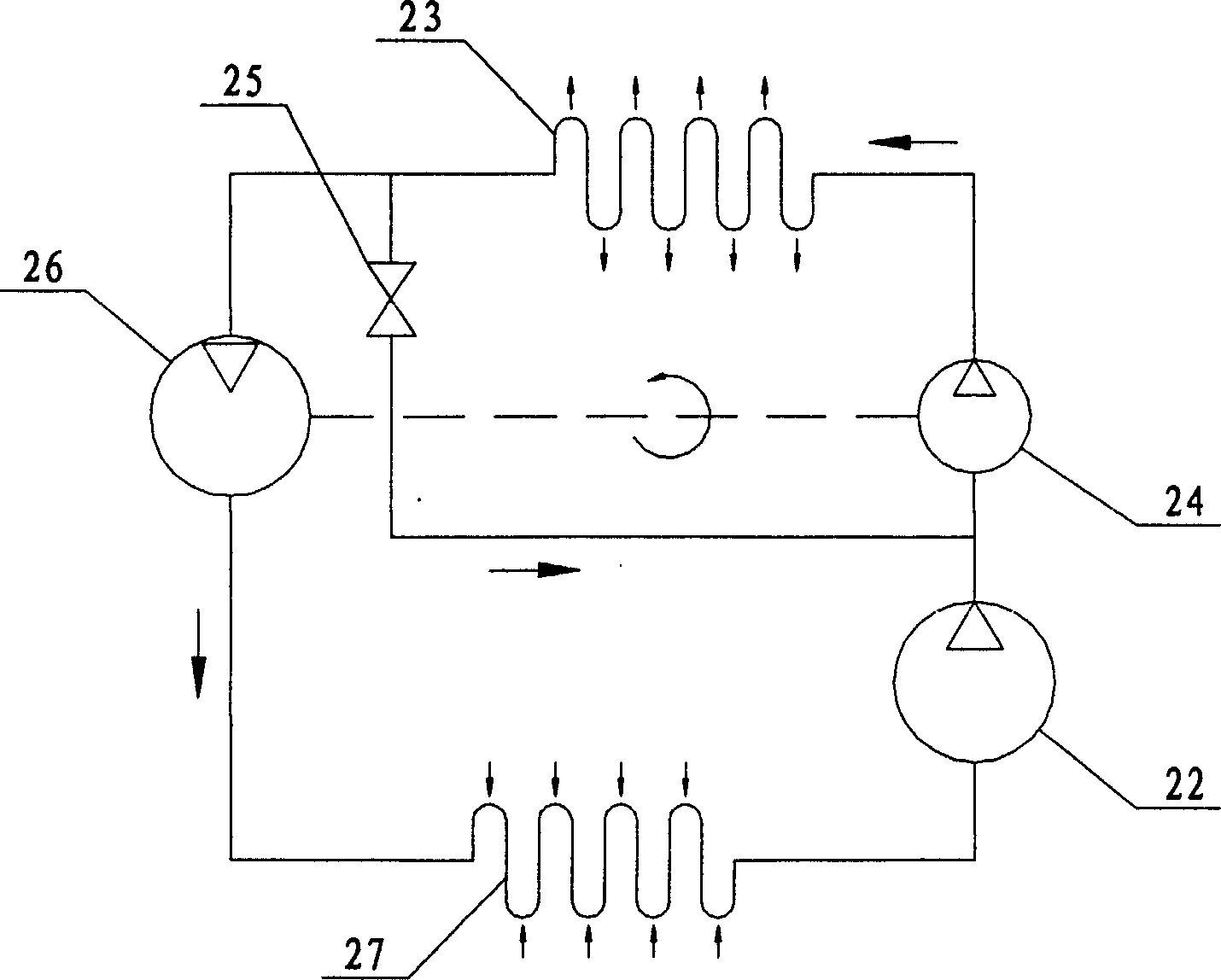

[0029] Vapor compression refrigeration cycle device of the present invention such as figure 2 As shown, the outlet of the compressor 22 is connected to the inlet of the booster pump 24 after being connected in parallel with the outlet of the restrictor 25 . After the inlet of the expansion motor 26 is connected in parallel with the inlet of the restrictor 25, it is connected to the outlet of the condenser 23. The inlet of the evaporator 27 is connected to the outlet of the expansion motor 26 , and the outlet of the evaporator 27 is connected to the inlet of the compressor 22 . The outlet of the booster pump 24 is connected to the inlet of the condenser 23 . The expansion motor 26 is coaxially connected to the booster pump 24 .

[0030] In the refrigeration cycle of the present invention, the isentropic expansion of the expansion motor 26 greatly reduces the enthalpy of the working fluid entering the condenser; the use of the booster pump 24 makes the operating pressure diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com