Weaving method for knitting fleece imitating effect of burnt-out print

A technology of knitting and production method, which is applied in the field of production of knitted jacquard terry to achieve the effect of increasing the variety of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

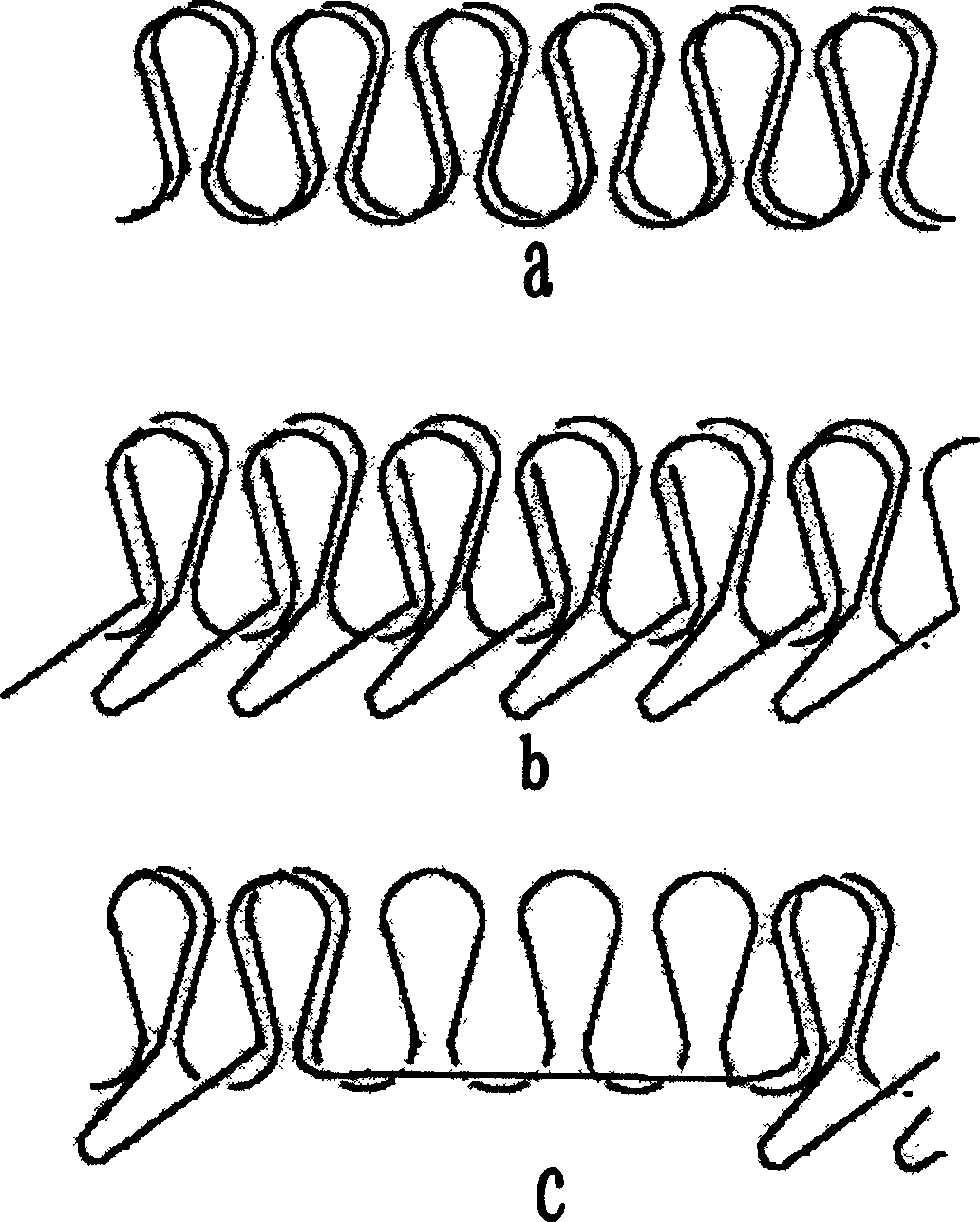

[0010] The specific embodiment and the steps of weaving imitation burnt-out effect jacquard terry pile of the present invention are as follows: use the cylinder needle 1 of vertical state and the dial needle 2 of horizontal state on the weft knitting machine ( figure 1 ), weave a burnt-out effect jacquard terry course in two ways. In the first path a, all the dial needles 2 do not come out of the needle, and all the cylinder needles 1 feed the ground yarn 3 after withdrawing the loop, and then the knitting needle 1 descends but does not take off the loop, that is, all the cylinder knitting needles There is a ground yarn 3 in the needle hook of 1; then in the second path b, the cylinder knitting needle 1 at the loop is selectively selected to feed the cushion loop yarn 4 again, and all the dial needles 2 are out of the needle at the same time To rest the terry yarn 4, then the selected knitting needle 1 simultaneously pulls the ground yarn 3 on the pad of the first road a and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com