Intelligent network bottle blowing machine

An intelligent network and blow molding machine technology, applied in the field of blow molding machines, can solve the problems that the blow molding machines cannot monitor and display relevant information in real time, and achieve the effects of low cost, easy maintenance, and convenient elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

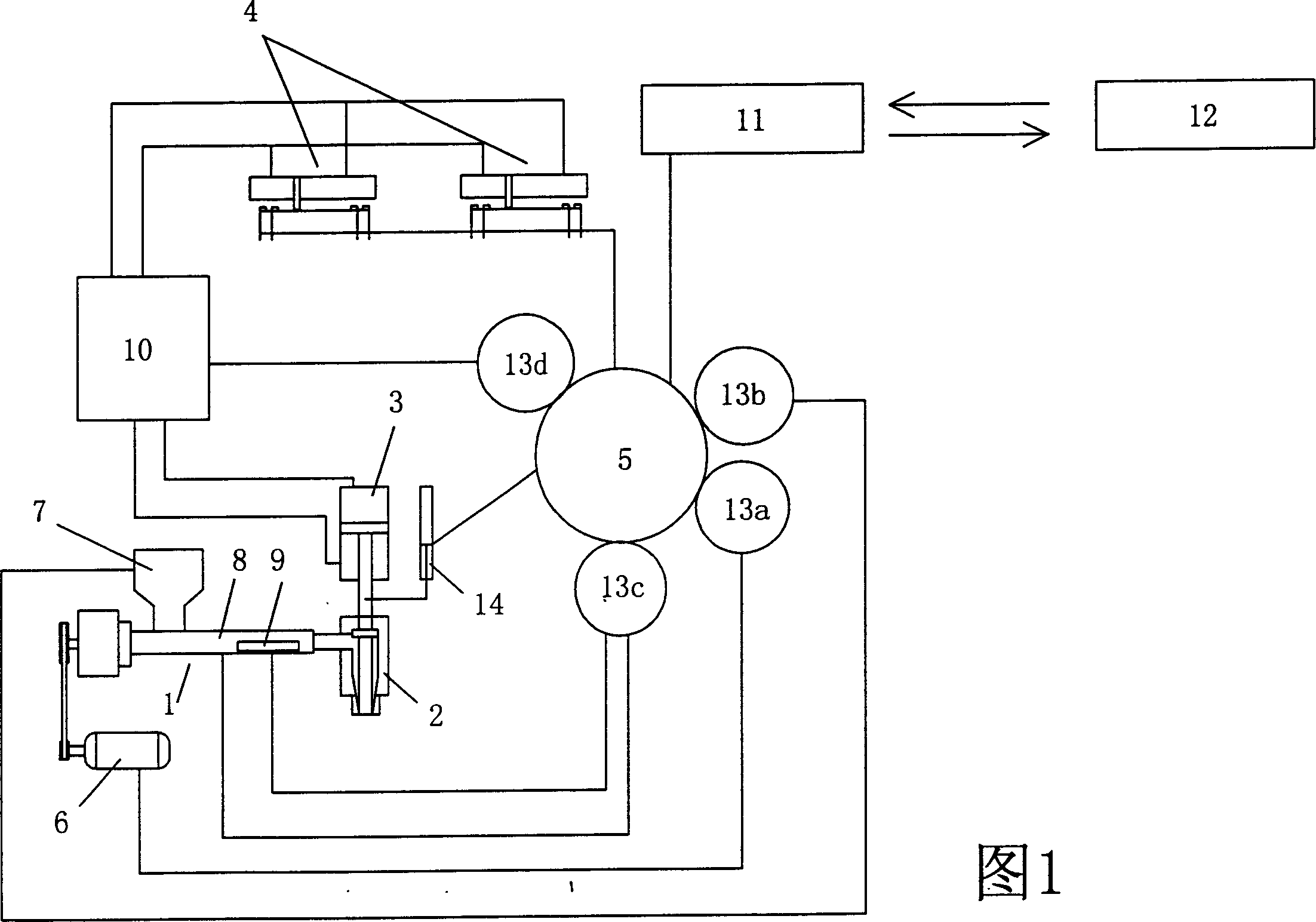

[0014] As shown in Figure 1, an intelligent network blow molding machine is composed of an extruder 1, a die head 2, an injection cylinder 3, a mould, a mobile cylinder 4 and a control computer 5. The extruder 1 is driven by a motor 6, The extruder 1 is provided with a hopper 7 and a barrel 8, the barrel 8 is equipped with a heating coil 9, the barrel 8 is equipped with a die head 2, the upper end of the die head 2 is equipped with an injection cylinder 3, and the lower end of the die head 2 is equipped with a The mould, the mold is opened and closed by the mobile cylinder 4, the injection cylinder 3 and the mobile cylinder 4 are controlled by the hydraulic workstation 10, the motor 6, the hopper 7, the barrel 8, the injection cylinder 3 and the mobile cylinder 4 are equipped with data reading device, the read data is transmitted to the control computer 5, and the control computer 5 performs analysis and calculation and instructs each component to operate according to the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com