Process for producing high concentration tert-butyl alcohol by permeation vaporization method and products therefrom

A technology of pervaporation and tert-butanol, which is applied in the field of separation, can solve problems such as high energy consumption, complex production process, and impact on product quality, and achieve the effects of high yield, simple process, and broadened application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

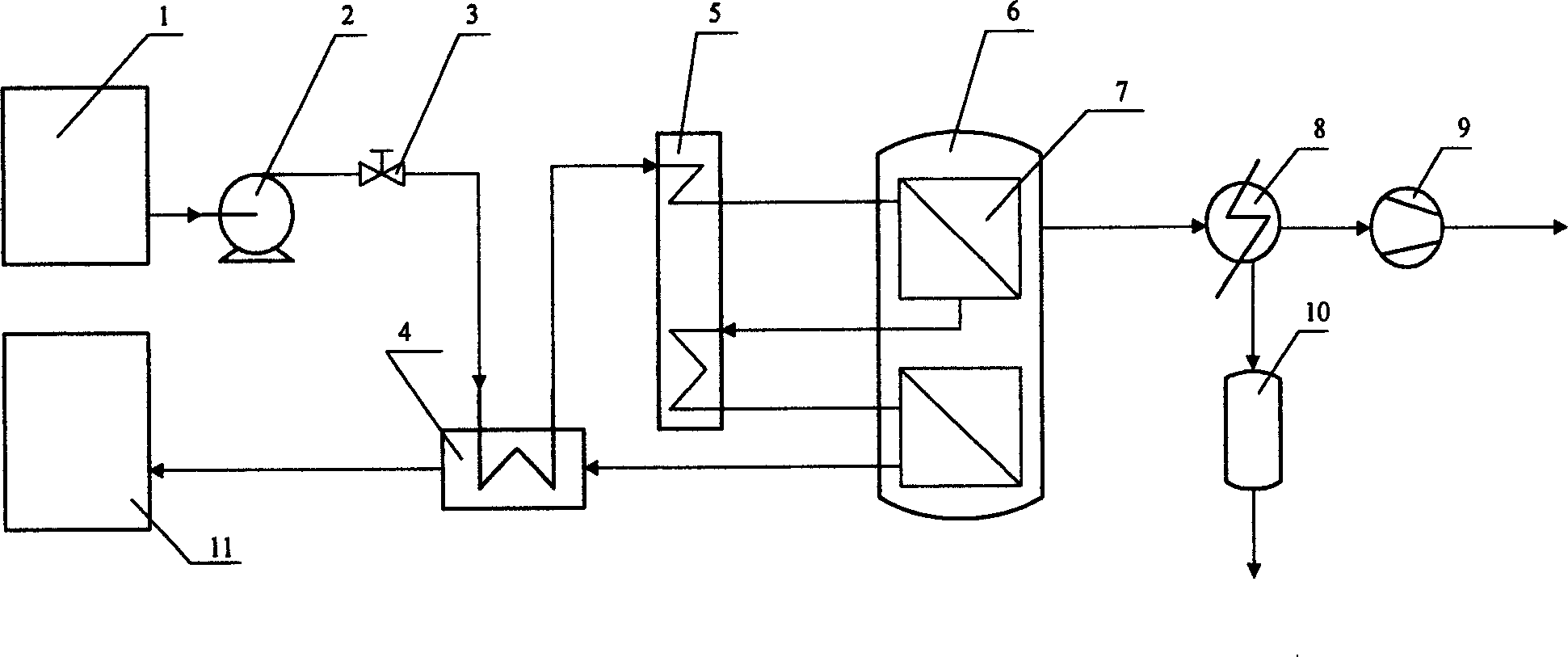

Method used

Image

Examples

Embodiment 1

[0023] Put a dilute aqueous solution with a mass content of 85% tert-butanol in 10m 3 In the raw material tank of the volume, the raw material temperature is normal temperature 25°C. With rated flow rate 0.6m 3 / h, a centrifugal pump with a lift of 65m pumps out the raw material, with a flow rate of 300kg / h, and enters the heat exchanger. The raw material is preheated to 60°C by absorbing the heat of the product material, and then enters a heater, and is heated by 105°C hot water. The raw material is heated to 95°C and enters the vacuum cover, and the inlet pressure of the membrane separator is 0.3MPa. In the vacuum cover, the water-permeable membrane divides the membrane separator into two chambers, the upstream side and the downstream side. The upstream side is a liquid phase chamber, and the downstream side is a vapor phase chamber. 30mmHg absolute pressure. In the liquid phase chamber of the pervaporation membrane separator in the vacuum cover, the liquid phase material...

Embodiment 2

[0025] Put a dilute aqueous solution with a mass content of 99% tert-butanol in 10m 3 In the raw material tank of the volume, the raw material temperature is normal temperature 25°C. With rated flow rate 0.6m 3 / h, a centrifugal pump with a head of 65m pumps out the raw material with a flow rate of 300kg / h, and enters the heat exchanger, preheats the raw material to 60°C by absorbing the heat of the product material, and then enters the electric heater to heat the raw material to 95 ℃, enter the vacuum cover, and the inlet pressure of the membrane separator is 0.3MPa. In the vacuum cover, the water-permeable membrane divides the membrane separator into two chambers, the upstream side and the downstream side. The upstream side is a liquid phase chamber, and the downstream side is a vapor phase chamber. 10mmHg absolute pressure. In the liquid phase chamber of the pervaporation membrane separator in the vacuum cover, the liquid phase material flows through the upstream side of...

Embodiment 3

[0027] Put a dilute aqueous solution with a mass content of 85% tert-butanol in 10m 3 In the raw material tank of the volume, the raw material temperature is normal temperature 25°C. With rated flow rate 0.6m 3 / h, a centrifugal pump with a lift of 65m pumps out the raw material with a flow rate of 300kg / h, and enters the heat exchanger. The raw material is preheated to 60°C by absorbing the heat of the product material, and then enters the steam heat exchanger to heat the raw material to 95°C, enter the vacuum cover, and the inlet pressure of the membrane separator is 0.4MPa. In the vacuum cover, the water-permeable membrane divides the membrane separator into two chambers, the upstream side and the downstream side. The upstream side is a liquid phase chamber, and the downstream side is a vapor phase chamber. 10mmHg absolute pressure. In the liquid phase chamber of the pervaporation membrane separator in the vacuum cover, the liquid phase material flows through the upstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com