Method of producing laminated type organic electroluminescent element and display apparatus

An electroluminescent element and a manufacturing method technology, which can be applied to electroluminescent light sources, electrical components, devices for coating liquid on surfaces, etc., can solve problems such as low production efficiency, and achieve low power consumption, low price, and durability. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The method for manufacturing the multilayer organic EL element and the display device of the present invention will be described in detail below.

[0049] 1) Manufacturing method of multilayer organic EL element

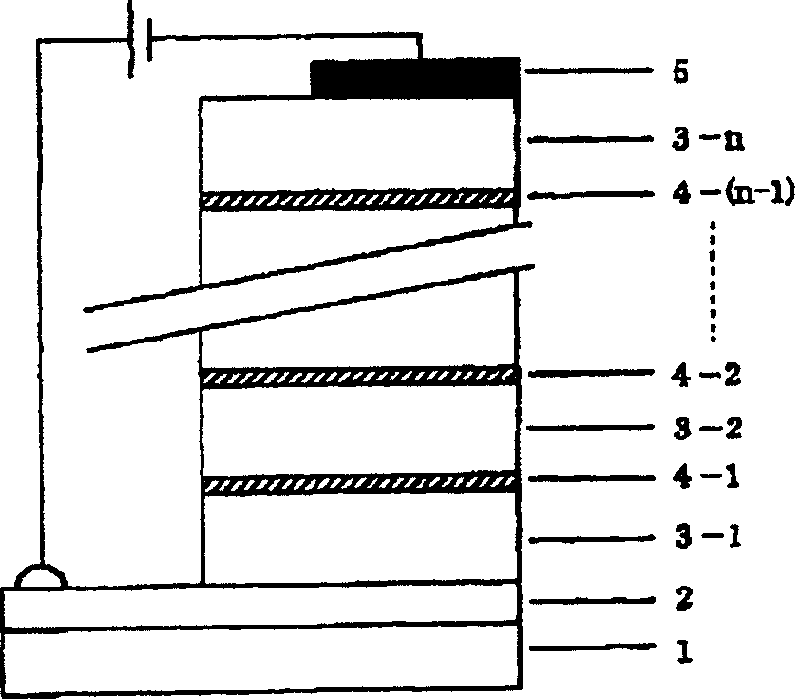

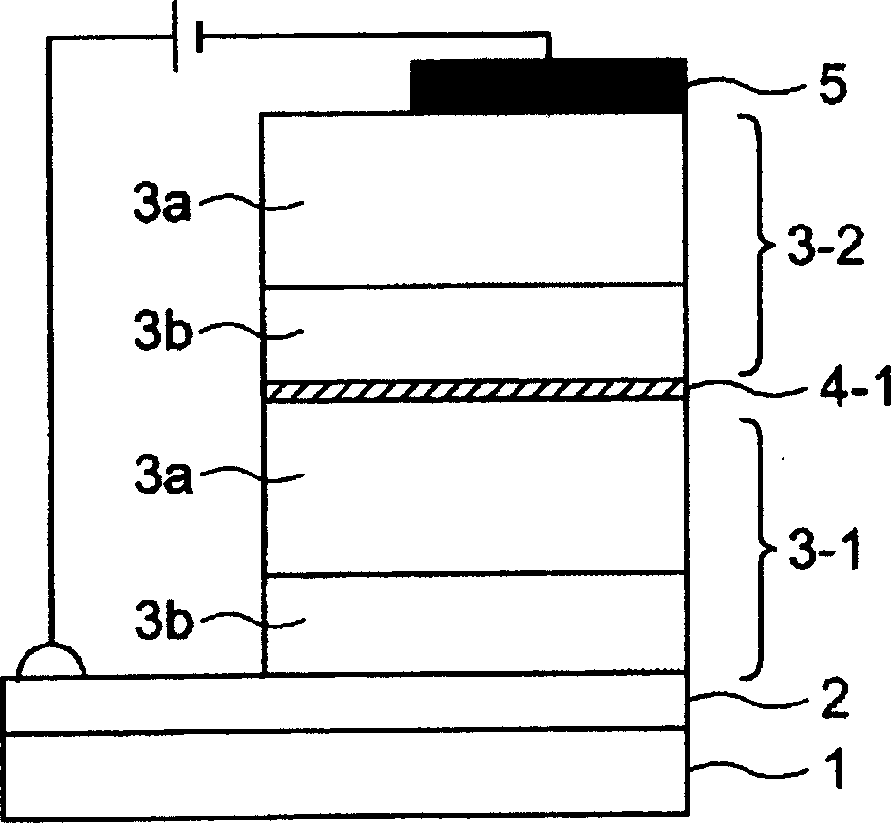

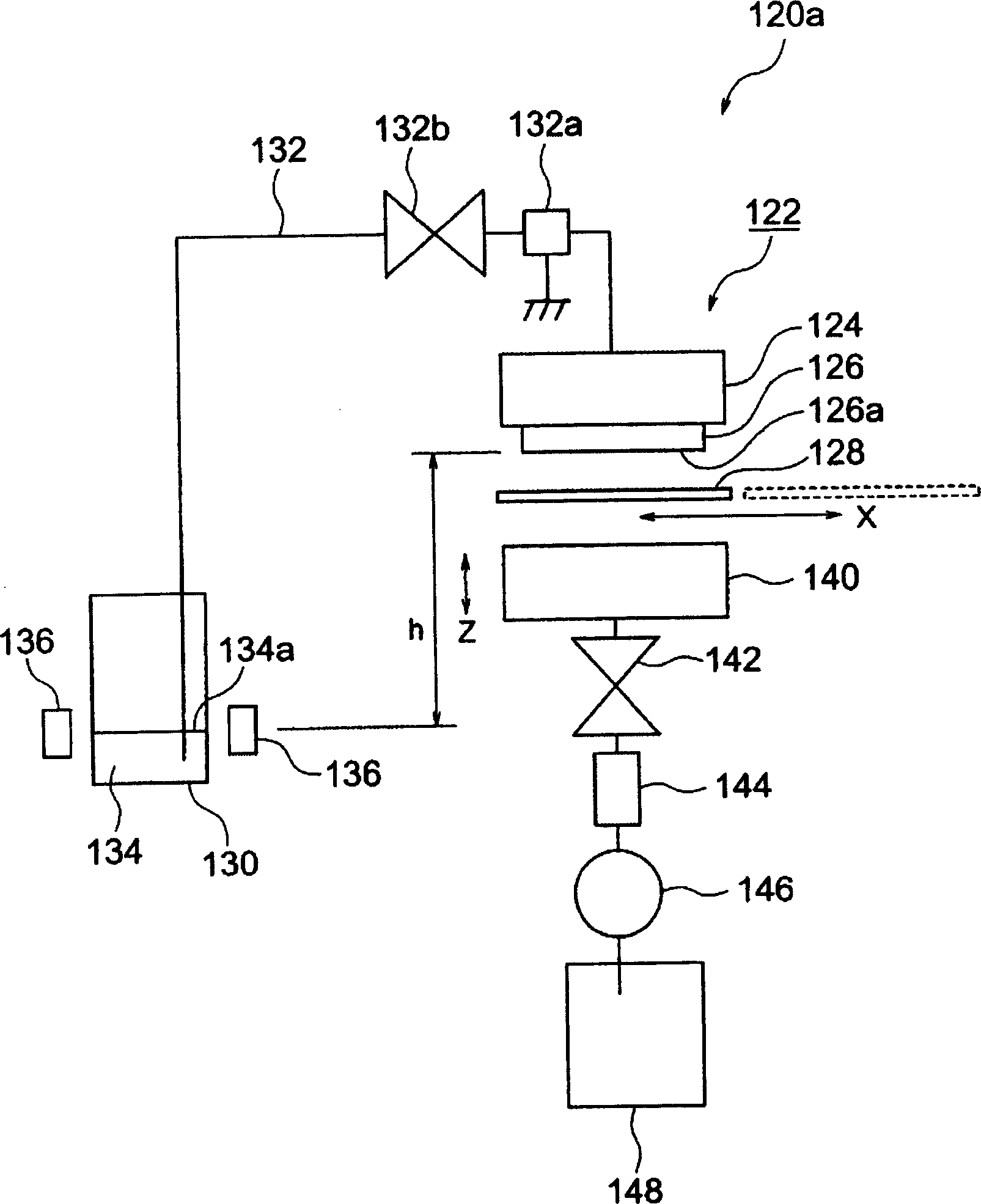

[0050] The manufacturing method of the laminated organic EL element of the present invention comprises at least one light-emitting layer between the opposing transparent anode electrodes and cathode electrodes, and has a plurality of light-emitting units divided by at least one charge generation layer. A method of manufacturing a stacked organic electroluminescent device, wherein at least one of the charge generation layers is formed using a discharge device.

[0051] In the present invention, the "light-emitting unit" means a layered structure including at least one light-emitting layer, and among the constituent elements of a conventional organic EL element, other than the anode electrode and the cathode electrode. Examples of the "light-emitting unit" incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com