Bolt assemble sequence control equipment

A sequence control and bolt technology, applied in the direction of electrical program control, program control in sequence/logic controller, screwdriver, etc., can solve the problems of not being suitable for mass production, unable to realize process quality control, errors and leakage, etc., to avoid Assembly quality problems, good cost performance, easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

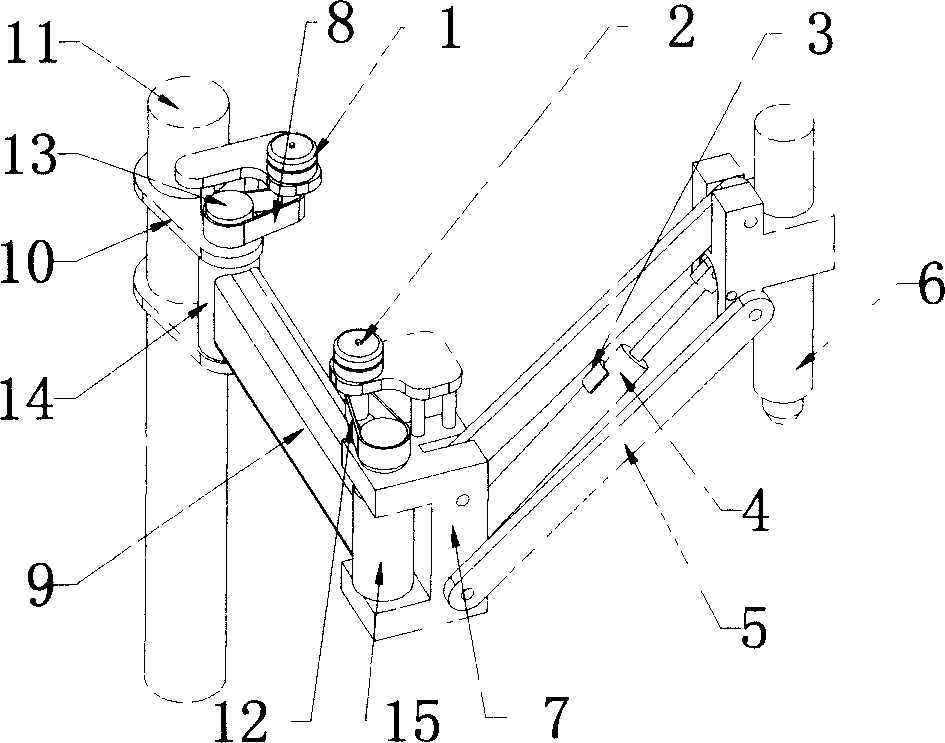

[0013] Such as Figure 1 Shown, the present invention includes: angular displacement sensor 1, angular displacement sensor 2, linear displacement sensor 3, piston cylinder 4, strut 5, bolt tightening tool 6, hinged head 7, rotary arm 9, rotary joint 10, rotary bracket 11. Among them, the rotary mechanism composed of the rotary bracket 11, the rotary joint 10, the rotary arm 9 and the angular displacement sensor 1, the hinged rotary mechanism composed of the hinged joint 7 and the angular displacement sensor 2, the strut 5, the piston cylinder 4, the linear displacement sensor 3, the bolt The vertical up and down movement mechanical mechanism that tightening tool 6 forms.

[0014] In the slewing mechanism, the slewing arm 9 is connected to the slewing joint 10 on the equipment support through a pin shaft 14, and the angular displacement sensor 1 is on the slewing joint 10 to form a first-stage slewing mechanism in the horizontal direction. The pin connected to the slewing arm 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com