Apparatus for condensing a drafted fibre sliver

A sliver and fiber technology, applied in the field of a conveyor belt, can solve problems such as defects in the conveyor belt, damage to the compaction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

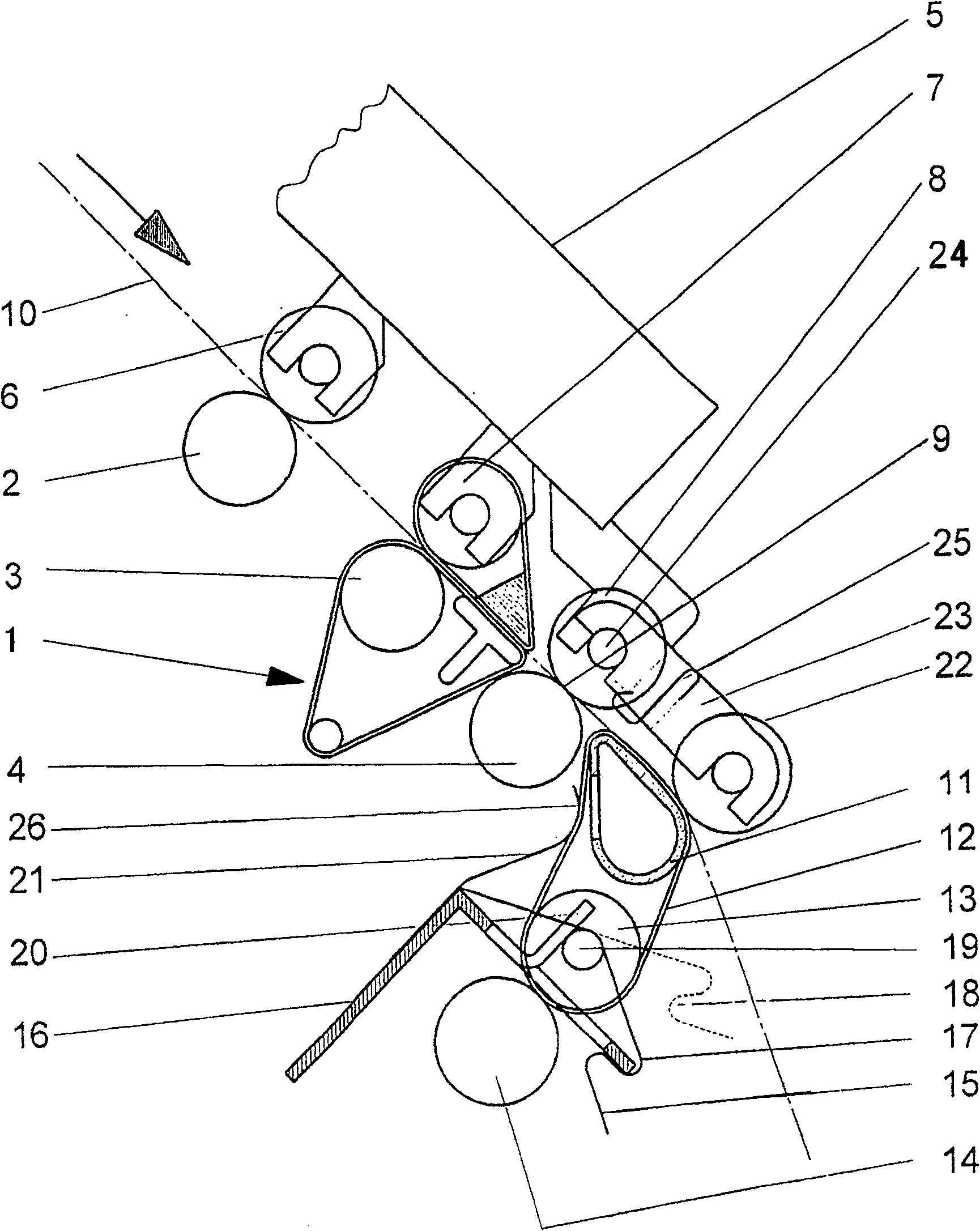

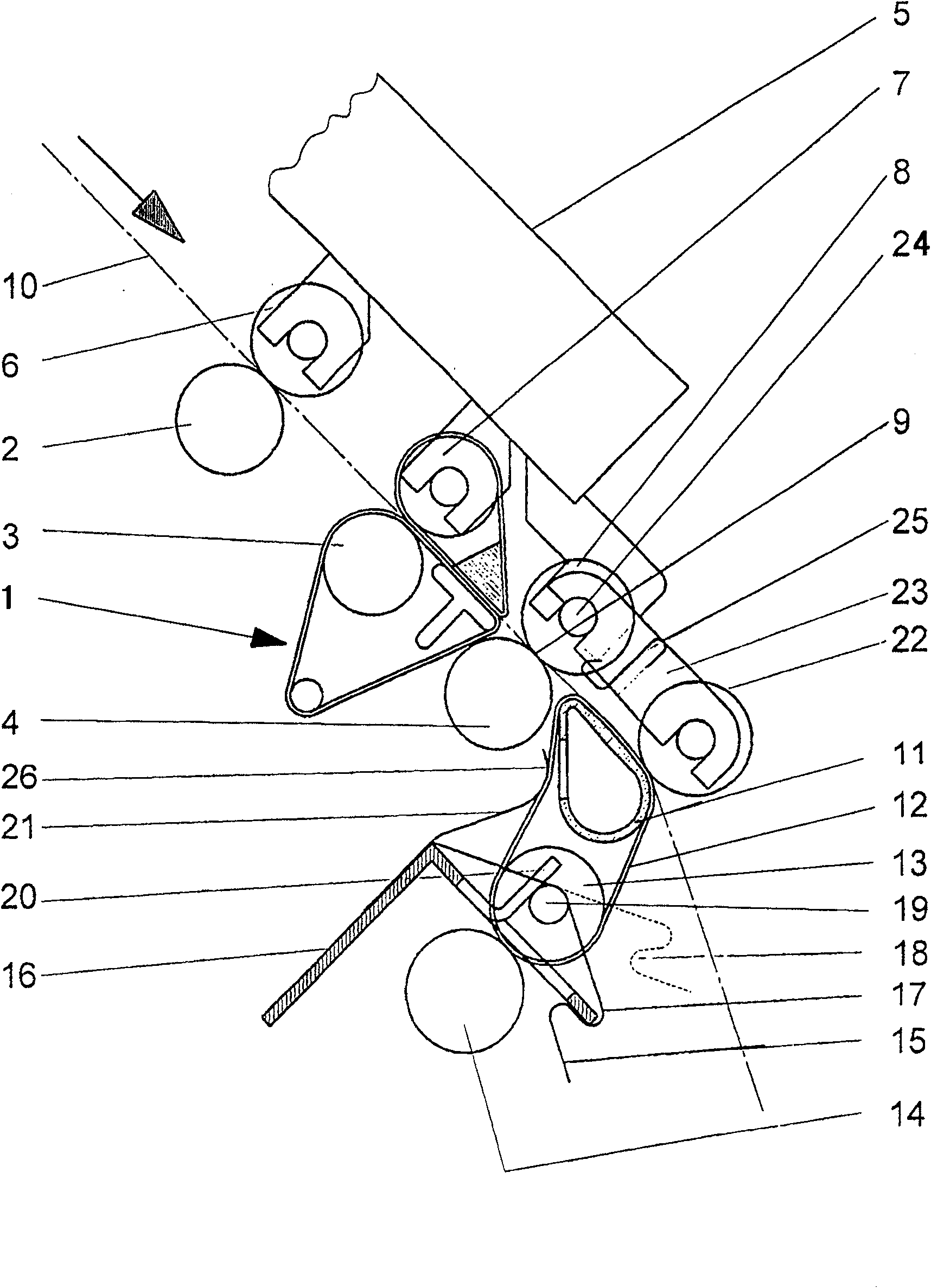

[0024] figure 1 The outlet area of a drafting element 1 is shown, which is used on a ring spinning machine. Three driven lower rollers 2, 3 and 4 are arranged on a shaft (not shown), and three rollers 6, 7 and 8 beside them are contained in a pressure arm 5 and driven. The lower roller 4 and the upper roller 8 jointly form a front roller pair 9 on the drafting element 1 . The drafting of the fed fiber sliver 10 takes place in the drafting unit 1 up to the front roller pair 9, and this is a well-known process.

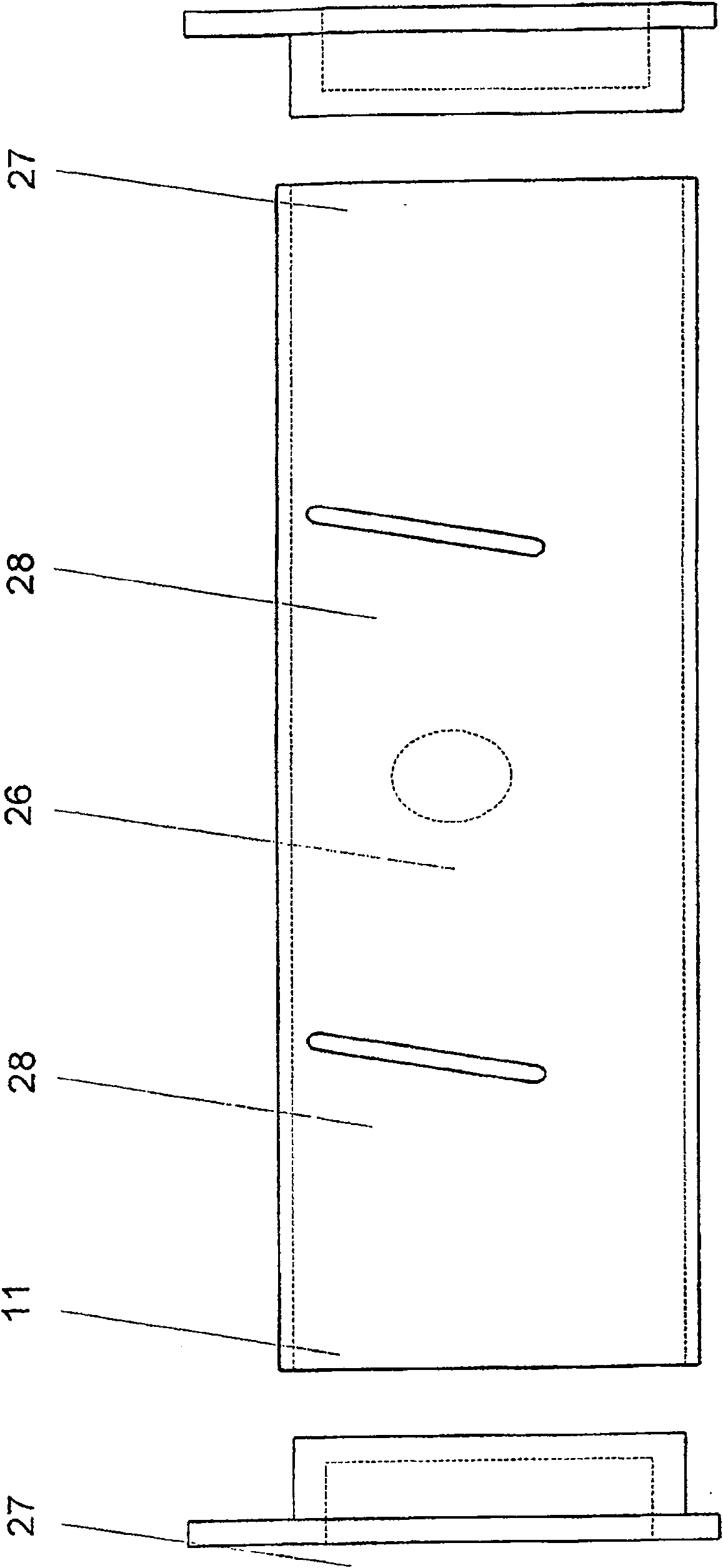

[0025] The compaction zone with the air extraction element 11 , which is connected to the front roller pair 9 , will be described in detail below. Both the suction element 11 and a guide roller 13 are partially surrounded by an air-permeable conveyor belt 12 . At the portion covered by the conveyor belt 12, a guide roller 13 is pressed against a drive roller 14, which is connected to a motor drive unit (not shown). The drive roll 14 and the lower rolls 2, 3 and 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com