Processing method of Lingtou Dancong Tea

A processing method and technology of single pine tea, applied in the direction of tea treatment before extraction, can solve the problems of low quality rate of products, lack of scientific and systematic tea-making technology, etc. The effect of low environmental requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

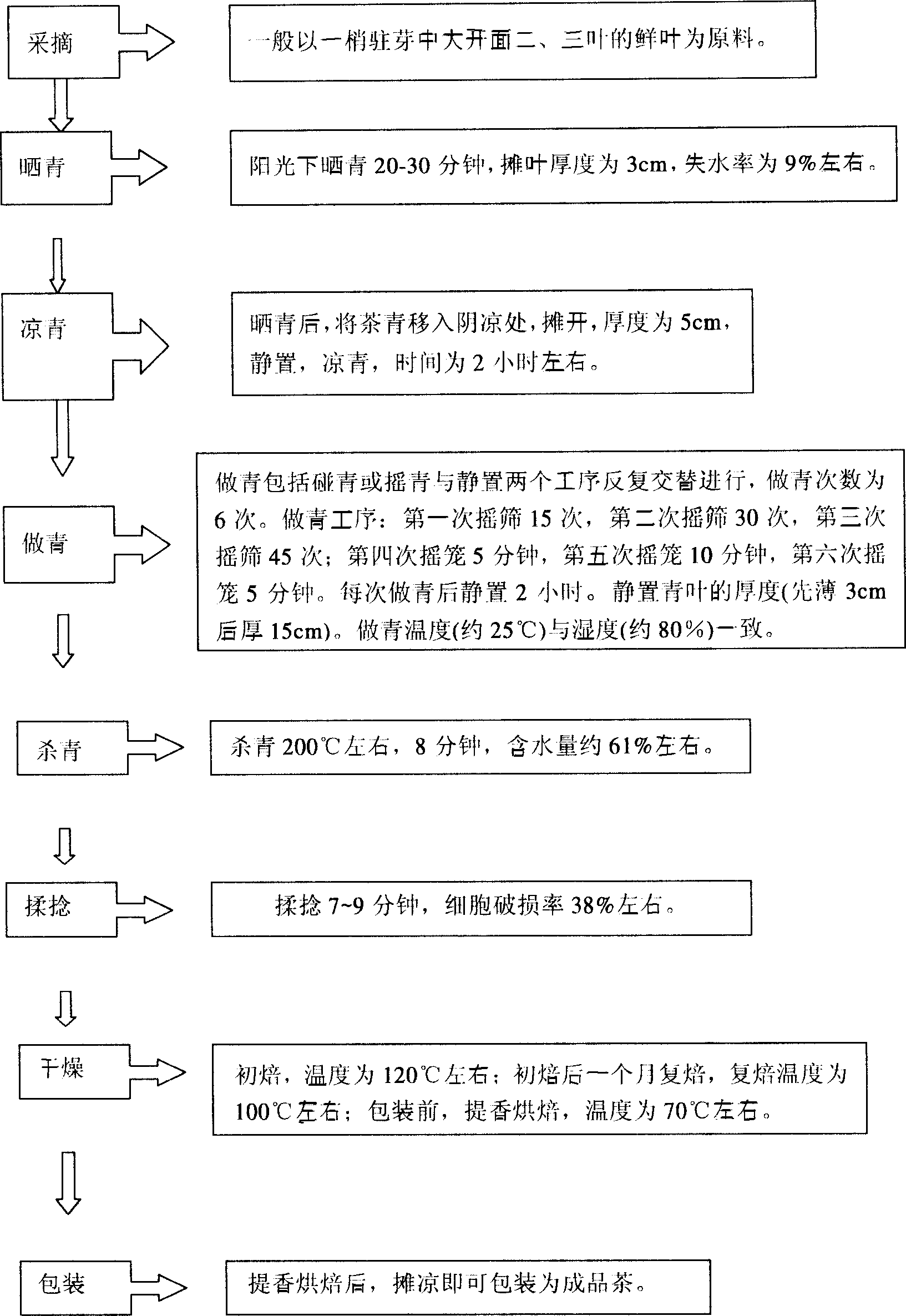

[0032] (1), picking fresh leaves: pick 500kg of fresh leaves of Lingtou Dancong tea, generally pick the fresh leaves with two or three leaves in the middle of a tip bud;

[0033] (2), sun drying: after the fresh leaves are plucked, they are dried on a special cement site for 25 minutes, and the leaf thickness is 3cm;

[0034] (3), cool green: after drying the green tea, immediately move the tea green into a cool place (be careful not to use too much force, so as not to damage the tea green), and then spread it out. The thickness of the tea leaves is preferably about 5cm. 2 hours;

[0035] (4), making green: including bumping green or shaking green and standing two processes and carrying out alternately alternately, the number of times of making green is 6 times, and concrete procedure is: shake sieve for the first time 15 times, shake sieve for the second time 30 times, Shaking 45 times for the third time, shaking the cage for 5 minutes for the fourth time, 10 minutes for the...

Embodiment 2

[0041] (1), picking fresh leaves: pick 500kg of fresh leaves of Lingtou Dancong tea, generally pick the fresh leaves with two or three leaves in the middle of a tip bud;

[0042] (2), sun drying: after the fresh leaves are plucked, they are dried on a special cement site for 30 minutes, and the leaf thickness is 3cm;

[0043] (3), cool green: after drying the green tea, immediately move the tea green into a cool place (be careful not to use too much force, so as not to damage the tea green), and then spread it out. The thickness of the tea leaves should be about 6cm. 2 hours;

[0044] (4), making green: including bumping green or shaking green and standing two processes alternately repeatedly, the number of times of making green is 7 times, respectively: shake 15 times for the first time, shake sieve for the second time 30 times, shake the sieve for the second time Shake 45 times for three times, shake the cage for 4 minutes for the fourth time, 9 minutes for the fifth time, ...

Embodiment 3

[0050] (1), picking fresh leaves: pick 500kg of fresh leaves of Lingtou Dancong tea, generally pick the fresh leaves with two or three leaves in the middle of a tip bud;

[0051] (2), sun drying: after the fresh leaves are plucked, they are dried on a special cement site for 20 minutes, and the leaf thickness is 3cm;

[0052] (3), cool green: after drying the green tea, immediately move the tea green into a cool place (be careful not to use too much force, so as not to damage the tea green), and then spread it out. The thickness of the tea leaves is preferably about 5cm. 2 hours;

[0053](4), greening: including bumping greens or shaking greens and standing two processes alternately and repeatedly, and the number of times of making greens is 6 times. Greening process: shake 14 times for the first time, 28 times for the second time, 48 times for the third time, 6 minutes for the fourth time, 8 minutes for the fifth time, 7 times for the sixth time minute. Stand still for 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com