Plant growth media and processes for production thereof and compositions for use therein

A technology for plant growth and culture medium, applied in the field of premixed compositions, can solve the problems of inability to re-wet effectively, decrease in effectiveness, decrease in effectiveness of surfactants, and the like, and achieve the effect of decreasing effectiveness of continuous wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] By mixing 601.40 grams of desiccated coir pith (20% or less moisture content w / w) with 400 grams of a nonionic surfactant (sold under the trade name Pluronic L62 by BASF Corporation containing polyoxyethylene and polyoxypropylene) A block copolymer alkoxylated polyol nonionic surfactant) and 3600 grams of water were mixed to prepare a premix composition. The mixture was then air-dried in a glasshouse to improve flowability and the resulting intermix composition was weighed to determine a total weight of the premix composition of 983 grams. Thus, the surfactant content of the premix composition was calculated to be 40.7% (400 grams of surfactant in the composition / 983 grams of the total weight of the premix composition).

[0038] Then, 0.70 grams of the intervention mix composition containing 40.7% surfactant was incorporated into 1 liter of plant growth medium containing 70% (volume) sphagnum peat and 30% (volume) coir pith. This amount of premixed composition will del...

Embodiment 2

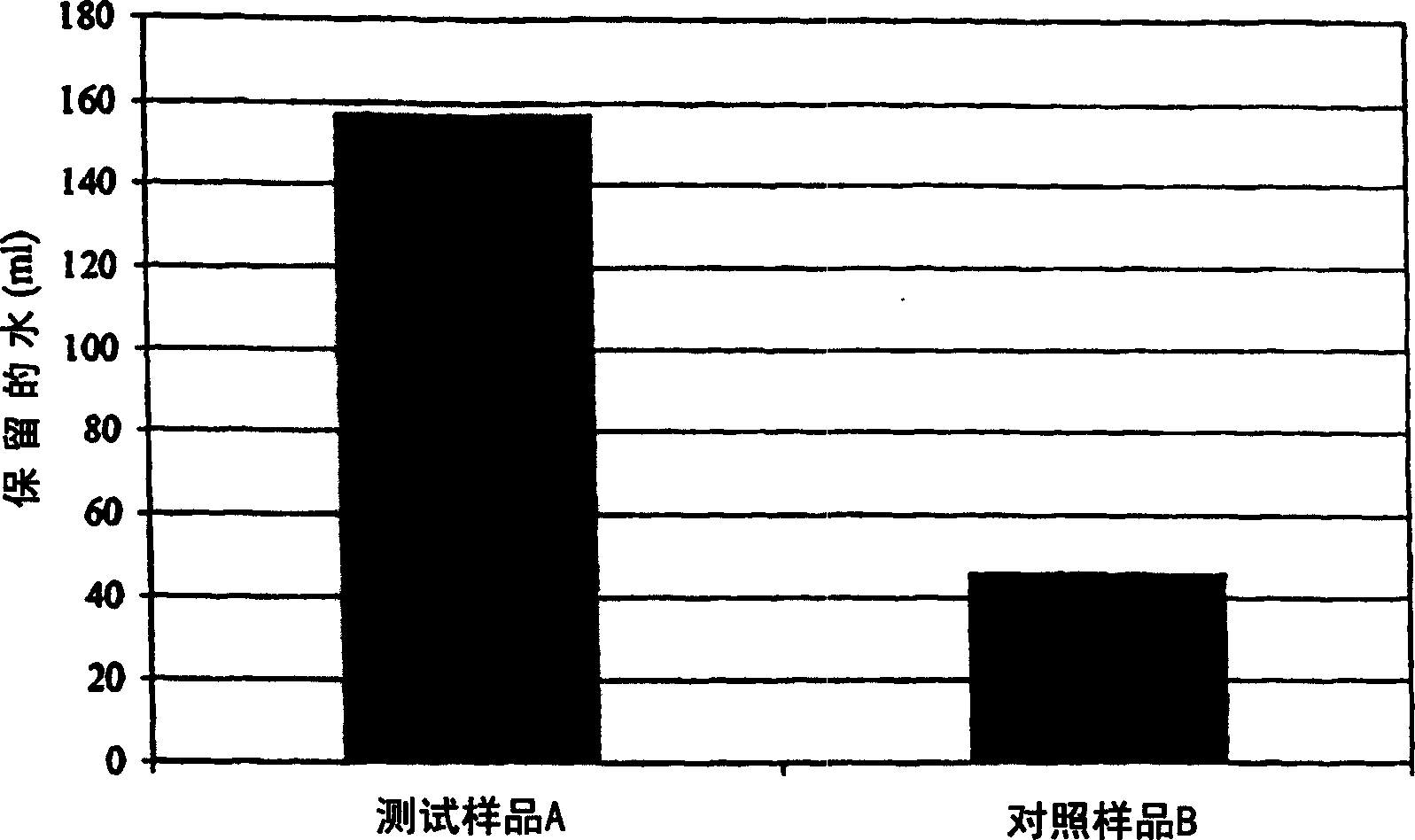

[0041] This example serves to demonstrate that premix compositions of the present invention containing coir pith and surfactants provide enhanced rewetting characteristics in plant growth media, such as potting soil, that surfactants alone do not.

[0042] A premix composition was prepared by mixing 70 grams of copra pith with 70 grams of a nonionic surfactant (proprietary nonionic surfactant sold under the tradename ACA 2000M by Aquatrols, USA). Thus, the surfactant content of the premix composition was calculated to be 50% (70 grams of surfactant in the composition / 140 grams of the total weight of the premix composition).

[0043] Prepare potting soil consisting of 45% sphagnum peat, 45% composted bark powder, 10% perlite mix and divide into 3 batches. Apply the following treatments to the potting soil:

[0044] 1. Spray 4 fluid ounces per cubic yard of ACA 2000M Surfactant to the first batch of potting soil;

[0045] 2. Apply 4 fluid ounces per cubic yard of ACA 2000M Sur...

Embodiment 3

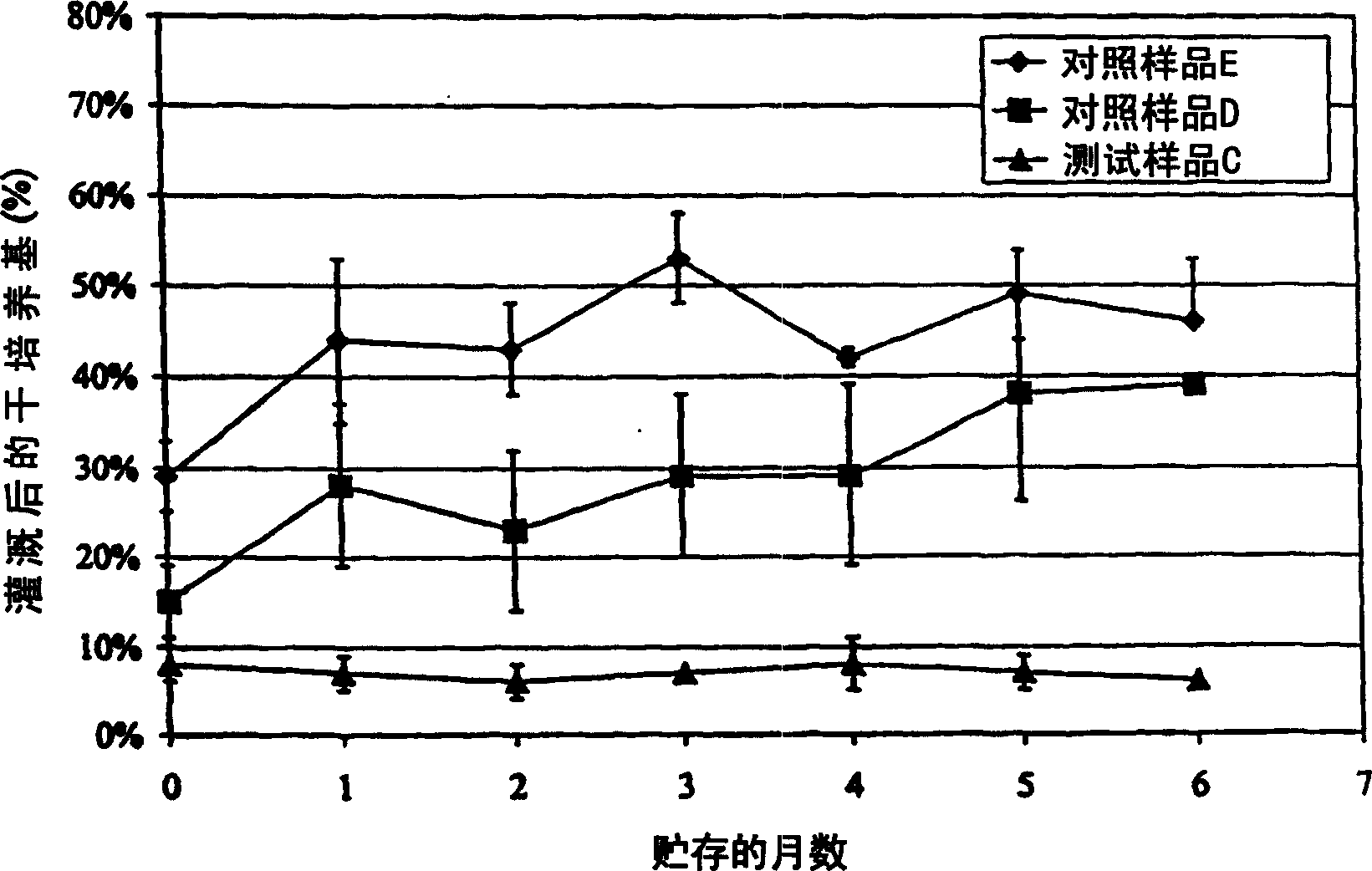

[0050] This example serves to demonstrate that the premix combination of the present invention containing coir pith and surfactants provides enhanced wetting characteristics in plant growth media, such as potting soil, that the coir pith carrier alone does not provide.

[0051] Prepare potting soil consisting of 45% sphagnum peat, 45% composted bark powder, 10% perlite mix and divide into 3 batches. Apply the following treatments to the potting soil.

[0052] 1. Following the procedure described in Example 2, apply 4 fluid ounces per cubic yard of ACA 2000M Surfactant to the first batch of potting soil in the form of a 50% by weight premix composition of surfactant mixed with coir pith agent;

[0053] 2. The same amount of coir pith was applied to the potting soil as in Treatment I above, but no surfactant was mixed with the coir pith.

[0054] 3. Adopt the control sample without additive coconut fiber pith or surfactant as the third batch of potting soil.

[0055] After pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com