Active red SHE, synthetic method and its composite active red dye

A synthesis method and technology of reactive red, applied in the field of dyes, can solve the problems of complex production process, insufficient color yield, too much sewage, etc., and achieve the effect of reducing pollution links and reducing salting-out process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

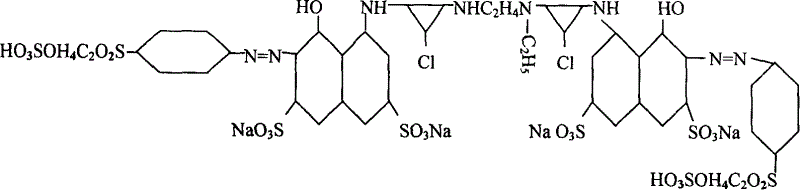

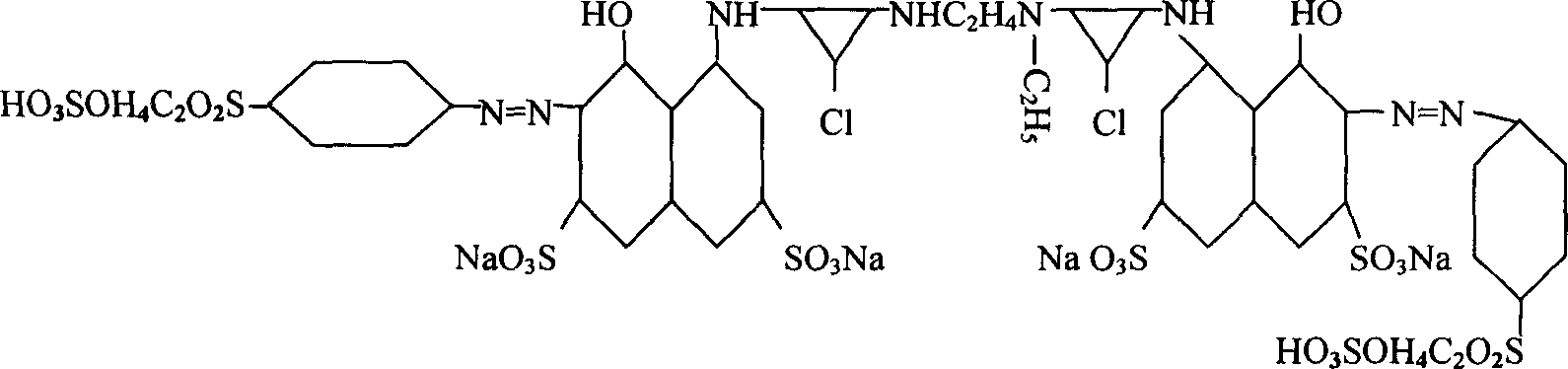

Image

Examples

Embodiment 1

[0010] Example 1, the p-(β-sulfate ethyl sulfone) aniline, hydrochloric acid, sodium nitrite, diazonium at 0 ~ 5 ° C, acid-base coupling with H, and then condensed with cyanuric chloride, and then with N-ethyl N-ethylethylenediamine is dicondensed, the ratio of N-ethylethylenediamine is 0.5, PH=8-9, the temperature is about 25-30°C, the dicondensed solution is concentrated by nano-membrane, and then sprayed dry to obtain Monomer reactive red SHE finished product.

Embodiment 2

[0011] Example 2, referring to Example 1, the ratio of N-ethylethylenediamine dicondensation during dicondensation is 0.6, pH=6.5-8, and temperature is between 22-28°C.

Embodiment 3

[0012] Embodiment 3, composite reactive red dyestuff, is made up of 90 parts of reactive red SHE monomers, 2 parts of dustproof agent, 8 parts of sodium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com