Heat treatment equipment and method for reflection film

A heat treatment device and heat treatment method technology, applied in projection devices, image reproducers using projection devices, picture replicators, etc., can solve the problems of fine wrinkles, low image quality, wrinkles, etc., so as to reduce labor and avoid difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in further detail: the specific example of the present invention is prompted in detail below, hope, the party that understands thought of the present invention, do not be limited to the example that prompts thought of the present invention, in the thought category of the present invention Within, examples that are both simple and different can be presented.

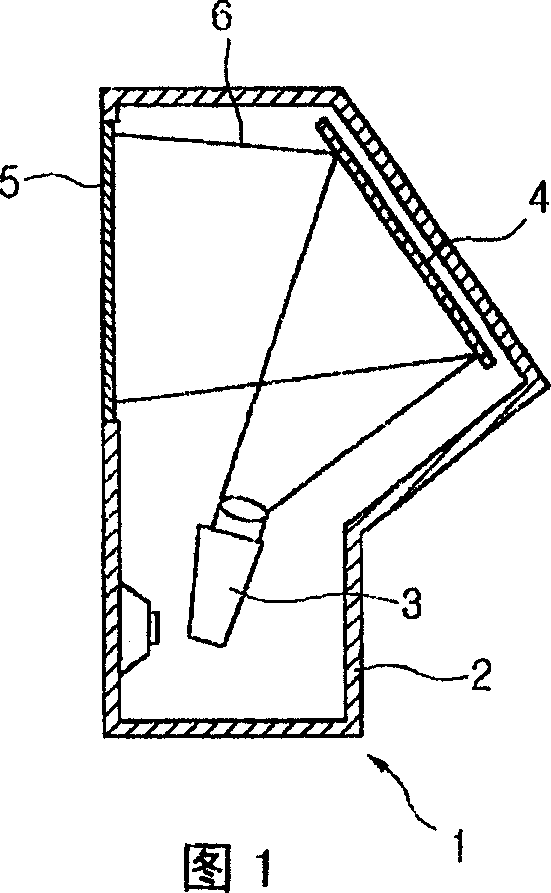

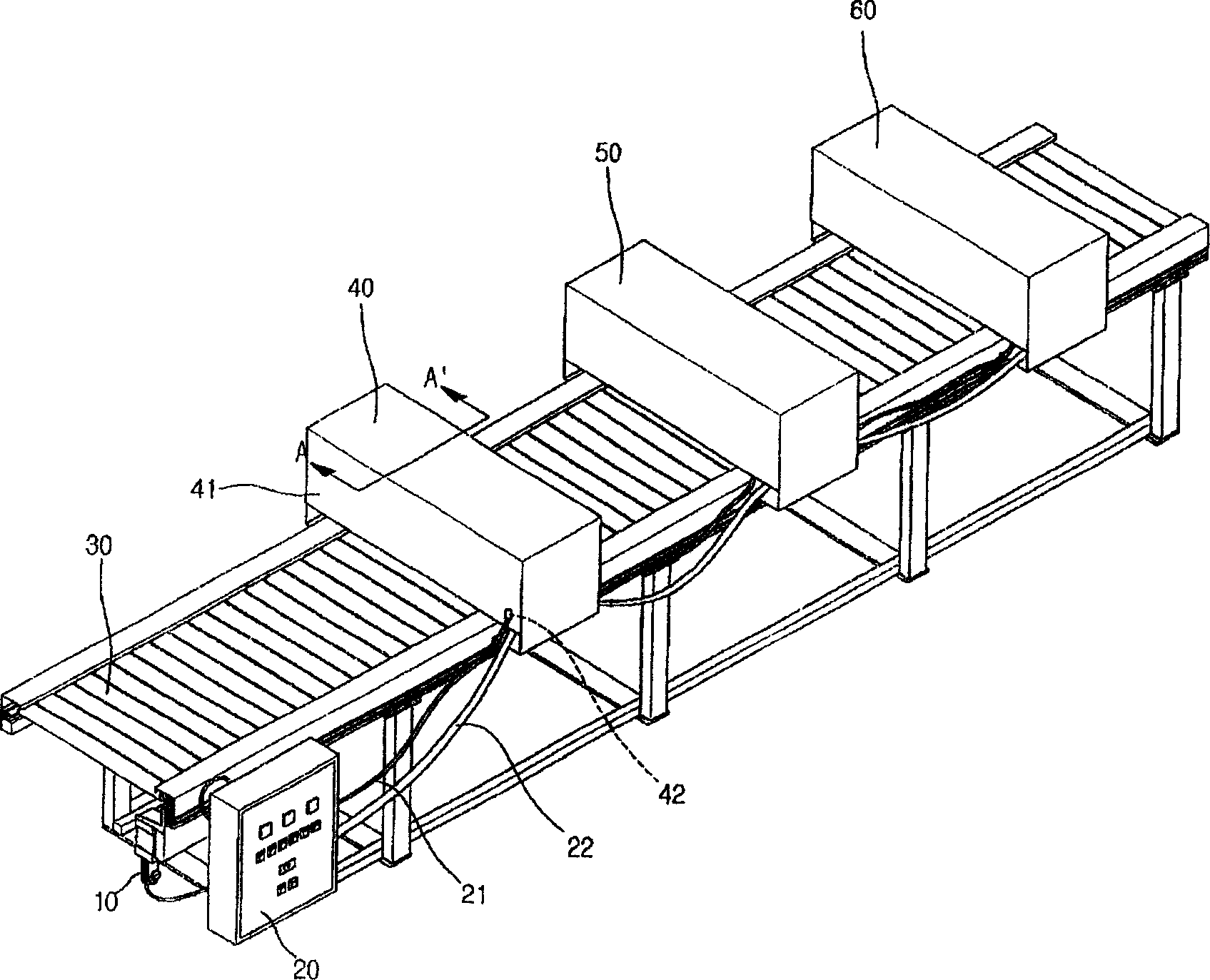

[0041] image 3 Yes, the schematic front view of the reflective film heat treatment device of the present invention.

[0042] refer to image 3 It can be seen that the reflective film heat treatment device of the present invention is composed of: at least equipped with a heating element, i.e. a heating part (40) (50) (60) of a heater; and an operating panel (20) for controlling the above-mentioned heating part; and The operation panel (20) is connected and supplies the external power to the power line a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com