Module component

A technology for module components and components, which is applied in the fields of semiconductor/solid-state device components, electrical components, and electrical solid-state devices, and can solve the problems of overall performance impact and reliability damage of packaged components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

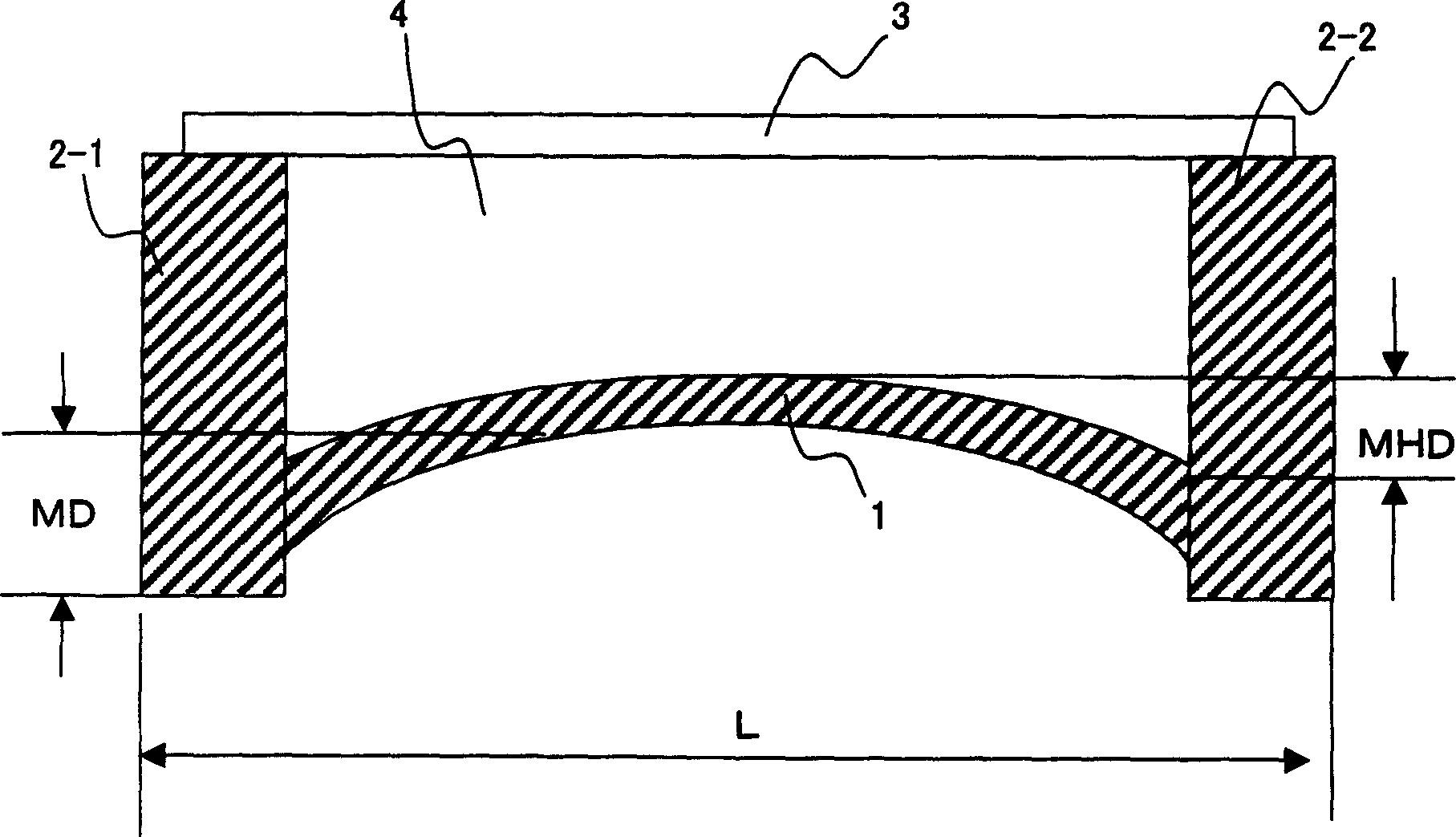

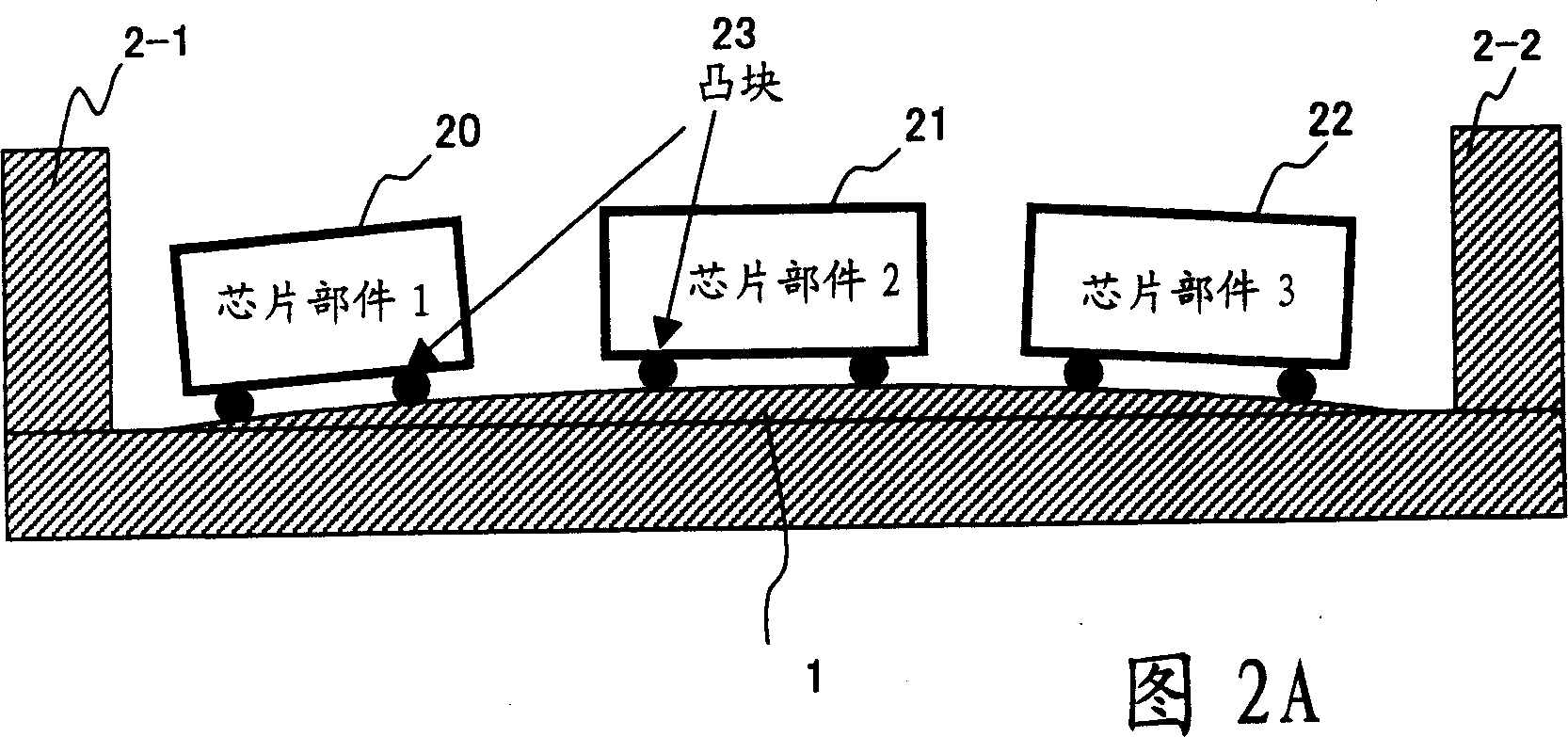

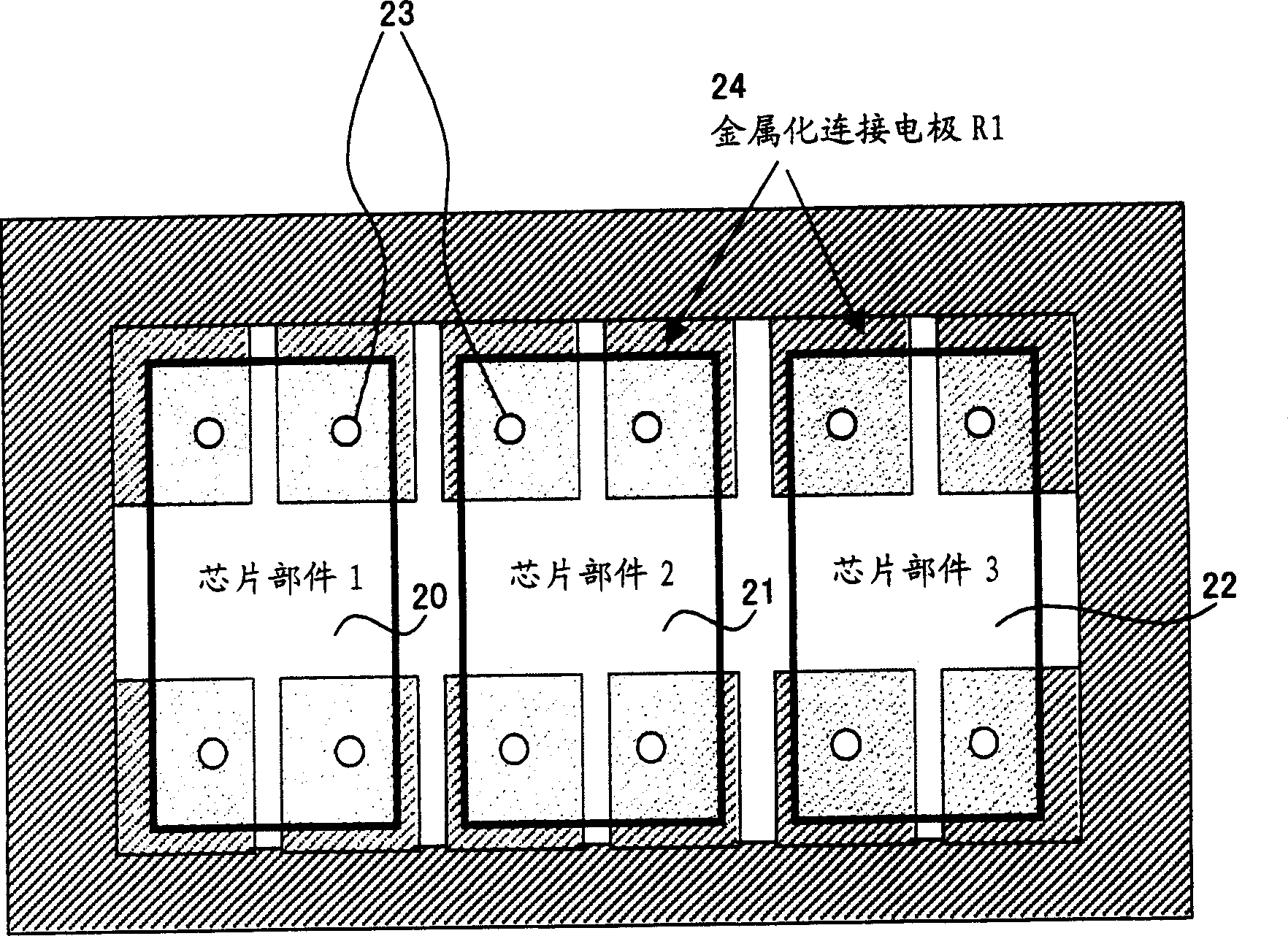

[0025] Figure 3 shows a first embodiment of the present invention. FIG. 3A is a cross-sectional view of the chip carrier with the cover 3 removed. Figure 3B is a top view of the chip carrier. Two chip components 20 , 21 are mounted on the chip carrier substrate 1 .

[0026] This embodiment is characterized in that the dimensions of the bumps 23-1, 23-2, which connect the plurality of chip components 20, 21 to the metal connected to the electrode 24.

[0027] More specifically, in the embodiment shown in FIG. 3 , a connection electrode 24 is metallized on the substrate 1 , and a plurality of chip components (two chip components in the case of FIG. 3 ) 20, 21 pass through bumps 23 -1, 23-2 are mounted on the connection electrode 24.

[0028] In addition, on the basis of the height of the bump 23-1 in the central area of the substrate 1 in the length direction of the substrate 1 (that is, the lateral direction in the figure), the bump (bump 23-1) is placed in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com