Continuous ion exchage extracting process for L-phenylalanine

A continuous ion and phenylalanine technology is applied in the field of continuous ion exchange extraction process of L-phenylalanine, which can solve the problems of low extraction yield and product purity, low utilization rate of upper column resin and high product extraction cost. , to achieve the effect of reducing extraction cost, realizing clean process production and saving acid and alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

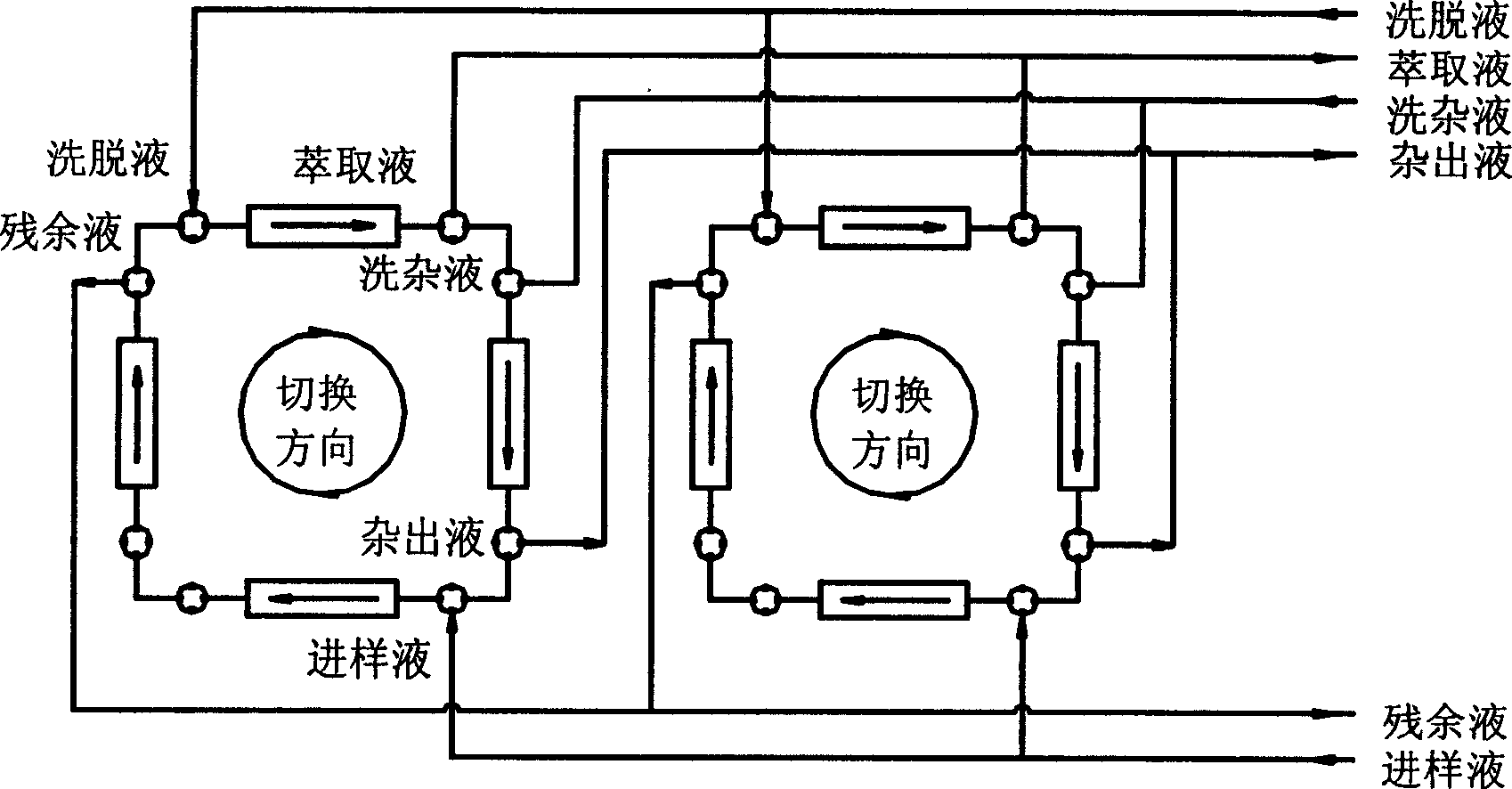

Image

Examples

Embodiment 1

[0031] Take 10m 3 The upper column liquid, the concentration of L-phenylalanine is 20 g / L, with 2m 3 / h feed rate into the continuous chromatographic system, the adsorption pH is controlled at 2.0, and then 0.3mol / l eluent at 2m 3 The flow rate of / h washes off the phenylalanine adsorbed on the resin, and then obtains 197.6 kilograms of L-phenylalanine crystals after concentrating, crystallizing and drying the obtained L-phenylalanine eluent, and the purity is 98.8%, the yield is 98.5%.

Embodiment 2

[0033] Take 10m 3 The upper column liquid, the concentration of L-phenylalanine is 20 g / L, with 3m 3 / h feed rate into the continuous chromatographic system, the adsorption pH is controlled at 2.0, and then 0.3mol / l eluent at 2m 3 The flow rate of / h washes off the phenylalanine adsorbed on the resin, and then obtains 196.2 kilograms of L-phenylalanine crystals after concentrating, crystallizing and drying the obtained L-phenylalanine eluent, and the purity is 99.7%, the yield is 97.8%.

Embodiment 3

[0035] Take 10m 3 The upper column liquid, the concentration of L-phenylalanine is 20 g / L, with 4m 3 / h feed rate into the continuous chromatographic system, the adsorption pH is controlled at 2.0, and then 0.5mol / l eluent at 1m 3 The flow rate of / h washes off the phenylalanine adsorbed on the resin, and then obtains 195.6 kilograms of L-phenylalanine crystals after concentrating, crystallizing and drying the obtained L-phenylalanine eluent, and the purity is 98.4%, the yield is 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com