Plane display with touching function and its forming method

A flat-panel display and display element technology, applied in static indicators, instruments, electrical components, etc., can solve problems such as affecting the life and quality of display panels, difficult to balance display quality and touch performance, and lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

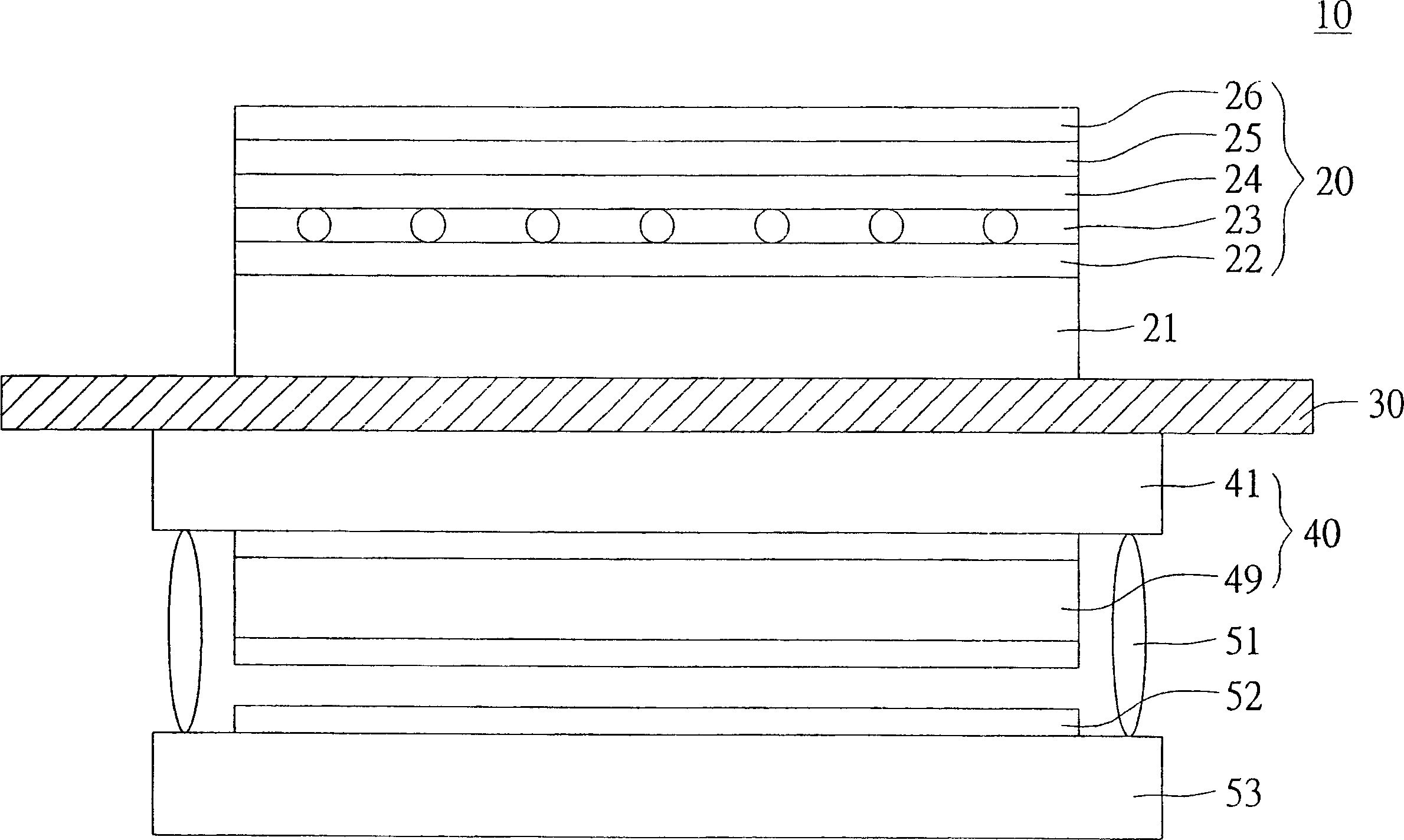

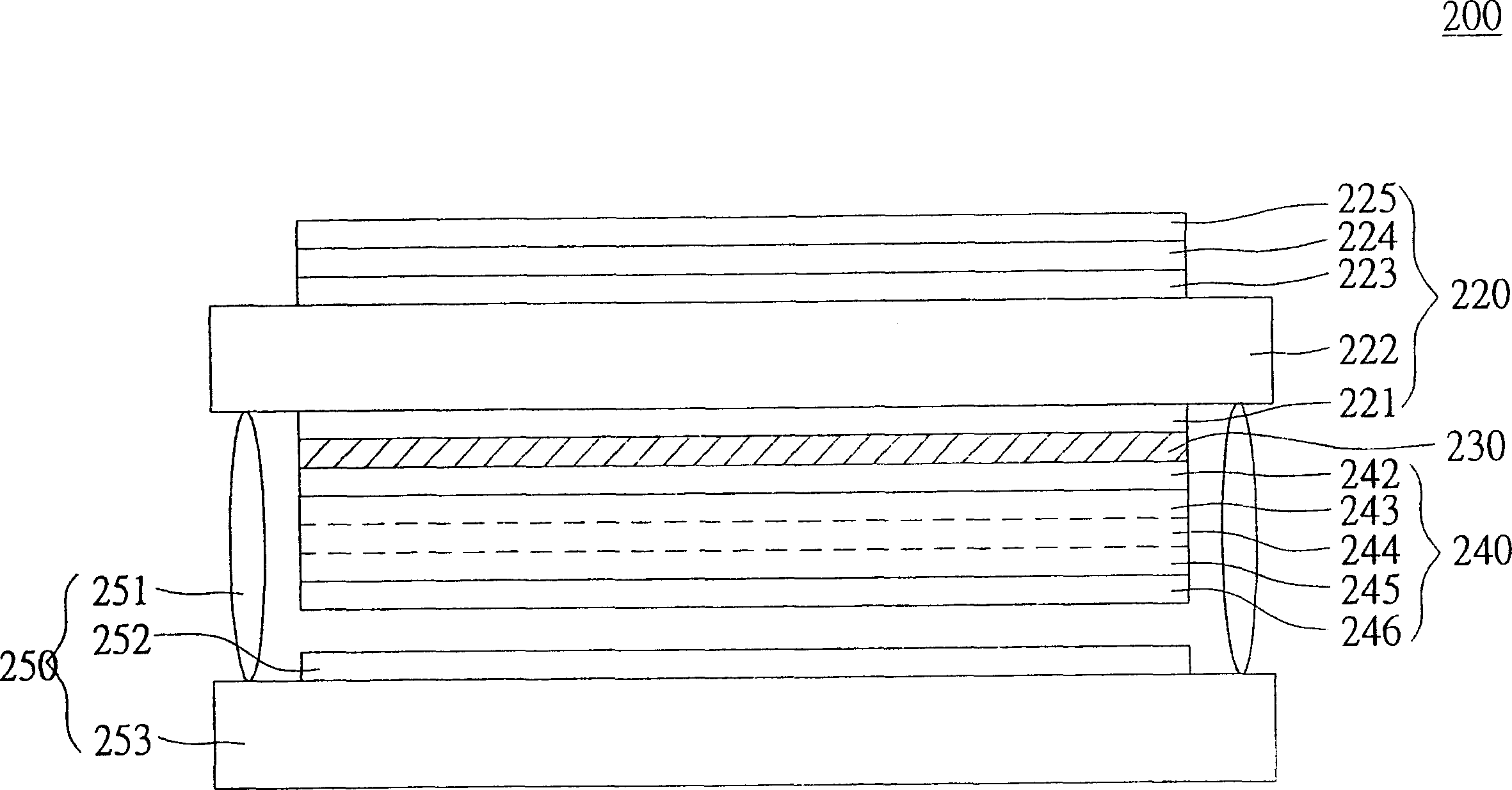

[0029] The main idea of the present invention is to directly form organic electroluminescent display elements on the surface of the capacitive touch panel, and the two are only separated by an insulating layer. The thickness and weight of the flat-panel display can be reduced, and the display quality of the display and the touch performance of the touch panel can be taken into consideration.

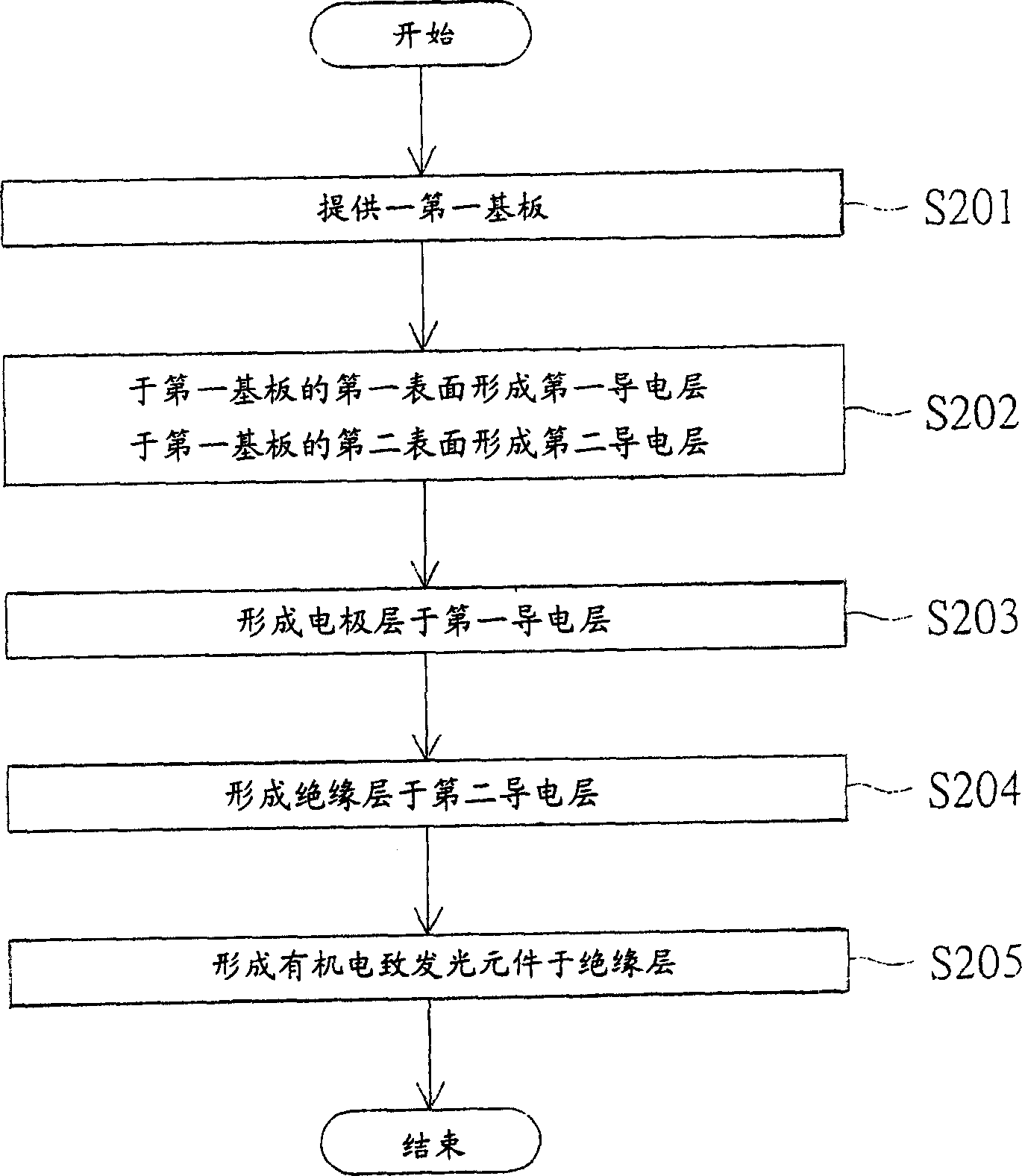

[0030] The plane display of the present invention includes a first substrate, a first conductive layer, a second conductive layer, an electrode layer, an insulating layer and an organic electroluminescence display element. The first conductive layer is formed on the first surface of the first substrate, and the electrode layer is formed on the first conductive layer. The second conductive layer is formed on the second surface of the first substrate, the insulating layer is formed on the surface of the second conductive layer, and the organic electroluminescence display element is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com