Optical alignment quick positioning tacking device

An optical collimation and fast technology, applied in the parts, instruments, casings and other directions of the instrument, can solve the problem that the multi-band comprehensive photoelectric performance detection device cannot be used, and the adjustment or positioning of multiple optical devices or instruments cannot be realized. problems, to improve work performance and combat effectiveness, and to achieve the effect of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

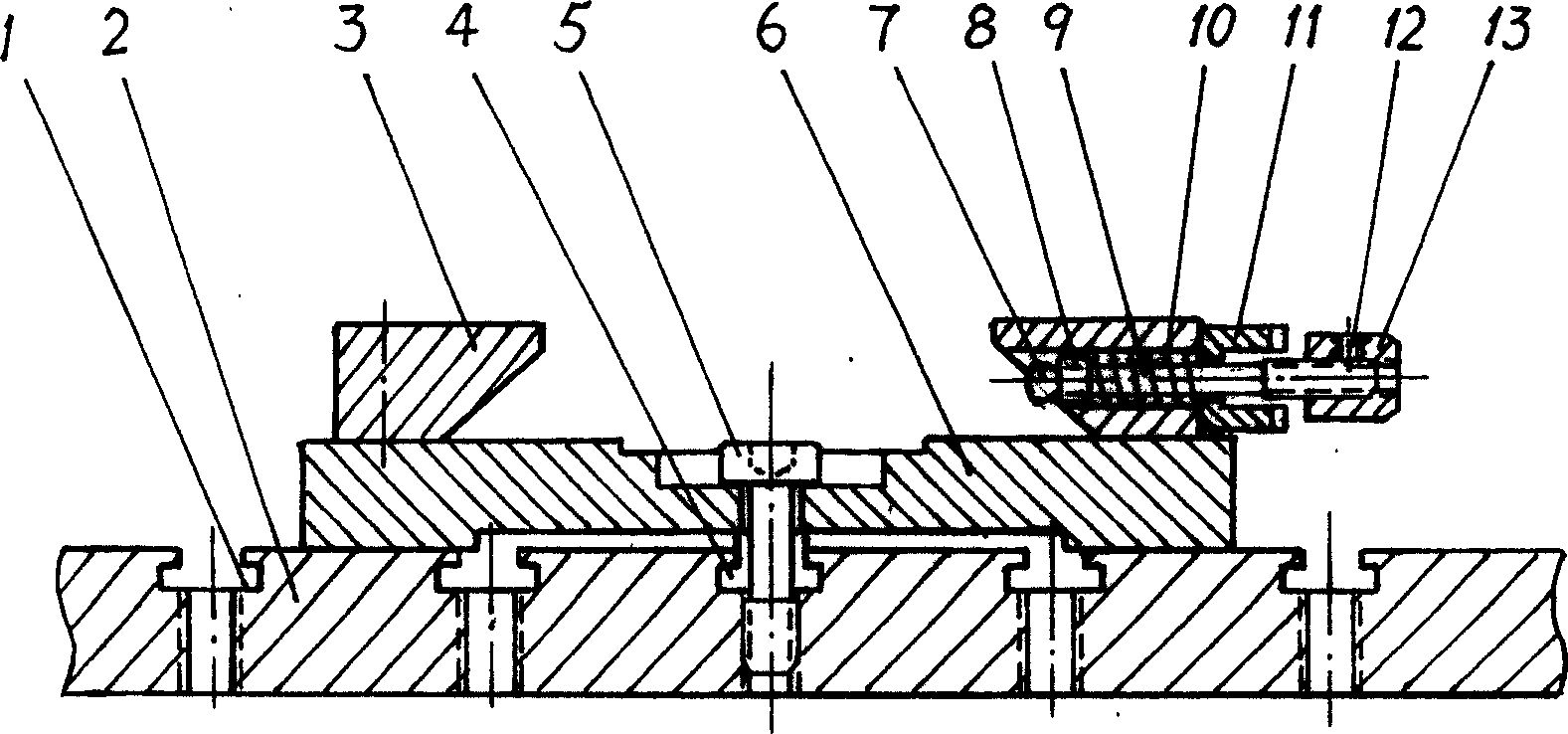

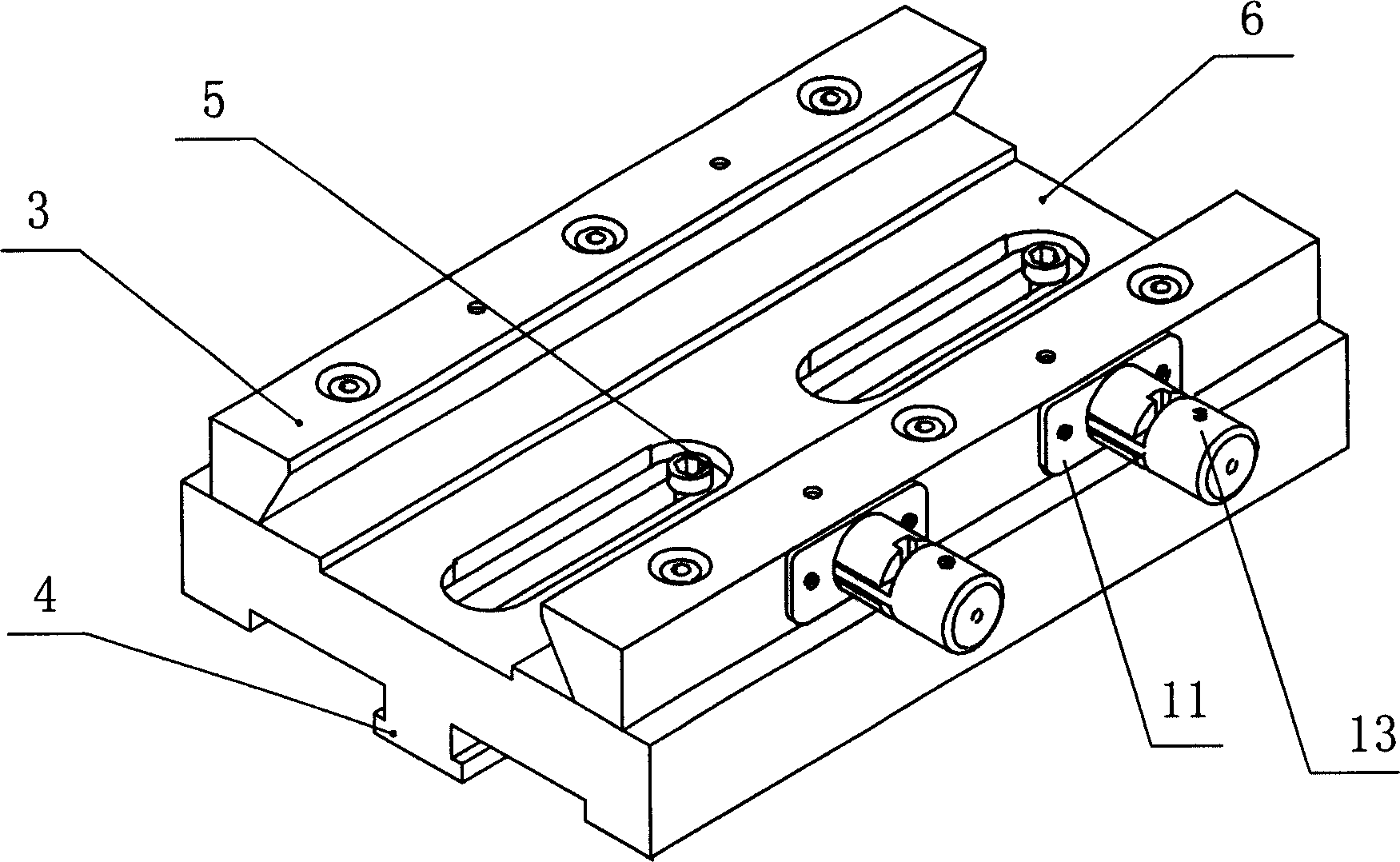

[0015] like figure 1 , Figure 4 Shown, on the planar workbench frame 2, be provided with equidistant some inverted T-shaped slots 1 perpendicular to each other vertically and horizontally, and screw holes are provided on the plate surface at the junction of the vertical and horizontal slots. Screw holes are preferably opened at each junction, so that the movable base can be fixed at any position on the workbench frame.

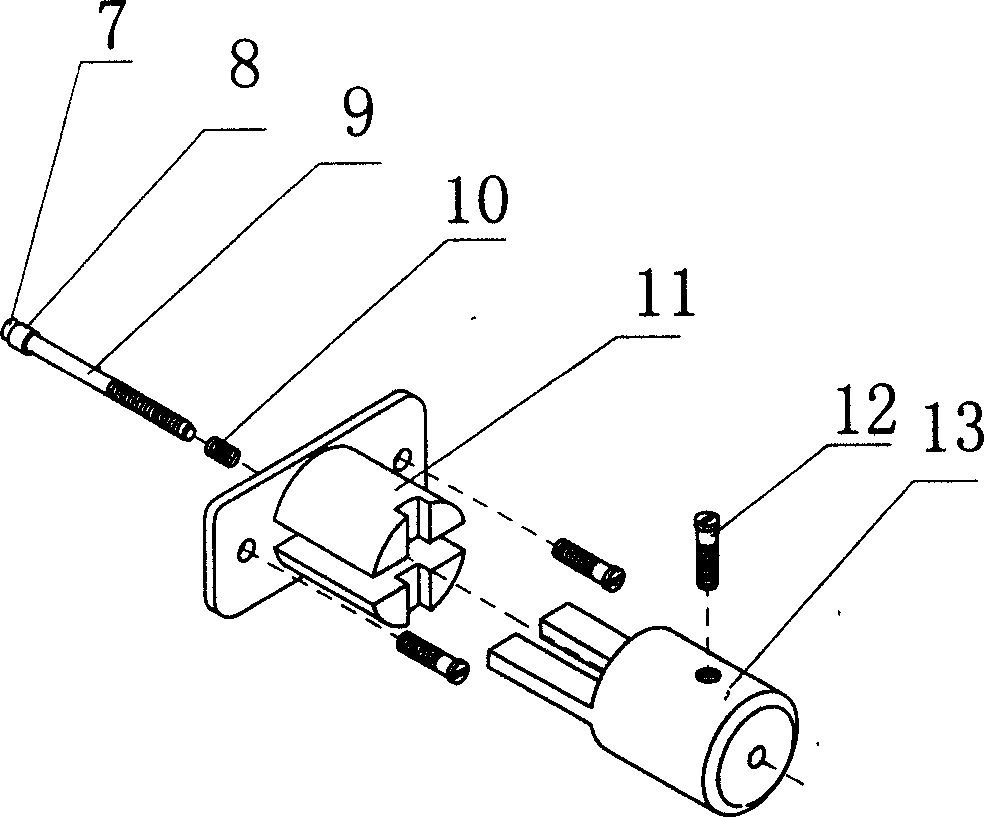

[0016] like figure 1 , image 3 As shown, the movable base 6 is a rectangular plate body, and a lower guide rail 4 with an inverted T-shaped cross section is formed on the center line of symmetry of its bottom surface. The bar slot is opened on the center line of symmetry of the movable base 6, and its width should be less than the nut diameter of the fastening screw 5. In order to ensure the smooth flow of the top surface of the movable base, a stepped groove is provided on the top of the bar-shaped slot hole, so that the top surface of the nut is submer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com