Prolon spinning dope for wig and its production method

A technology of spinning stock solution and synthetic fiber, which is applied in the field of spinning stock solution of protein synthetic fiber for wigs, which can solve problems such as allergies, sticking skin, and insufficient raw materials for wig production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

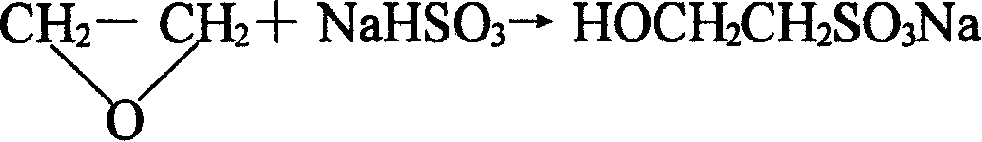

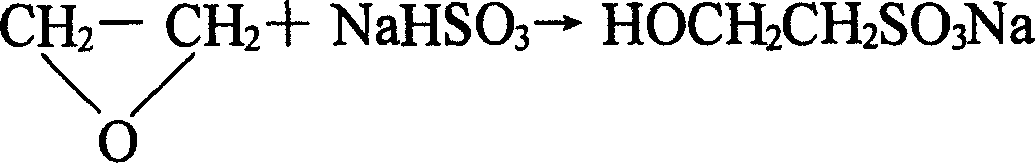

[0012] Embodiment 1. press technology ZL02101961.4; ZL02115722.7; ZL02155315.7 technical requirements in the production of stoste, will be processed and the concentration by weight is 300 kilograms of 10% protein aqueous solution, the concentration by weight is 23 % of polyvinyl alcohol aqueous solution 279 kilograms, the concentration by weight is 6 kilograms of flame retardant 3031 aqueous solution of 50% and 3 kilograms of sodium ethanol sulfonate of dry matter gross weight 3%, respectively at 75 ℃ and stirring State, evenly and slowly add together and copolymerize for 150 minutes, then stand still for 15 hours and then keep stirring for 150 minutes to obtain 588 kg of finished spinning stock solution with a concentration of 17% by weight, and then pass through a special special-shaped spinneret hole. The protein synthetic fiber for wigs can be obtained through the well-known and mature wet spinning production process.

Embodiment 2

[0013] Embodiment 2. according to technology ZL02101961.4; ZL02115722.7; ZL02155315.7 technical requirements in the production of stock solution, will have been processed and the concentration by weight is 267.5 kilograms of protein aqueous solution, the concentration by weight is 23 % of polyvinyl alcohol aqueous solution 204 kilograms, the concentration by weight is 3 kilograms of flame retardant 3031 aqueous solution of 50% and 1.5 kilograms of sodium ethanol sulfonate of dry matter gross weight 1.5%, all at 86 ℃ respectively and in the stirring State, evenly and slowly add together and copolymerize for 120 minutes, then stand still for 12.5 hours and then insulate and stir for 120 minutes to obtain 476 kilograms of finished spinning stock solution with a concentration of 21% by weight, and then obtain a wig as in Example 1. Synthesize fibers from protein.

Embodiment 3

[0014] Embodiment 3. according to technology ZL02101961.4; ZL02115722.7; ZL02155315.7 technical requirements in the production of stock solution, will have been processed and the concentration by weight is 274 kilograms of protein aqueous solution, the concentration by weight is 23 124 kg of polyvinyl alcohol aqueous solution, 1 kg of flame retardant 3031 aqueous solution of 50% by weight and 1 kg of sodium ethanol sulfonate of 1% of the total weight of dry matter, all at 98 ° C and stirring State, evenly and slowly add together and copolymerize for 90 minutes, then stand still for 10 hours and then insulate and stir for 90 minutes to obtain 400 kilograms of finished spinning stock solution with a concentration of 25% by weight, and then obtain the wig as in Example 1. Synthesize fibers from protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com