Seal for use between two mobile parts of a hydraulic machine

A technology of relative motion and moving parts, applied in the field of gap devices, can solve the problems of pump power exhaustion, power increase, processing technology troubles, etc., and achieve the effect of simple bearing clearance and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

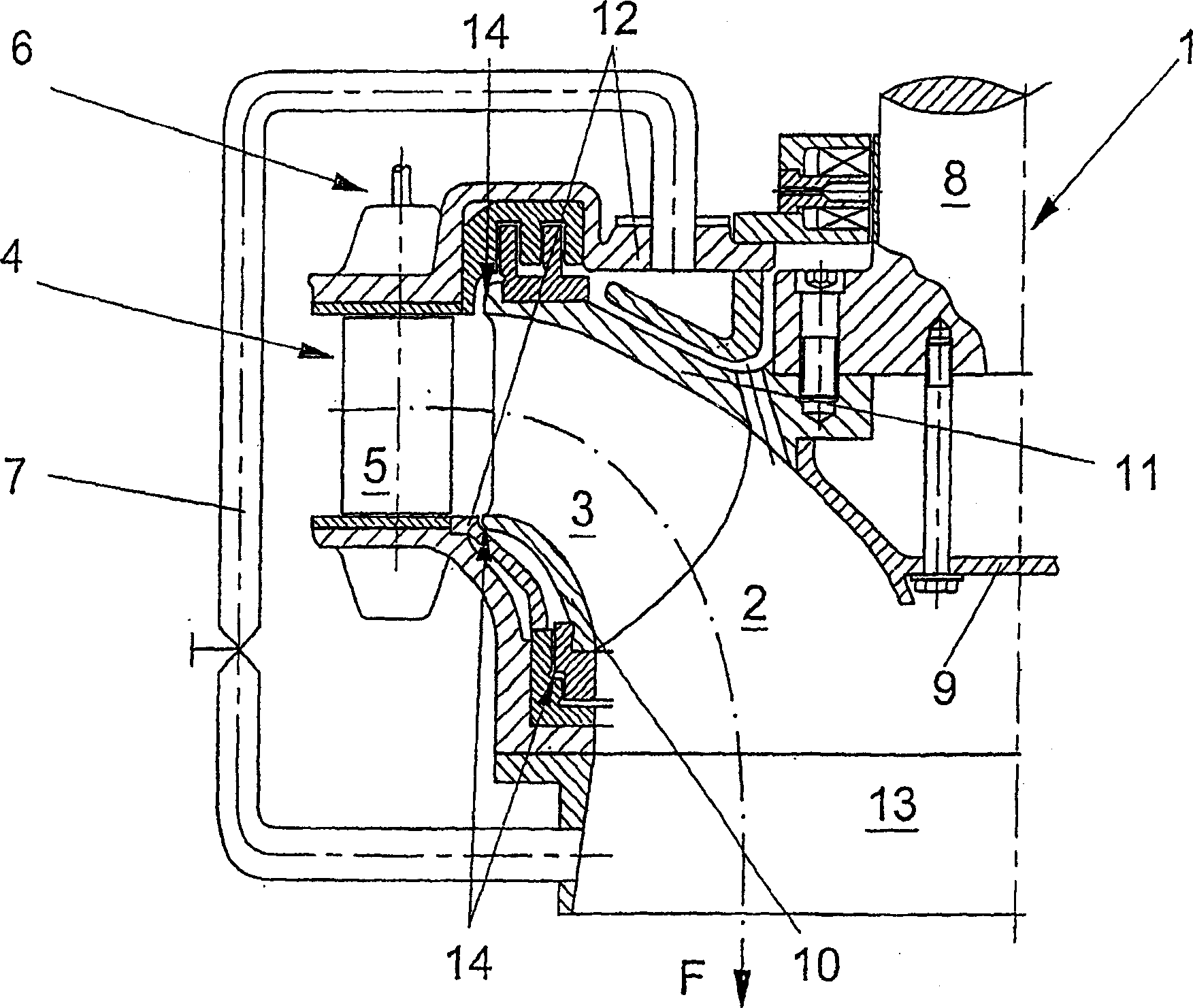

Method used

Image

Examples

Embodiment Construction

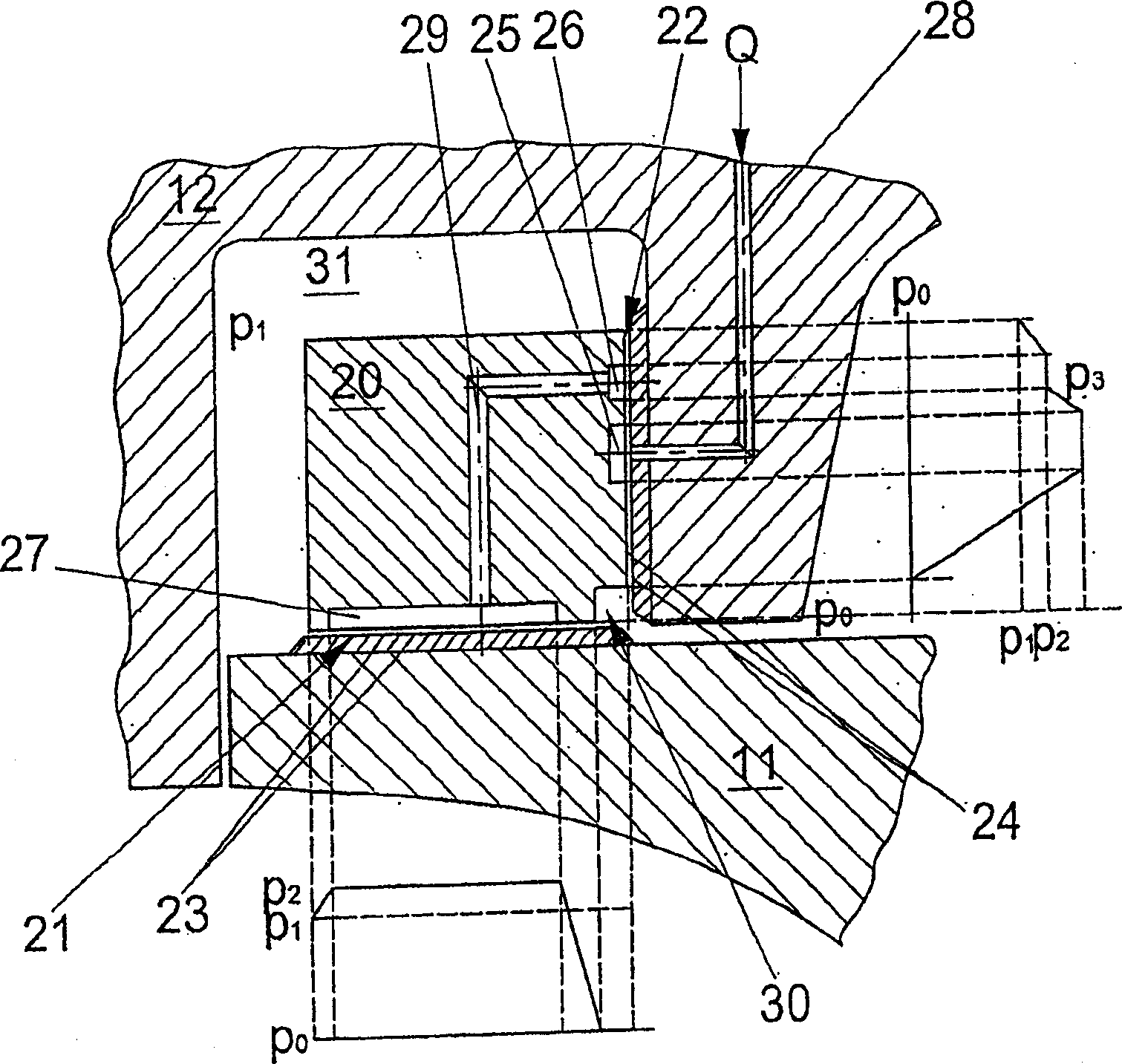

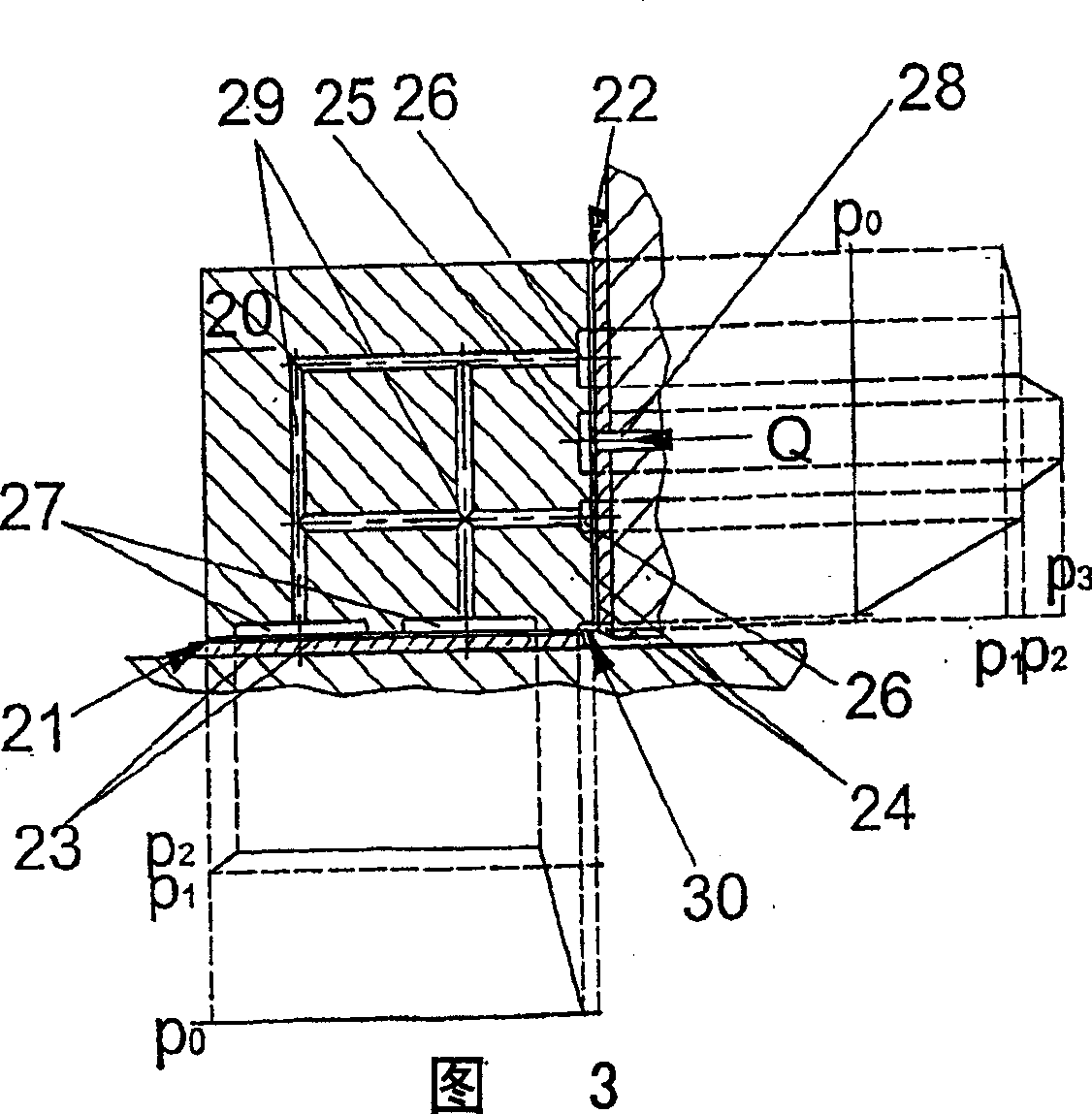

[0038] Before actually describing, some terms are defined and elaborated below.

[0039] Generally, the terms "support" are used such as groove and bearing surface, which in this application denote ring-shaped or cylindrical structures, respectively. In this case, the support member or bearing surface can have any width and depth or height and can be continuous in the circumferential direction or partially interrupted at one or several points. Of course, the support member may have any cross-sectional shape, for example triangular grooved, and need not be grooved.

[0040] Hydrostatic bearings always consist of mutually opposing bearing surfaces, wherein at least one bearing element, such as a groove, groove, etc., is provided on at least one bearing surface. If a number of bearings are arranged on the circumference, since one bearing is partially broken as described above, a plurality of hydrostatic bearings arranged on the circumference must also be mentioned. For the sake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com