Magnetic tape cartridge and recorder/reproducer a magnetic tape cartridge

一种盒式磁带、再现装置的技术,应用在在磁带上信息的记录、磁记录、磁记录头等方向,能够解决电阻低、自旋阀元件易破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

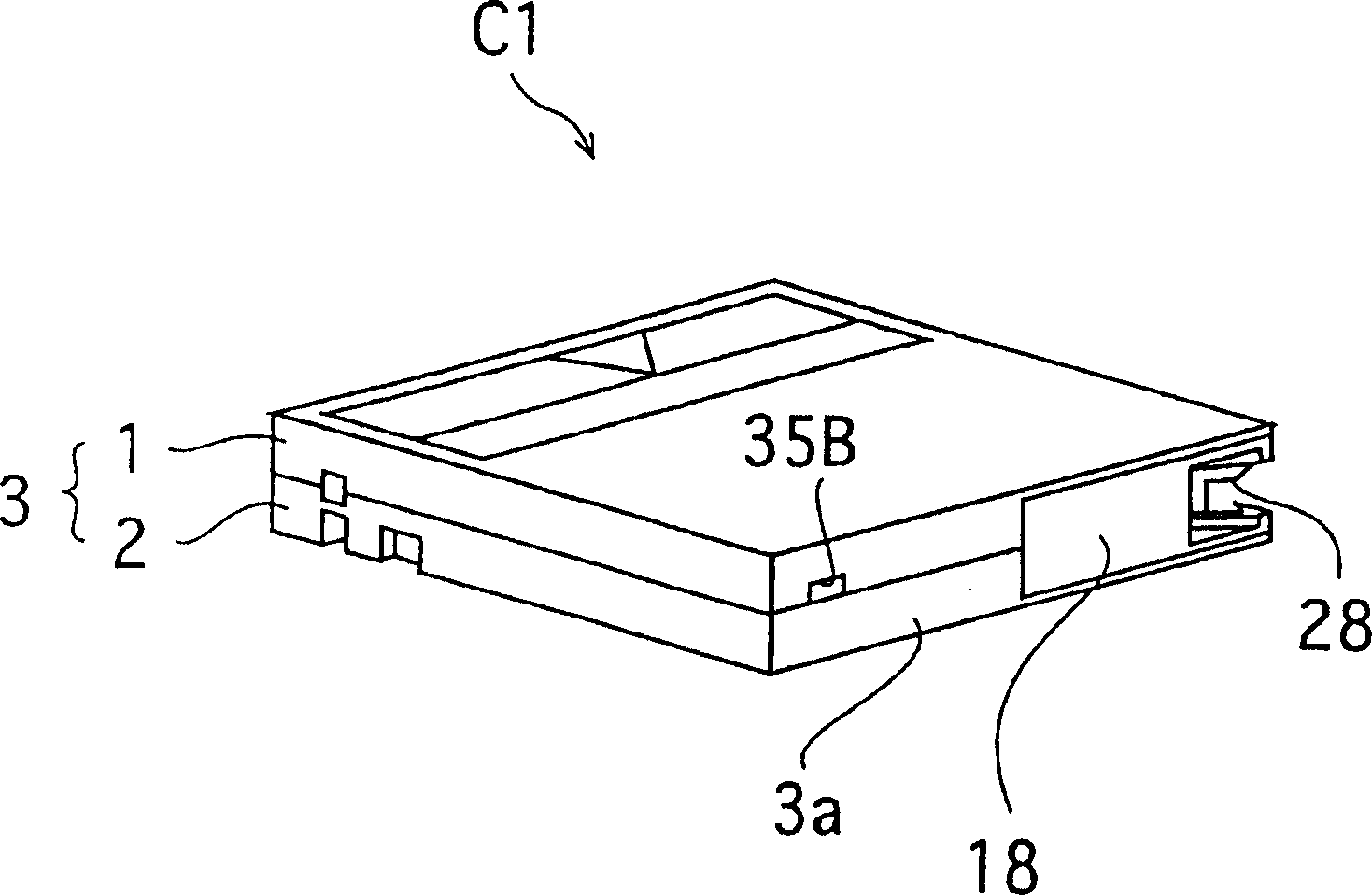

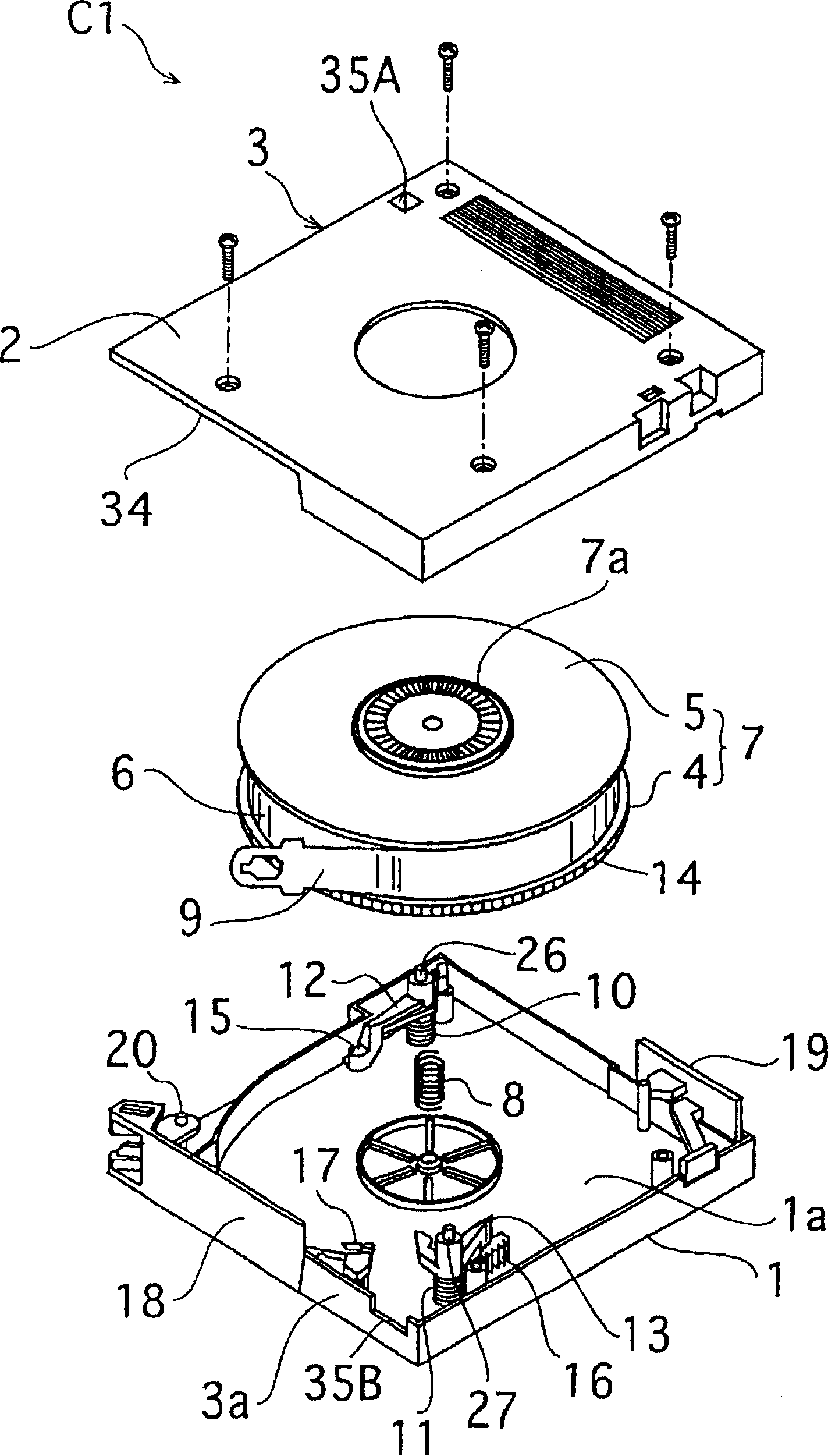

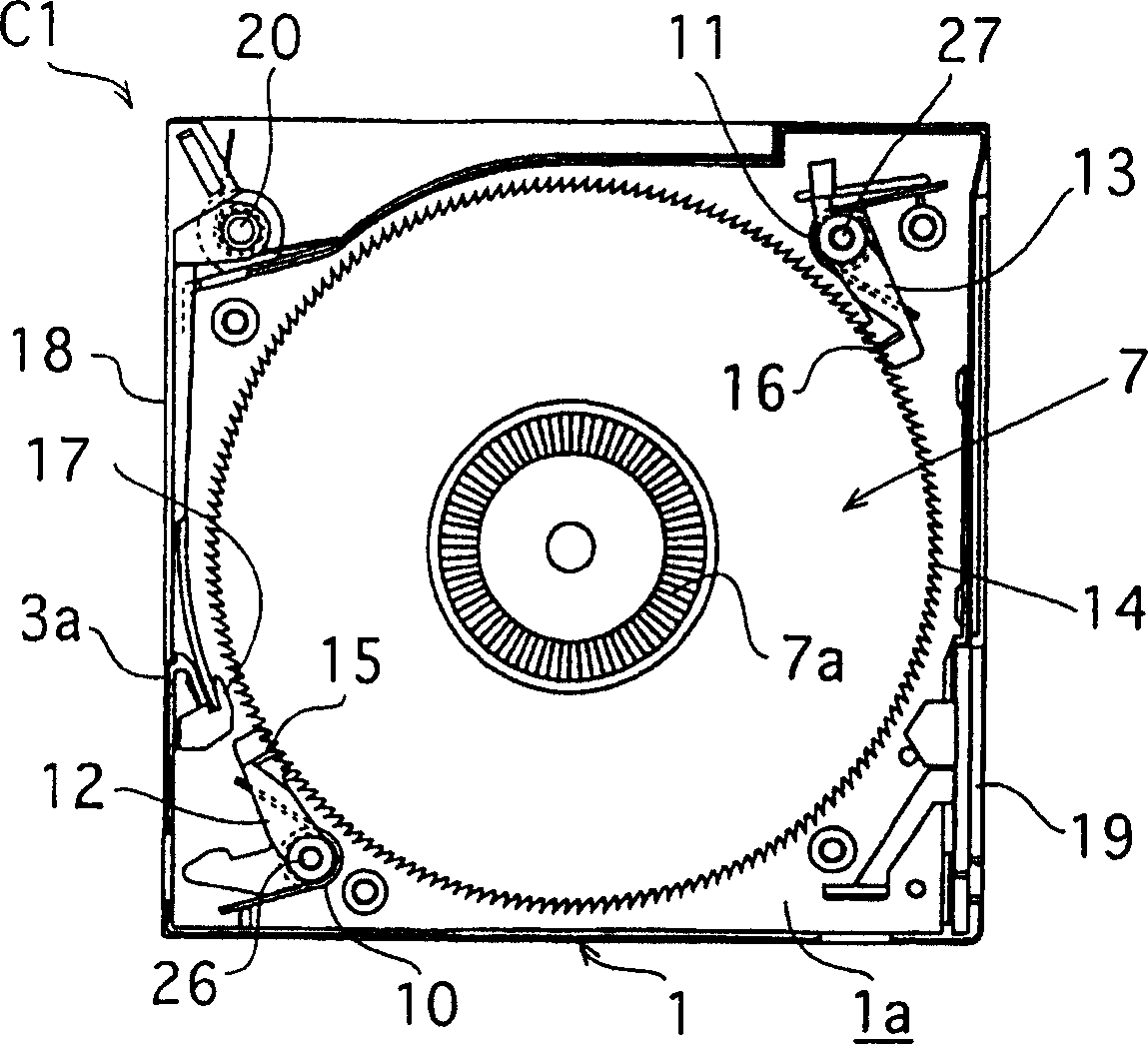

no. 1 example

[0050] In the present embodiment, the upper flange 4 (including the reel hub 7A) and the lower flange 5 constituting the tape reel 7 are formed of a conductive material such as metal or conductive plastic, and the magnetic tape 6 of the above structure is electrically connected to the tape reel 7.

[0051] There is no particular limitation with respect to the metallic material forming the tape reel 7, but a metallic material such as aluminum, magnesium or titanium metal material having a small specific gravity is preferably used for the main material of the tape reel. Conductive plastic refers to a synthetic resin material, such as POM or ABS, that contains conductive fillers to provide electrical conductivity.

[0052] Here, the conductive filler refers to a filler added for imparting conductivity to a material, and examples thereof include particulate fillers, flake fillers, and fibrous fillers. Representative examples of particulate fillers are conductive carbon, and repre...

no. 2 example

[0062] Figure 7 to Figure 9 A second embodiment of the present invention is shown. In the drawings of the second embodiment, the same elements or parts as those in the drawings of the first embodiment are designated by the same reference numerals, and detailed descriptions thereof are omitted.

[0063] The magnetic tape cassette C2 according to the present embodiment has a structure in which the upper half 51 and the lower half (not shown) are made of a synthetic resin material having low discharge characteristics, for example, one that imparts electrical conductivity to the cassette body 53 Sexually conductive plastic.

[0064] In the cassette body 53, there is provided an arm member 40 for electrically connecting the magnetic surface 6M of the magnetic tape 6 having the above-described structure to the inner wall of the cassette body 53. The arm member 40 is composed of a metallic material, such as aluminum alloy or stainless steel, or conductive plastic, and the base por...

no. 3 example

[0073] Figure 10 A cassette C3 according to a third embodiment of the present invention is shown. In the drawings of the third embodiment and the drawings of the second embodiment described above, the same elements or parts are designated by the same reference numerals, and detailed descriptions thereof are omitted.

[0074] In this embodiment, the rear surface 6B of the magnetic tape 6 is electrically grounded using the conductive arm member 43 . The arm edge 43a of the arm member 43 is in elastic contact with the rear surface 6B of the magnetic tape 6 which is wound on the tape reel 7 under a predetermined elastic force F in the diametrical direction. The arm member 43 is formed with a length such that the arm edge 43a can come into contact with the reel hub 7A of the tape reel 7, so that the arm edge 43a is constantly in elastic contact with the rear surface 6B of the magnetic tape 6 in accordance with the decrease in the winding diameter of the magnetic tape 6 .

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com