Toluene selective disproportionation and carbon 9 and above arene dealkytation method

A selective and dealkylation technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as high energy consumption, large circulation volume of xylene separation unit and isomerization unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

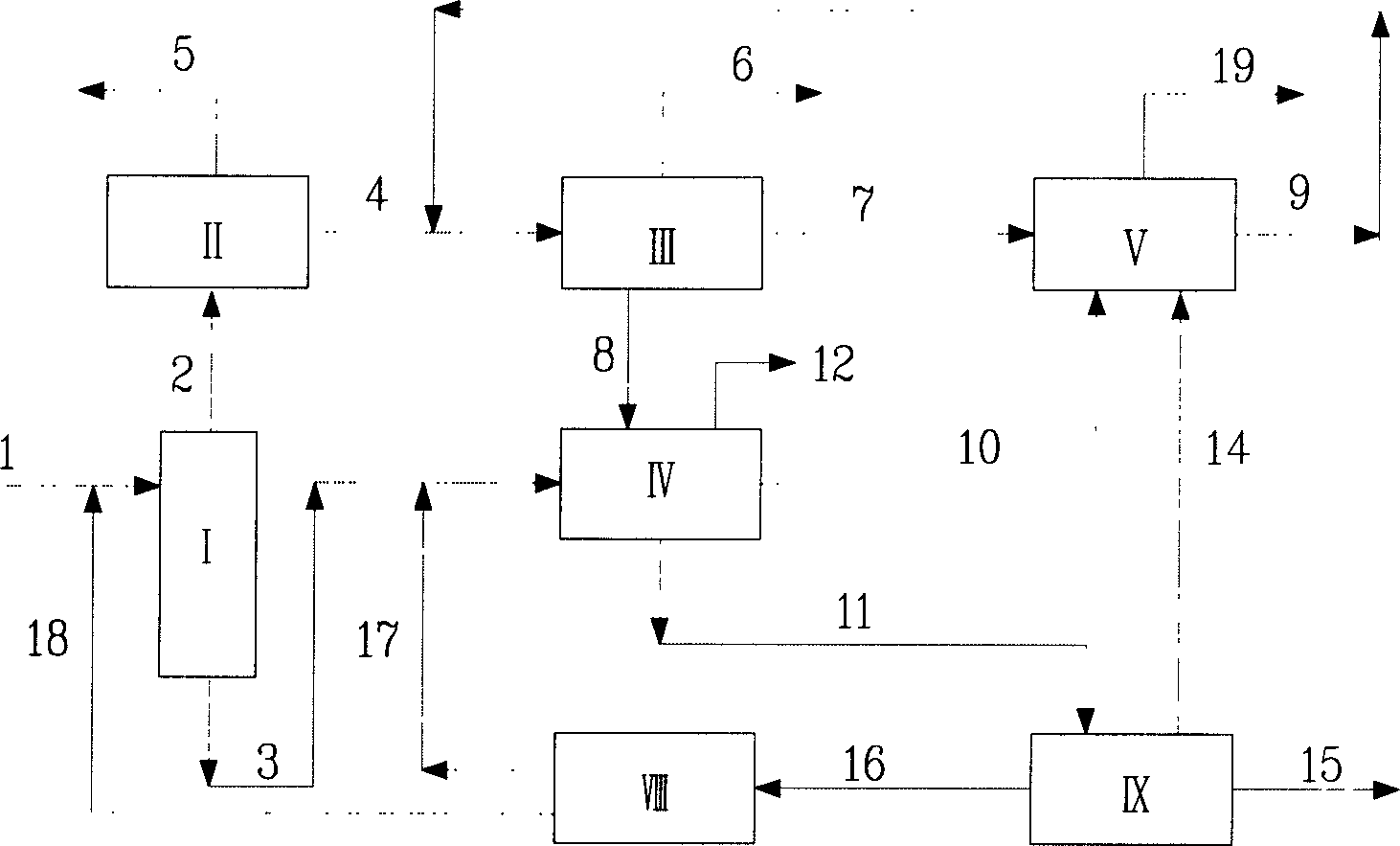

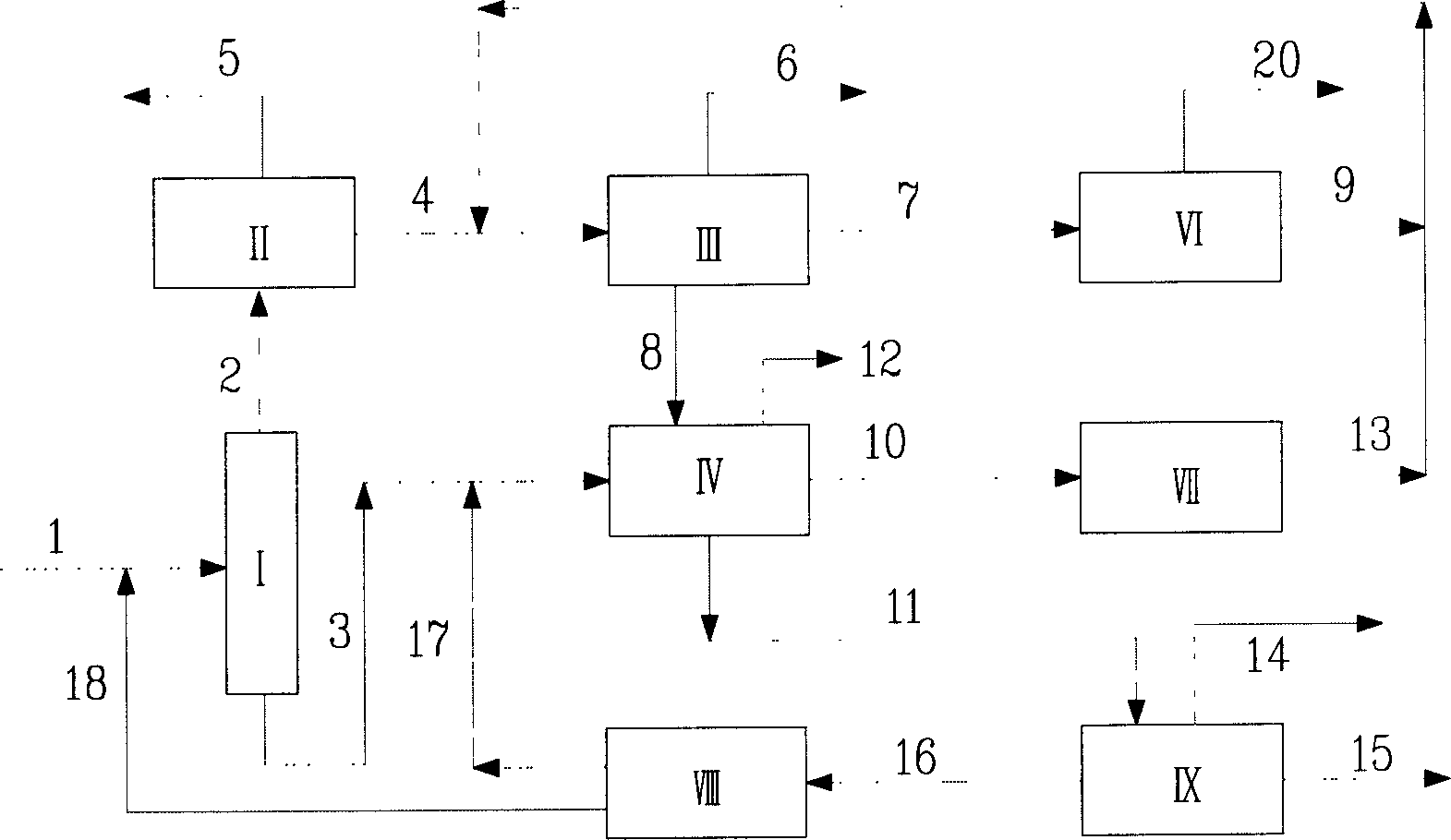

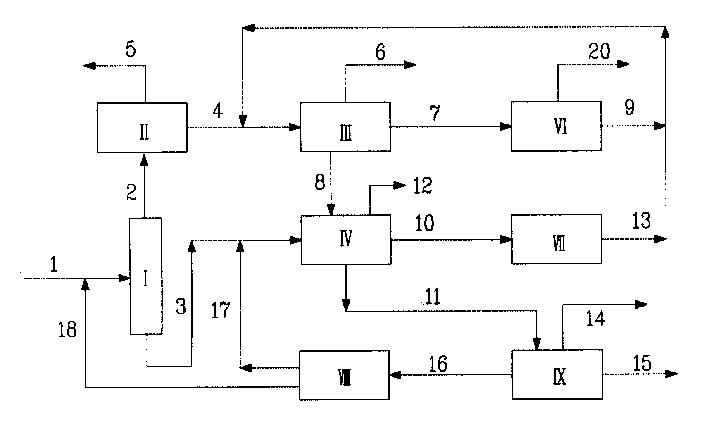

Method used

Image

Examples

Embodiment 1

[0027] Separating the mixed raw materials containing benzene, toluene, C8 aromatics, C9 and above aromatics and non-aromatics to obtain C9 and above aromatics, which are used as raw materials, under the condition of hydrogen, in a fixed bed reactor Carry out the investigation of the dealkylation reaction performance of aromatic hydrocarbons with carbon nine and above. The inner diameter of the reactor is φ25 mm, the length is 1000 mm, and it is made of stainless steel. The upper and lower sides of the catalyst bed are filled with φ3 mm glass beads for air distribution and support, and the reactor is filled with 20 grams of β-zeolite catalyst containing 0.05% bismuth. Aromatic raw materials are mixed with hydrogen and then passed through the catalyst bed from top to bottom for C 9 + A dealkylation reaction to generate benzene, toluene and C 8 A, the reaction temperature is 425°C, the pressure is 3.0Mpa, and the weight space velocity is 2.0 hours -1 , the molar ratio of hydr...

Embodiment 2

[0038] C in typical reformed depentanized oil 6 A~C 10 + The composition of each substance of hydrocarbon is the basic data, investigate the present invention according to the appended figure 2 The process flow shown shows the pX and benzene production capacity and the processing scale of each unit.

[0039] Table 3 shows the composition distribution of aromatics sent out from a typical reformer and the flow rate of each component used in this example.

[0040] composition

[0041] According to attached figure 2 The aromatics flow rate (fresh feed) in the technological process of the present invention described and table 3 and embodiment 1 carbon nine and above aromatics dealkylation reaction result and toluene selective disproportionation reaction result, the reaction of toluene selective disproportionation unit The product also enters the adsorption separation device for separation. The feed and discharge data of the toluene selective disproportionation unit,...

Embodiment 3

[0048] Still using the process flow, process conditions and catalyst of Example 2, taking the raw material composition shown in Table 3 as a benchmark, the raw material throughput was increased by 29%, and the flow rate of the raw material was shown in Table 7. Based on this, re-examine the ability of the process of the present invention to produce pX and benzene. The processing scale of each unit of the aromatics complex is shown in Table 8, and the production of p-xylene and benzene is shown in Table 9.

[0049] composition

[0050]

[0051] product

[0052] Compared with embodiment 2, embodiment 3 has increased the device processing capacity of 29%, and the total output of p-xylene and benzene has increased by 31.2%, and the processing scale of each unit, except the selective disproportionation unit not established in the comparative example, The processing scales of other units have not increased, and the closest processing scale is the xylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com