Sewing machine with faulty thread mark detection device

A detection device and sewing machine technology, applied in the field of sewing machines, can solve problems such as inaccuracy and unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

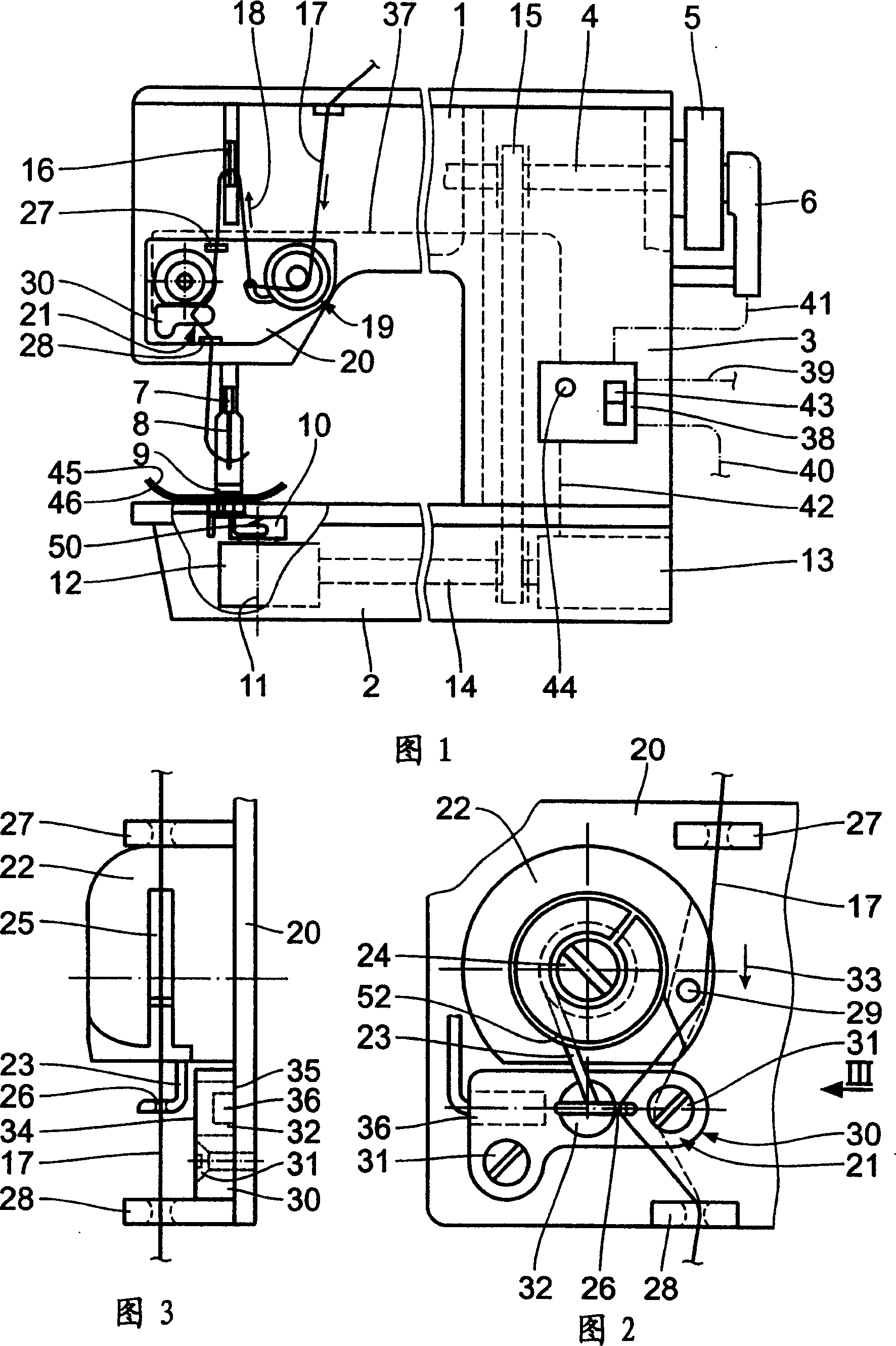

[0014] As shown in FIG. 1, a sewing machine generally includes a top arm 1, a shell-shaped base plate 2, and a column 3 connected to the top arm 1 and the base plate 2 at its two ends, so that the sewing machine becomes a C-shape. An arm shaft 4 is located in the top arm 1, and the end of the arm shaft 4 outside the top arm 1 supports a handwheel 5, and a momentum transmission device 6 is installed on the arm shaft 4 next to the handwheel 5. The actuation of the needle bar 7 with a needle 8 and a presser foot 9 usually comes from the arm shaft 4 .

[0015] A vertical hook / shuttle 10 is located within the base plate 2 for rotation about a vertical axis 11 of the hook support 12 . The wire hook 10 is actuated via a wire hook drive shaft 14 by a drive motor 13 arranged in the base plate 2 below the column 3 . The hook drive shaft 14 also actuates the arm shaft 4 via a belt drive 15 .

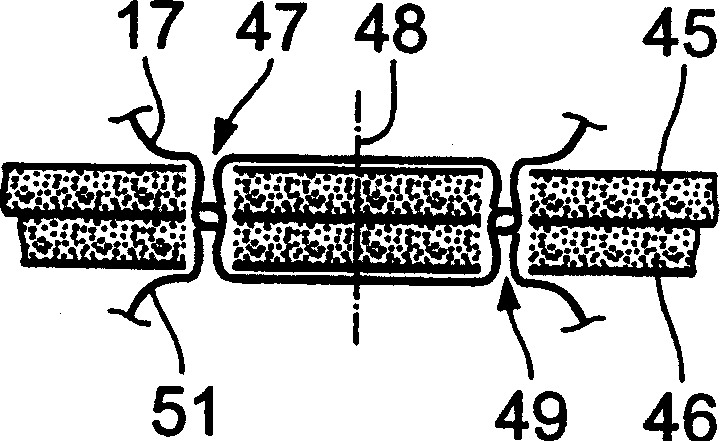

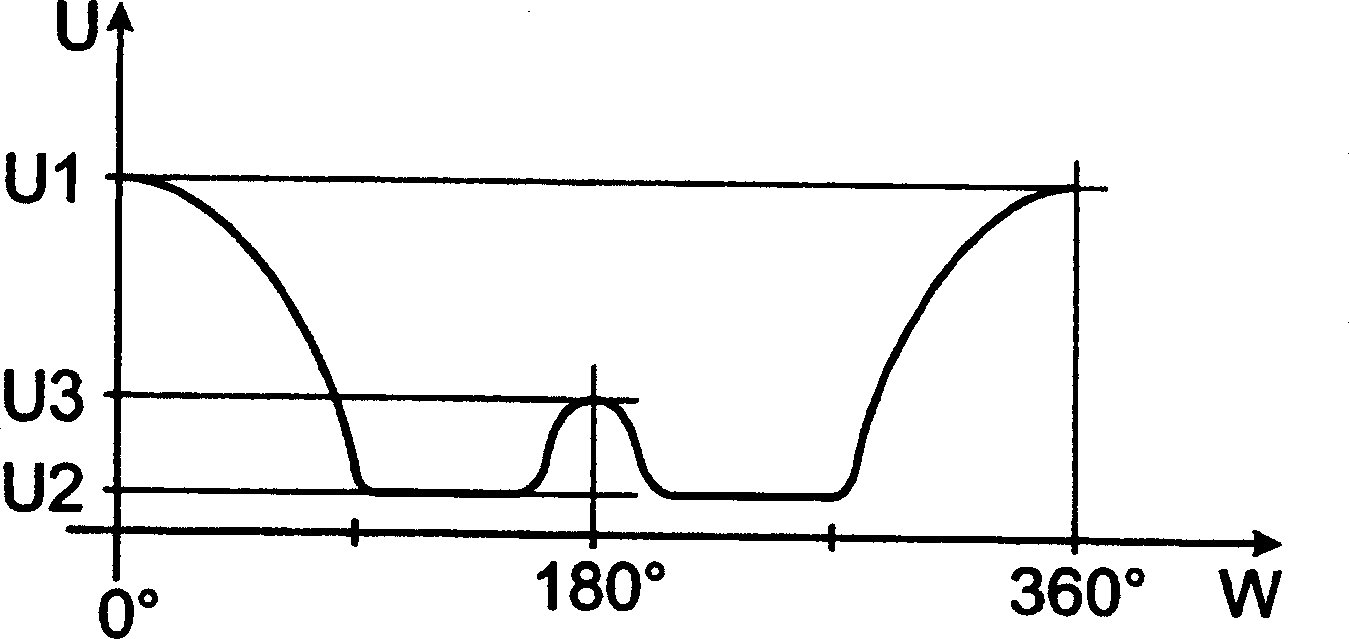

[0016] The top arm 1 also holds a thread take-up lever 16 for a needle thread 17 also driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com