Linear vibration motor using resonance frequency

A technology of linear vibration and resonant frequency, which is applied in the direction of vibrating fluids, shock absorbers, electric components, etc., can solve the problems of shortening the life of the motor, not being able to maximize the amplitude of the fixed volume, and not being able to maximize the quality of the vibrator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

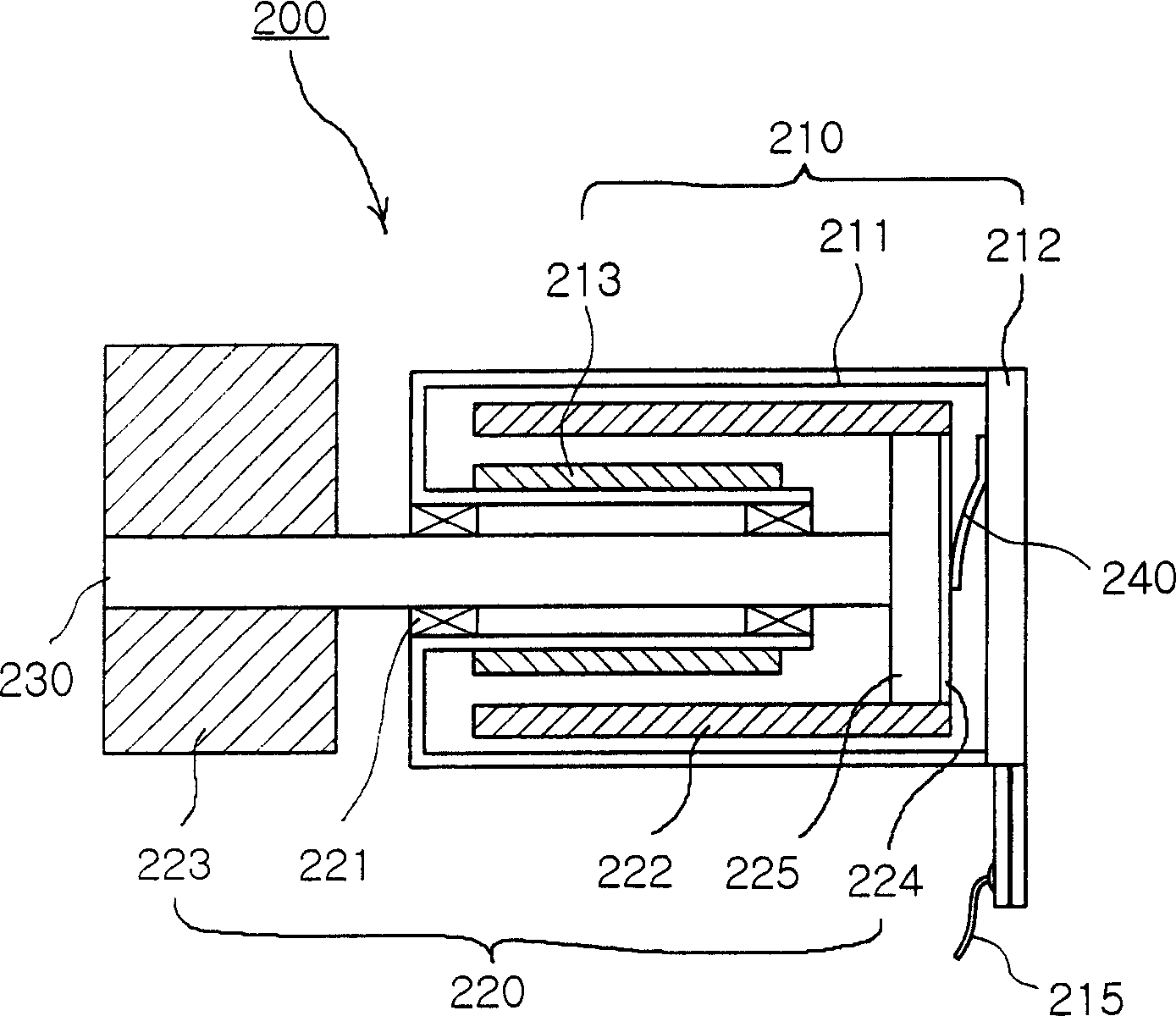

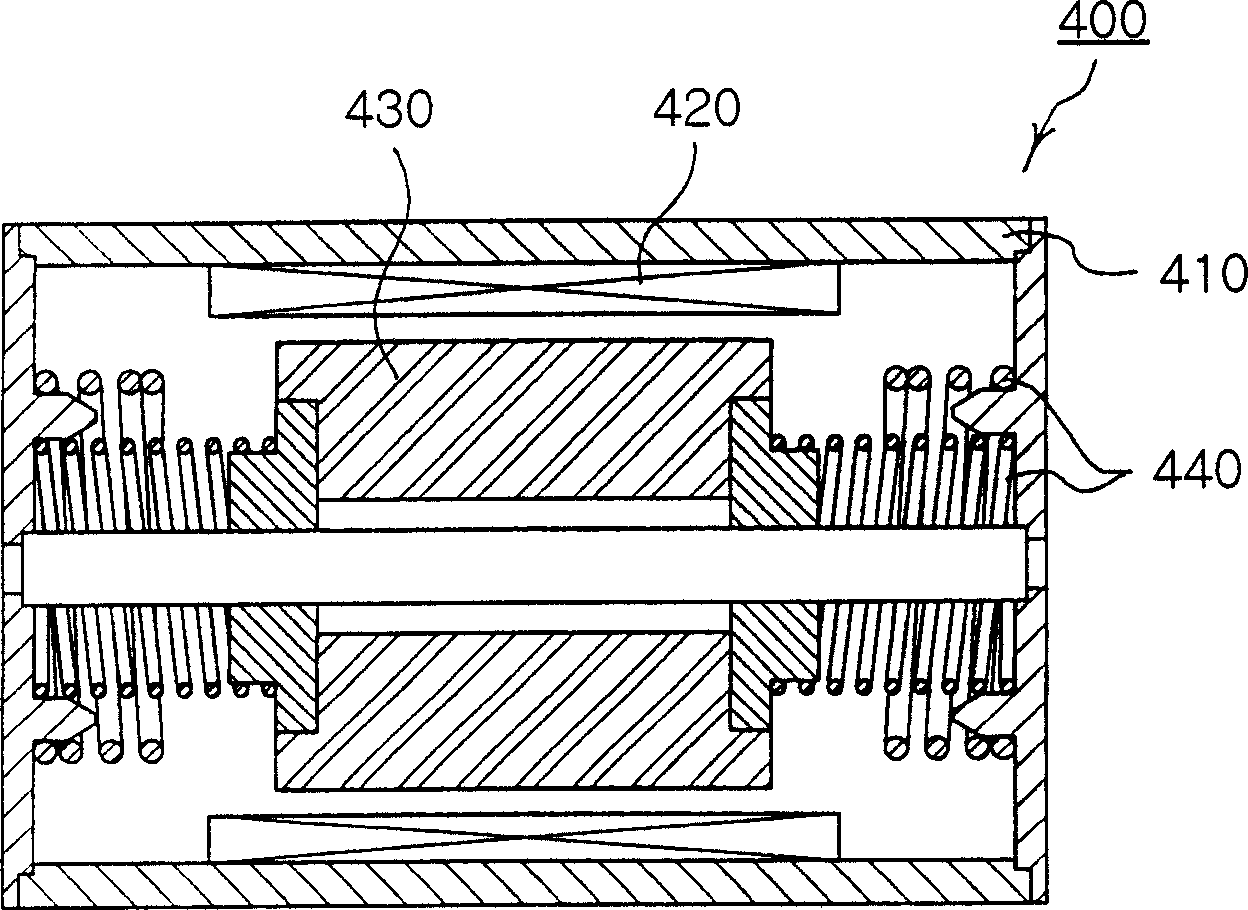

[0048] Figure 4 and 5 A linear vibration motor using the resonant frequency of the present invention, which will be described below, is exemplified.

[0049] The present invention pertains to linear vibrating motors, vibrations are obtained by the interaction of magnetic force from a magnet and electromagnetic force of a specific frequency from a coil assembly, by using vertical resonance of a movable unit, and generally includes a movable unit 20, a base assembly 40 and housing 10 .

[0050] The movable unit 20 has a magnet 21 , a yoke 22 for accommodating the magnet 21 , and a weight 23 of a certain mass surrounding the side of the yoke 22 . The weight 23 preferably has a specific gravity greater than that of iron. Therefore, this increases the mass of the fixed volume movable unit to adjust the resonant frequency in relation to the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com